Composite covered spandex yarns and preparation method thereof

A technology of covering yarn and spandex, which is applied in the direction of yarn, textile and paper making, to achieve the effect of shortening the balance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

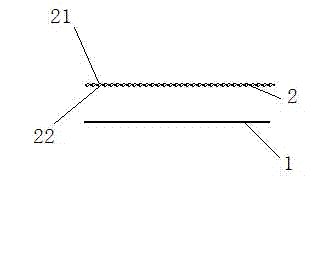

[0015] Such as figure 1 As shown, the present invention includes a spandex core filament 1 and a yarn 2 wrapped outside the spandex core filament 1 . The yarn 2 wrapped outside the spandex core yarn is composed of chemical fiber filaments 21 and natural fibers 22 after twisting, and the twist is 80 twists / meter.

[0016] The preparation method of spandex composite covered yarn comprises the following steps:

[0017] (1) Paralleling: Parallel the two fiber yarns (20+ Nylon 30 / Cotton 80 varieties) on a draft twisting machine and apply weak twisting, the speed is 500 m / min, and the twist is 80 twists / m;

[0018] (2) Coating: the above-mentioned weakly twisted yarn is coated on 20D spandex yarn, the spindle speed is 12000 rpm, the twist is 600 twists / m, and the draft is 3.0 times;

[0019] (3) Heat setting: put the covered yarn obtained in step (2) in a vacuum pre-shrinking tank, close the vacuum pre-shrinking tank and start vacuuming, drop the air pressure in the tank to 120mmH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com