Roller-type washing and drying machine

A washing-drying, drum-type technology, applied in washing devices, other washing machines, washing machines with containers, etc., can solve problems such as loud drainage noise, discomfort, and decreased drainage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

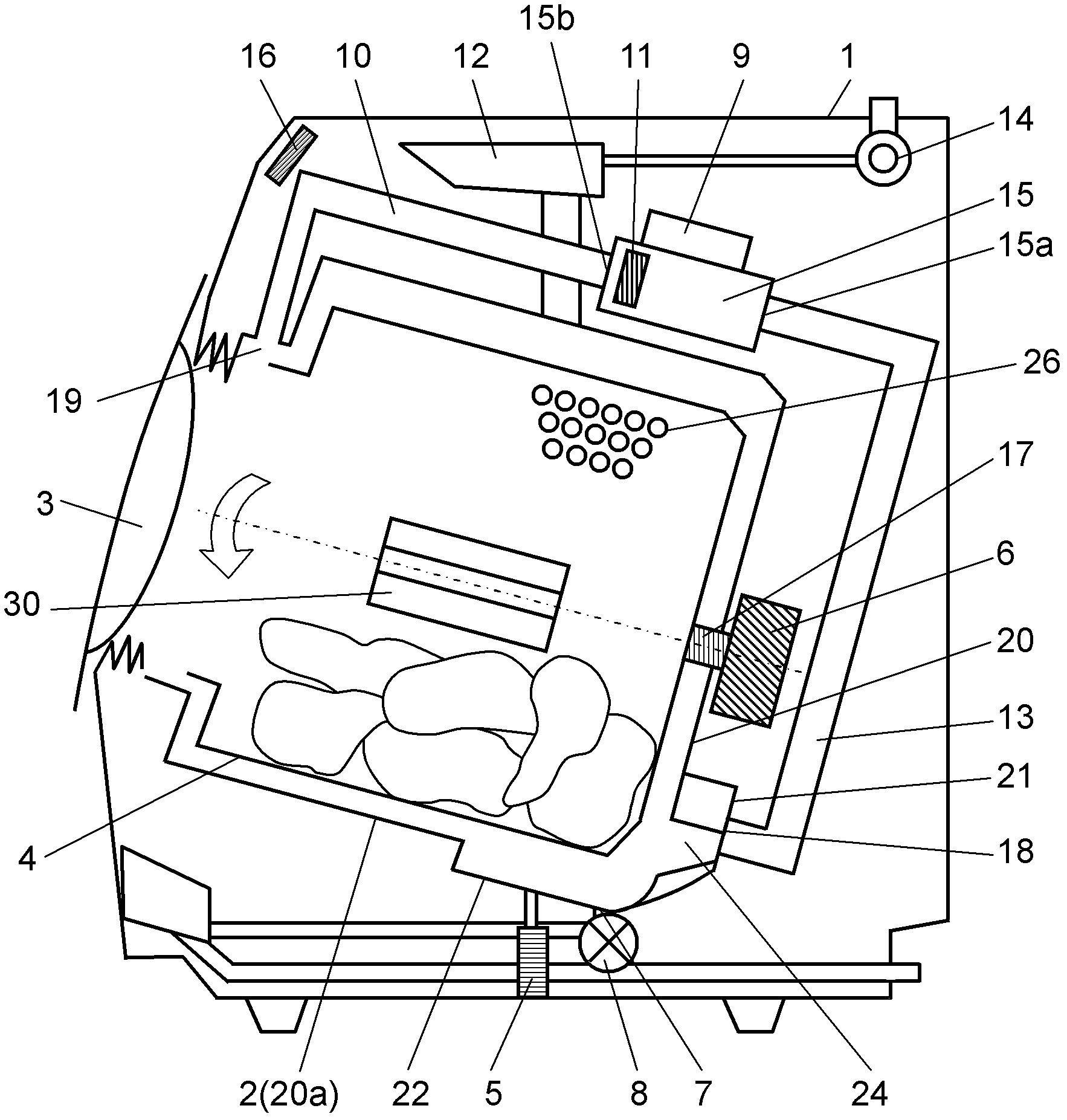

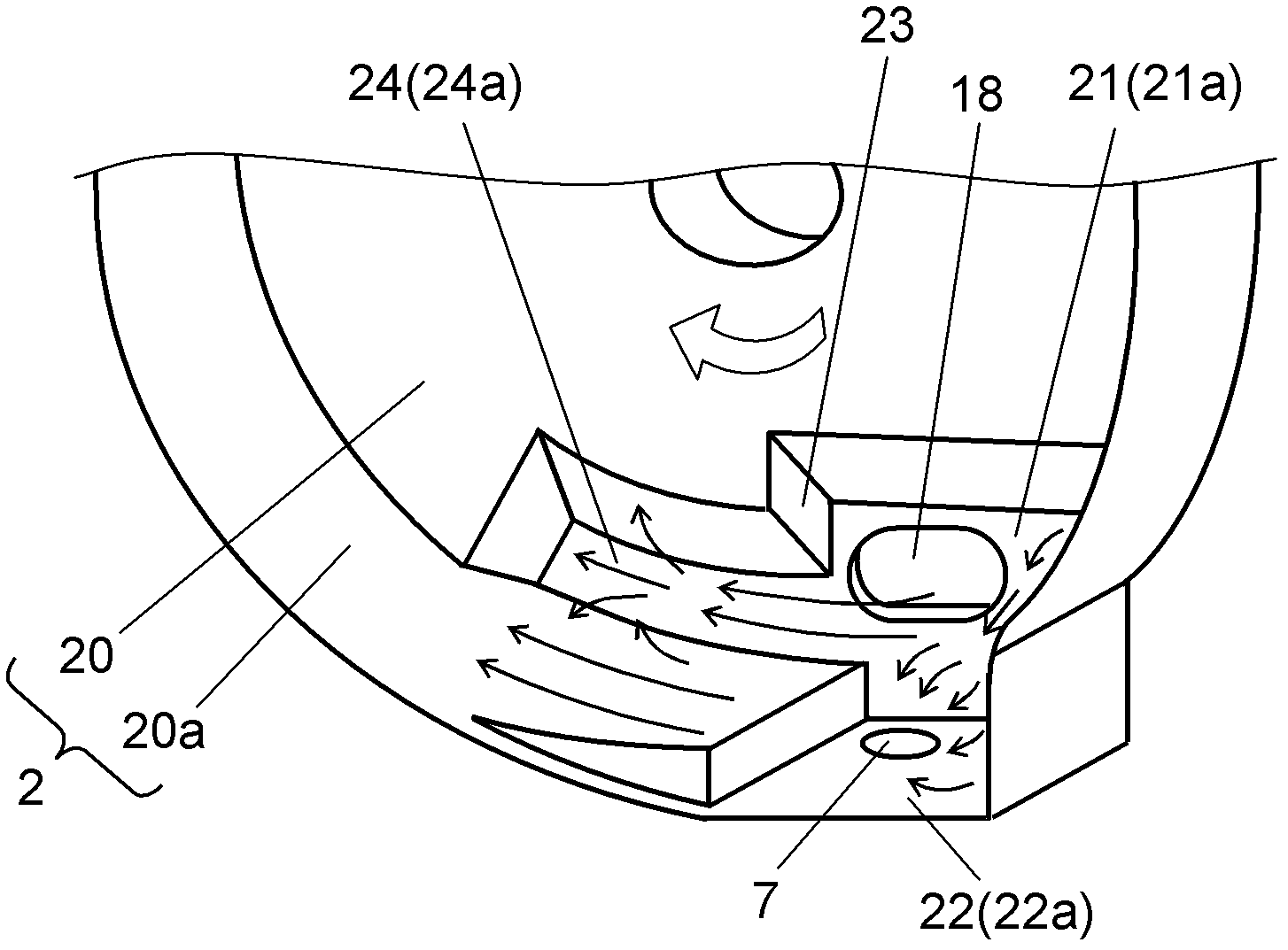

[0032] figure 1 It is a longitudinal sectional view of the drum type washing and drying machine in Embodiment 1 of this invention. figure 2 It is a partial detailed perspective view explaining the internal structure of the water tank of the drum type washing and drying machine in this embodiment.

[0033] Such as figure 1 As shown, the drum type washing and drying machine of this embodiment at least includes in the main body 1: a bottomed cylindrical water tank 2; a bottomed cylindrical rotating drum arranged in the water tank 2 in a freely rotatable manner. 4; and the cover 3 provided on a part of the main body 1 for taking and placing the laundry. A plurality of through-holes 26 are provided on the entire surface of the outer peripheral portion of the bottomed cylindrical rotating drum 4 , and are rotatably arranged in the water tank 2 . In addition, a plurality of protruding plates 30 are provided on the inner wall surface of the bottomed cylindrical rotating cylinder...

Embodiment approach 2

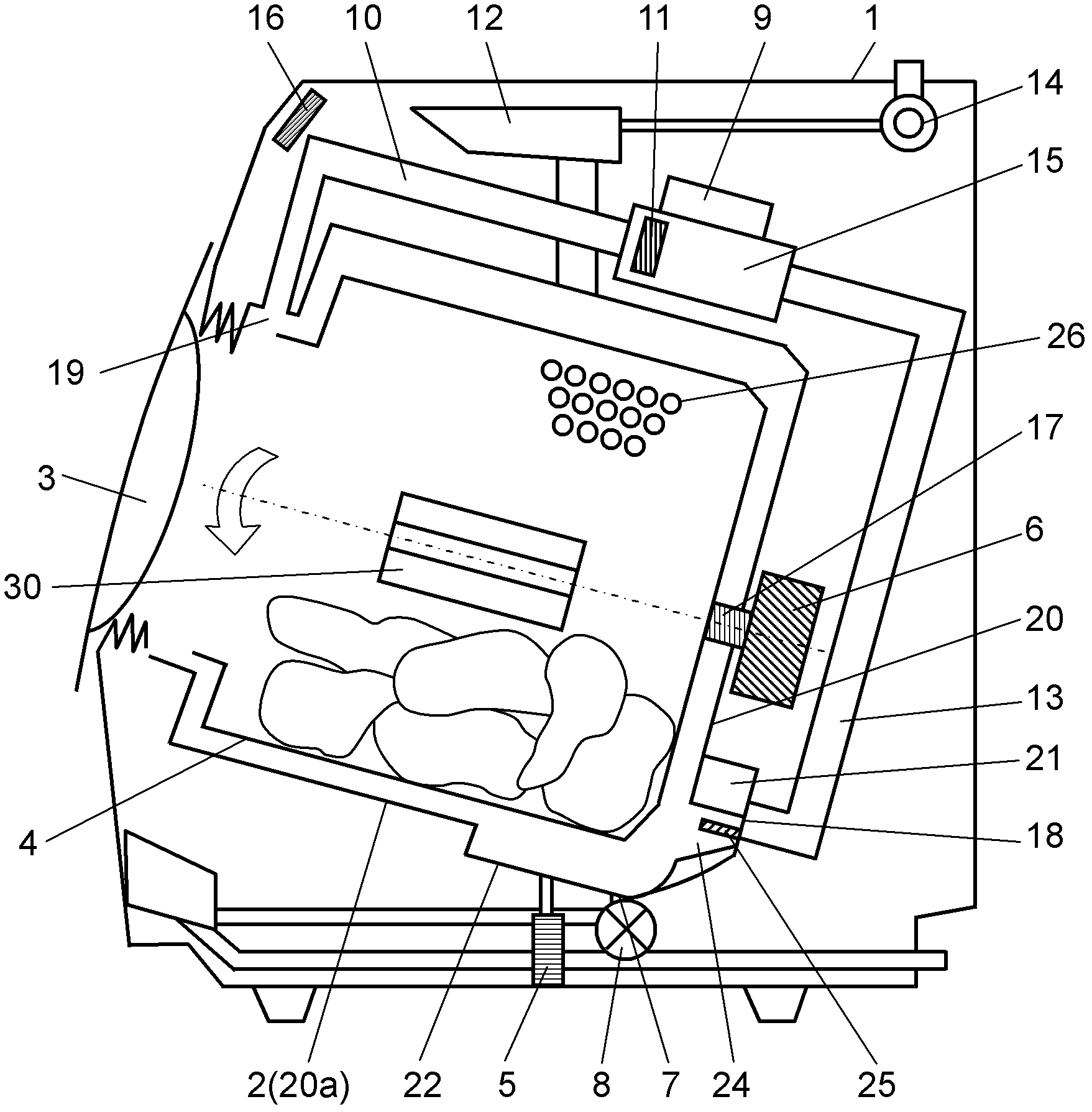

[0068] Below, use image 3 and Figure 4 , the drum-type washing and drying machine according to Embodiment 2 of the present invention will be described.

[0069] image 3 It is a longitudinal sectional view of the drum type washing and drying machine in Embodiment 2 of this invention. Figure 4 It is a partial detailed perspective view explaining the internal structure of the water tank of the drum type washing and drying machine in this embodiment.

[0070] Such as image 3 and Figure 4 As shown, the drum type washing and drying machine of the present embodiment is different from the first embodiment in that ribs are provided in the rotation direction along the water channel. The other configurations, functions, etc. are the same as those in Embodiment 1, and therefore description thereof will be omitted.

[0071] That is, if image 3 and Figure 4As shown, in the bottomed cylindrical water tank 2 , a part of the lower side of the substantially cylindrical side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com