Patents

Literature

45results about How to "Reduce drainage noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

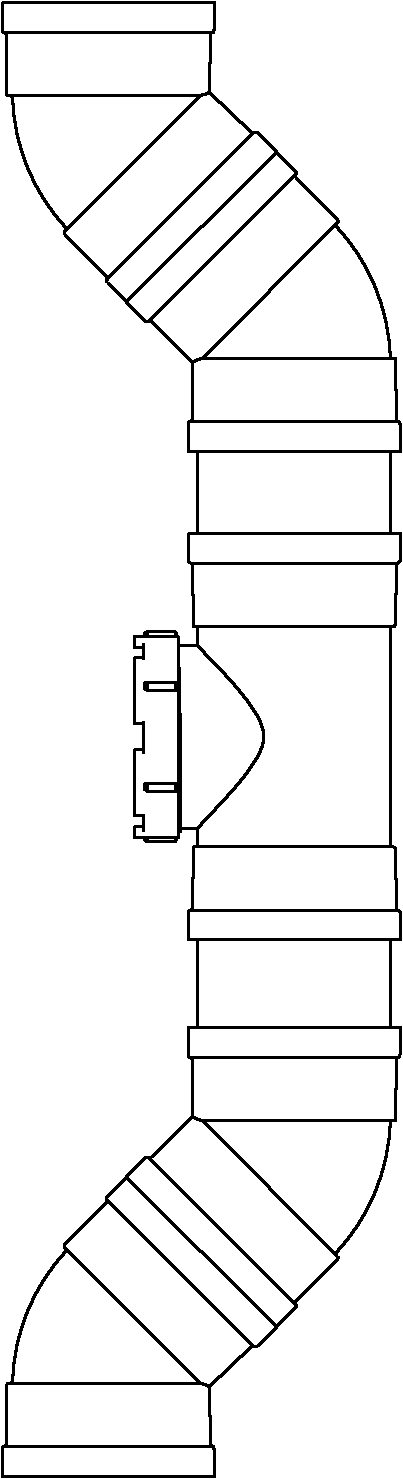

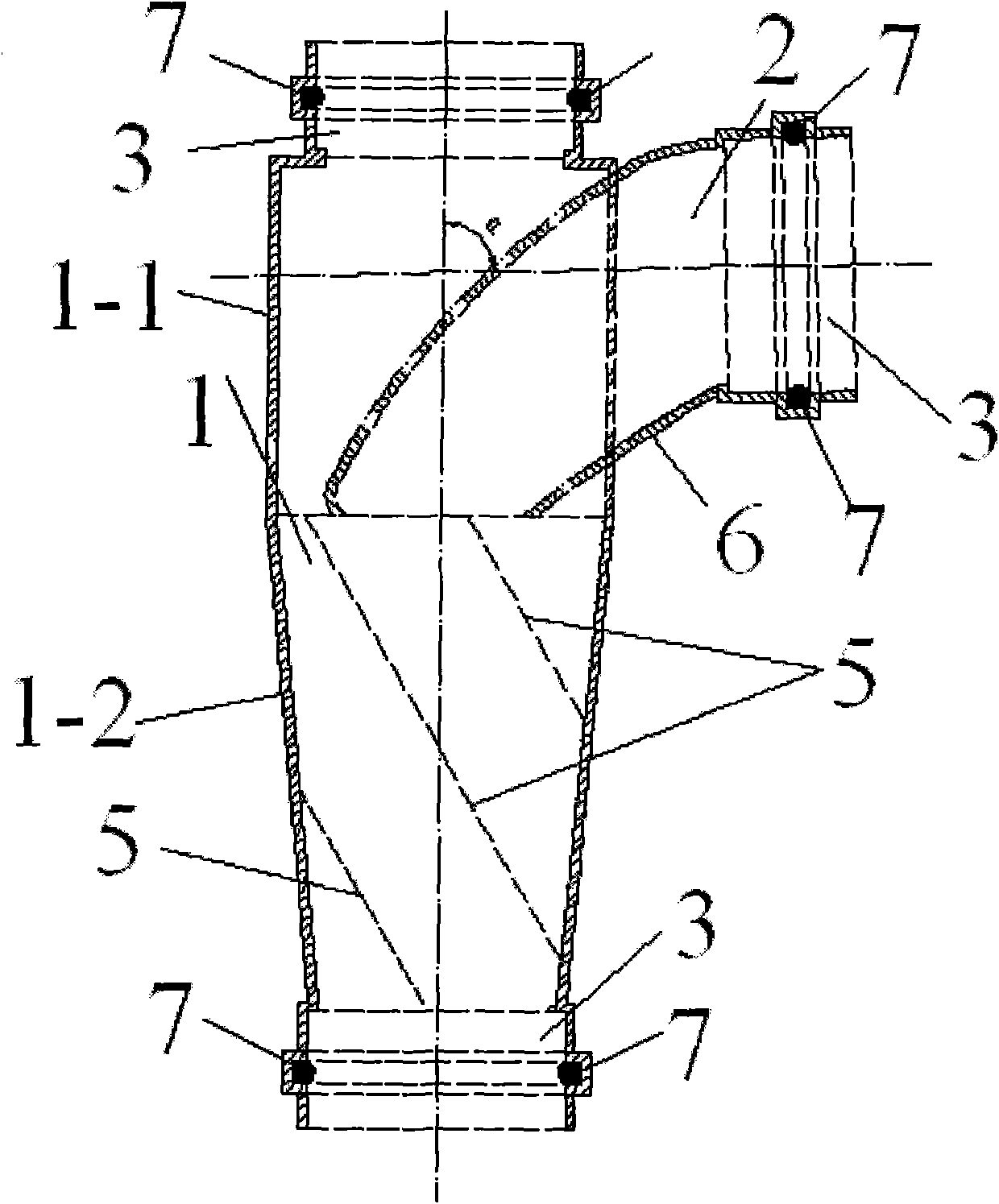

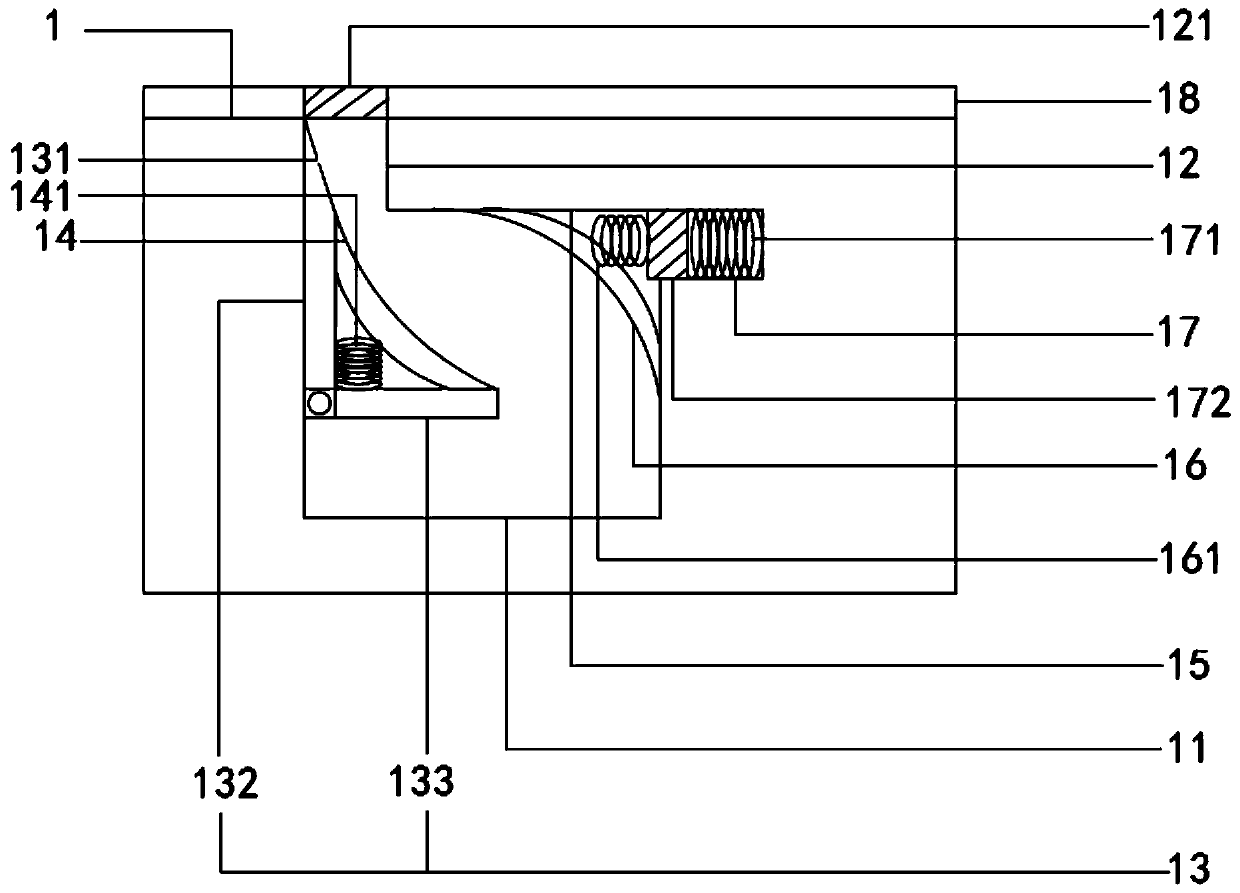

Energy dissipator for architectural drainage system

ActiveCN101846225AAvoid left and right conflictAvoid flow disorderDomestic plumbingPipe elementsVertical tubeWater flow

The invention discloses an energy dissipator for an architectural drainage system. A simple and easy energy dissipation device used at present has the defects of large drainage noise, space occupation of a piping shaft and the like. The energy dissipator for the architectural drainage system is characterized in that an inner cavity of a main body is provided with two arc-shaped water flow baffle plates arranged up and down, the arc shapes of the water flow baffle plates are downward, and the width of the water flow baffle plates is 1 / 3 to 2 / 3 of the width of the main body; and the upper part of the main body is provided with a stand pipe switching-in port, the stand pipe switching-in port is communicated with the inner cavity of the main body, the lower part of the main body is provided with a stand pipe switching-out port which is communicated with the cavity of the main body. The invention can effectively eliminate the energy of water flow, can also lower the drainage noise and decreases the space of the piping shaft.

Owner:浙江中财管道科技股份有限公司

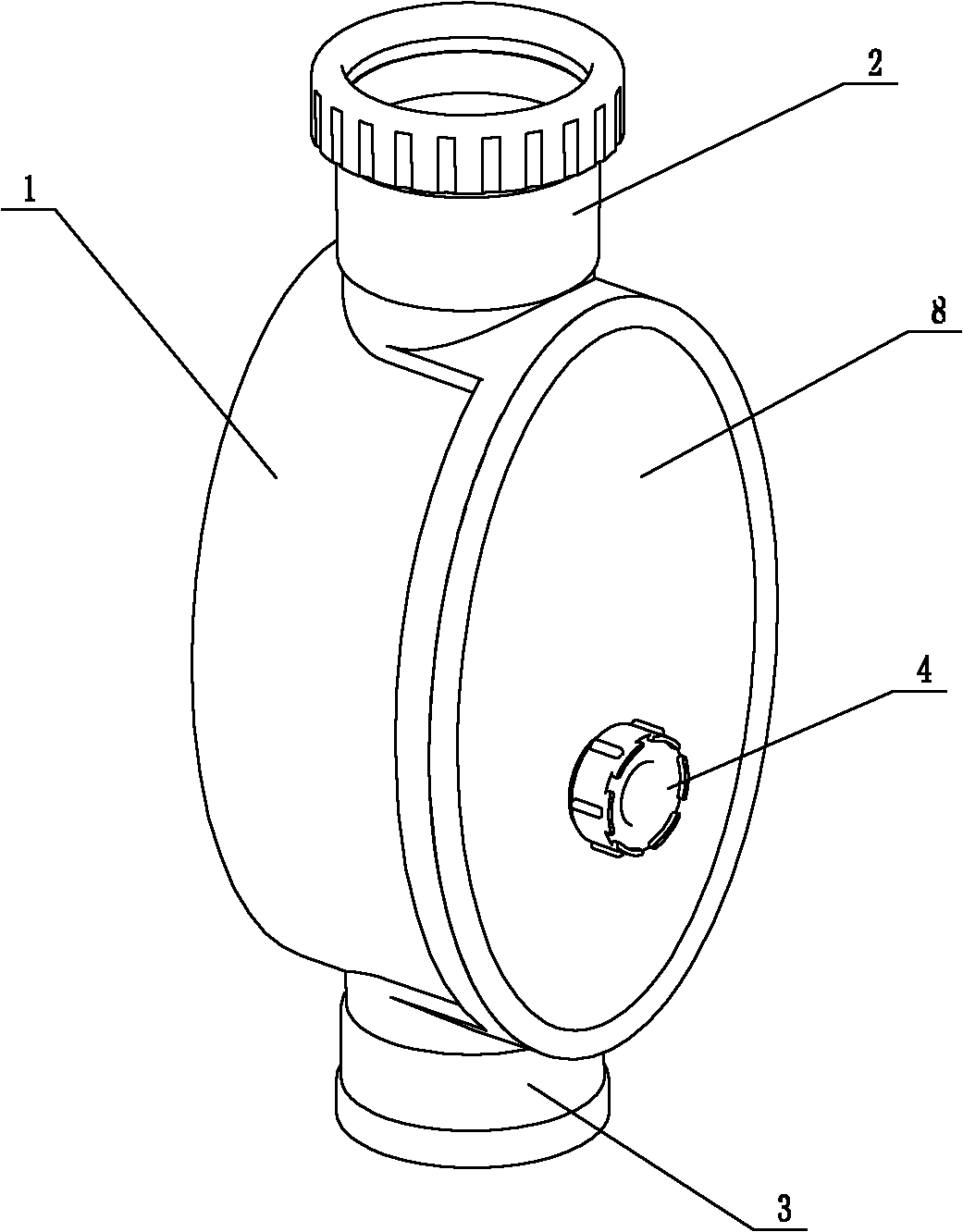

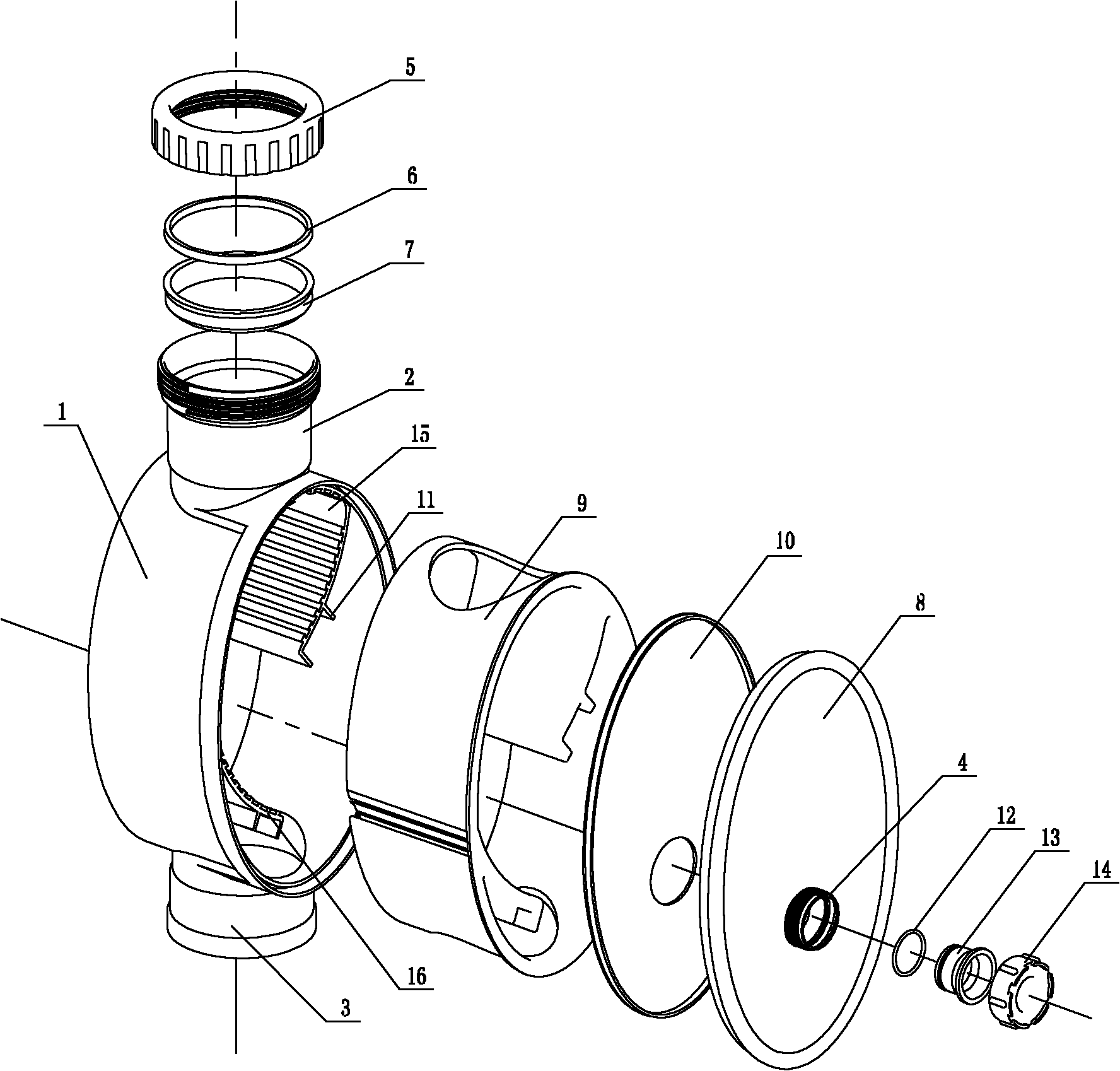

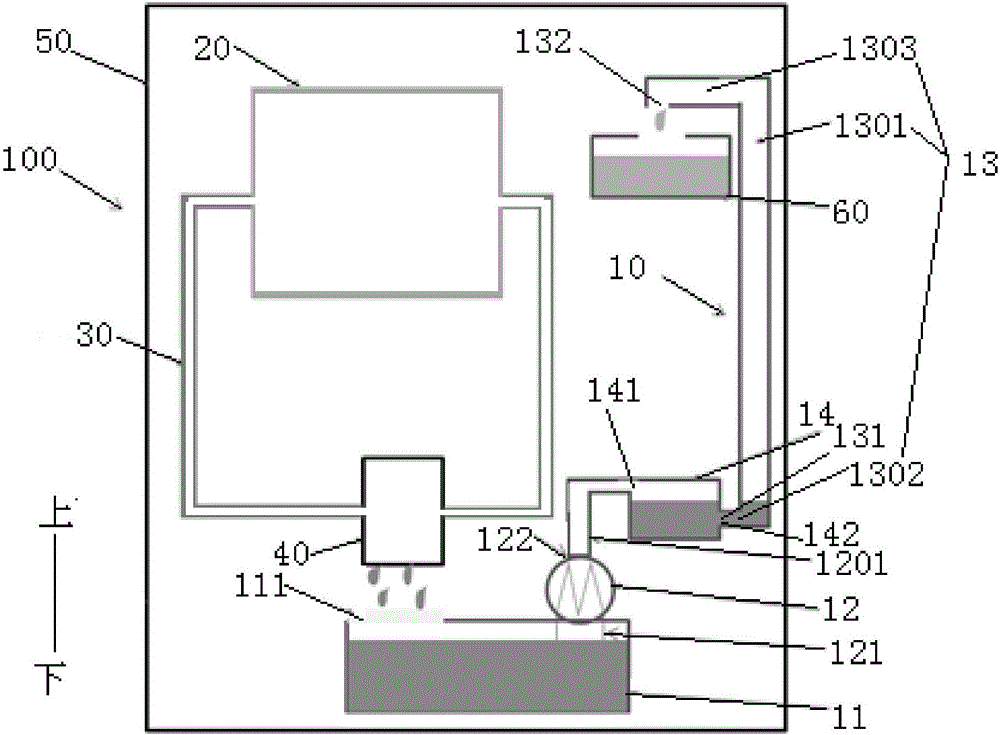

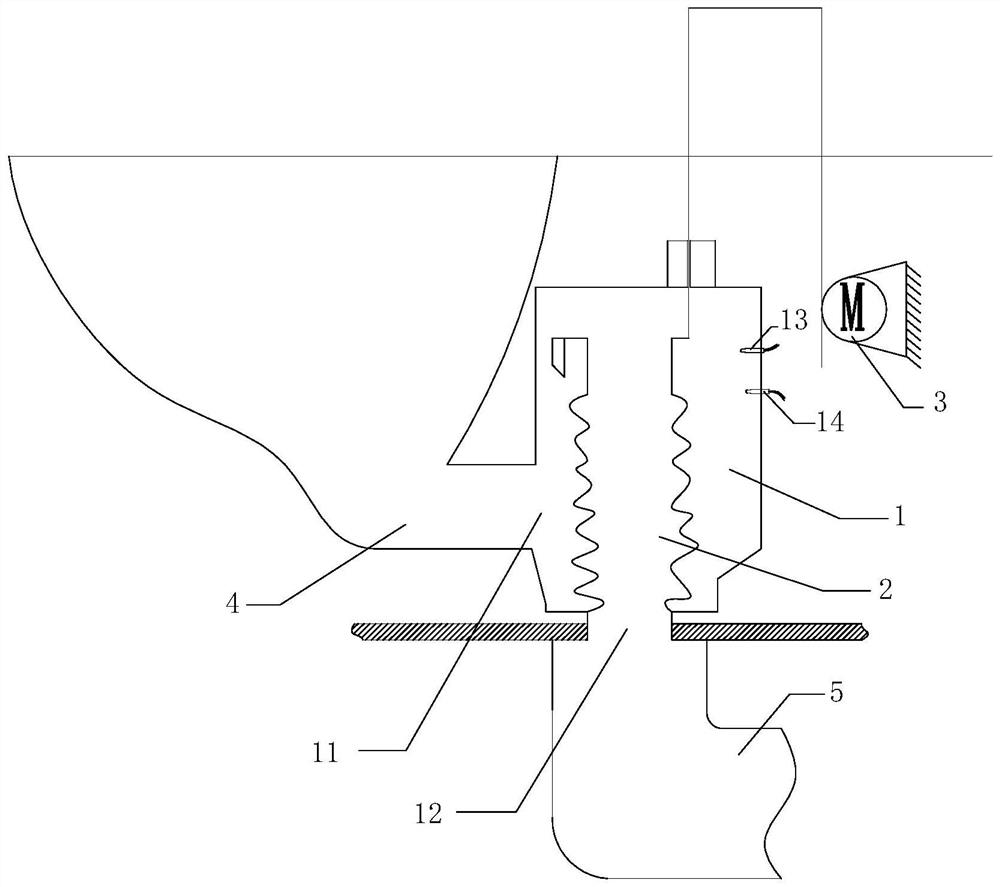

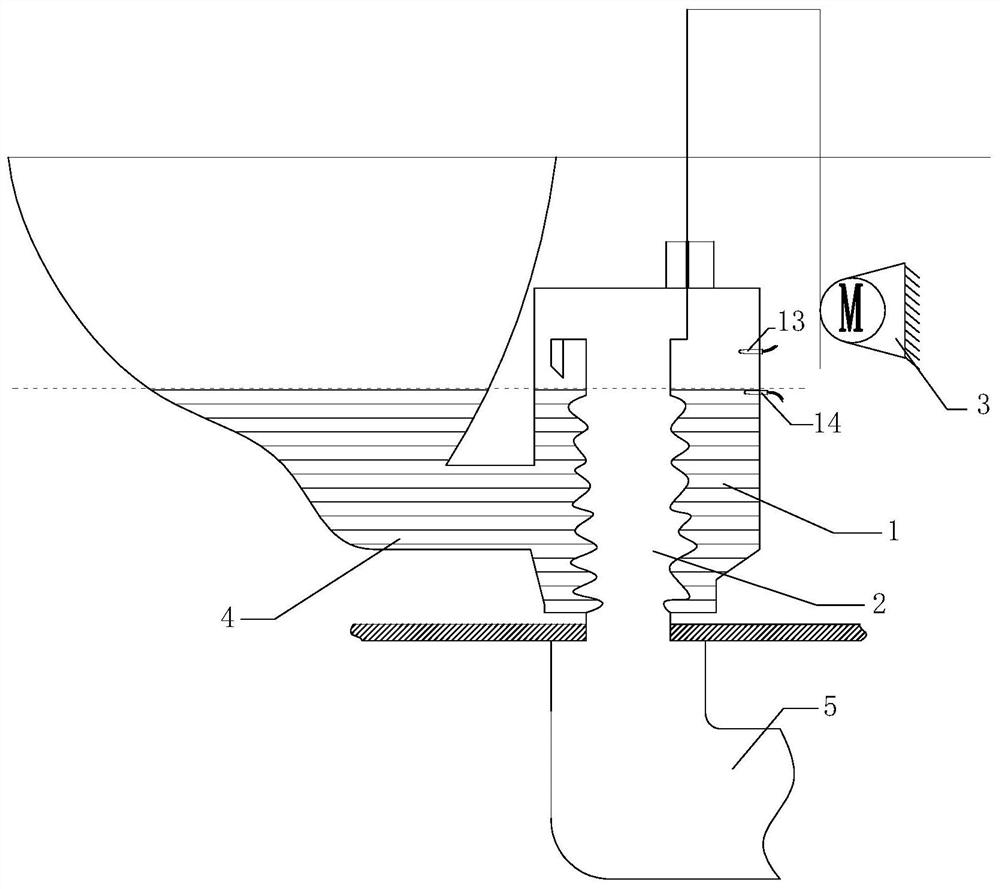

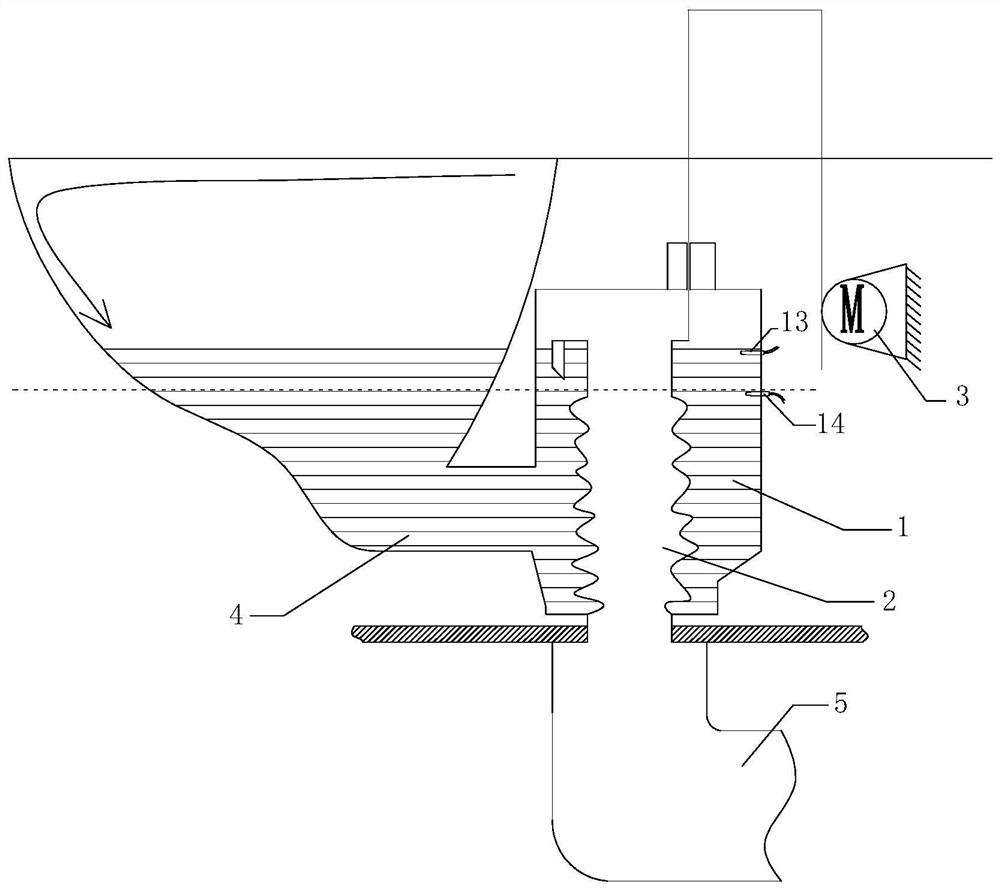

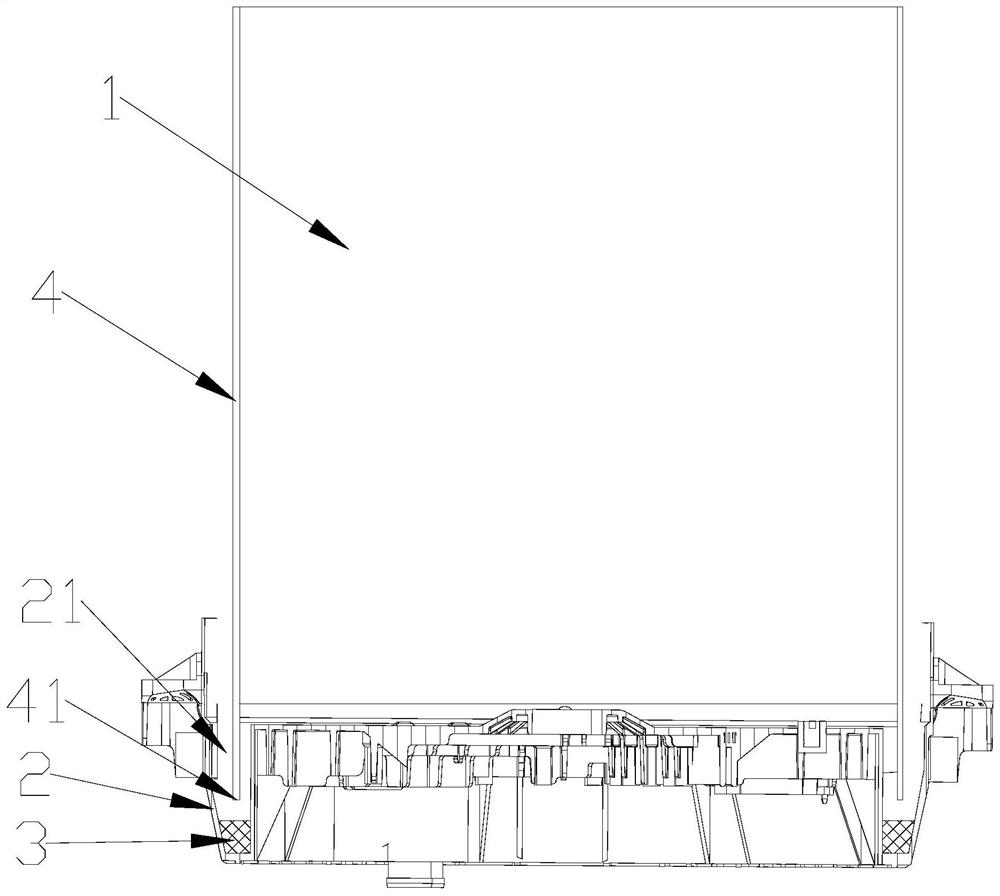

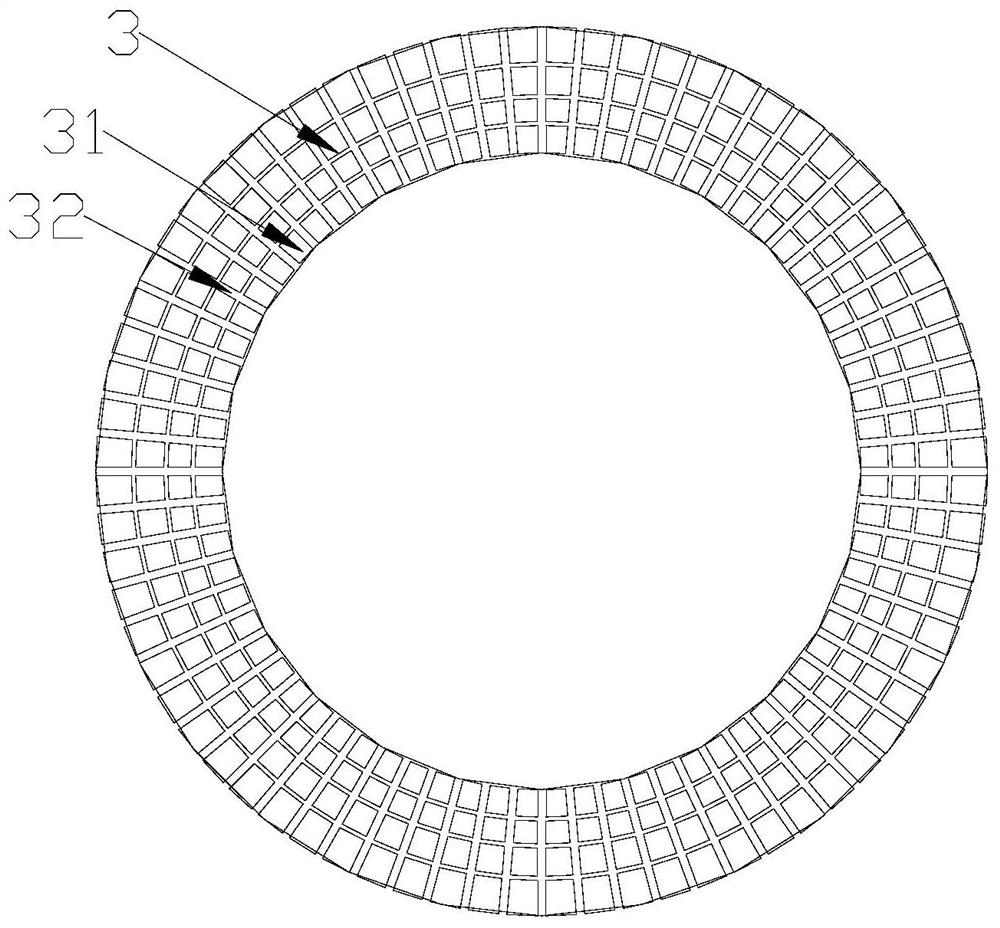

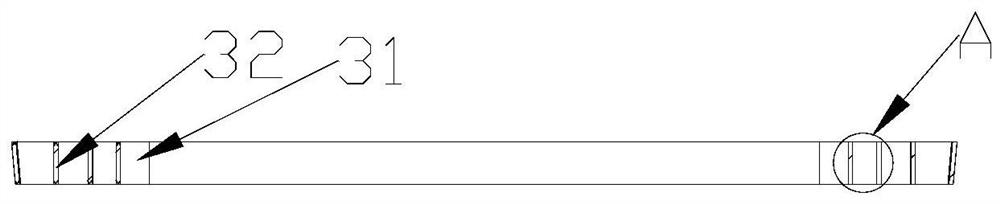

Draining filtering apparatus and household electrical appliance

ActiveCN104928893ASimple structureLarge filter areaTableware washing/rinsing machine detailsOther washing machinesImpellerWater flow

The invention discloses a draining filtering apparatus including an impeller driven by a motor, a housing and a filter, a drainage chamber for receiving the impeller and a filter chamber for receiving the filter are arranged in the housing, a water inlet is arranged in the filter chamber, a water outlet for communicating the filter chamber and the drainage chamber is arranged in the filter, and the draining filtering apparatus is characterized in that the filter includes a buffer part for buffering the water flow entered into the water inlet and a filtering part for filtering impurities in the water flow. During the filtering drainage, the water flow enters into the filter chamber in a rush, and the buffer part can buffer the rushed water flow to make the water flow directly hit the filtering part smoothly, so that the impurities in the water flow cannot pass through the filtering part and can deposit naturally in the filter chamber. Therefore, the filtering effect of the filtering apparatus can be greatly improved. The invention further discloses a household electrical appliance with the draining filtering apparatus.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

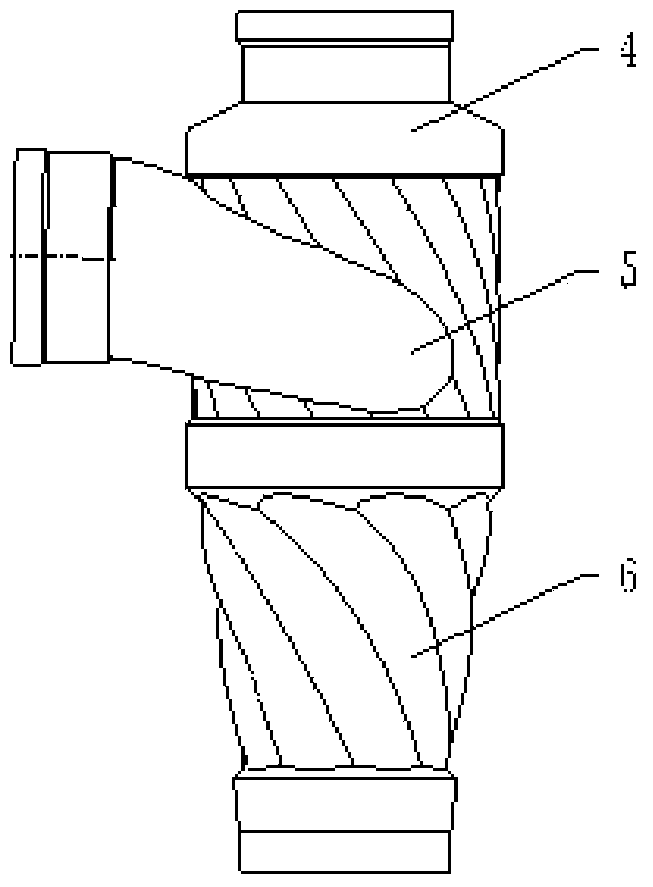

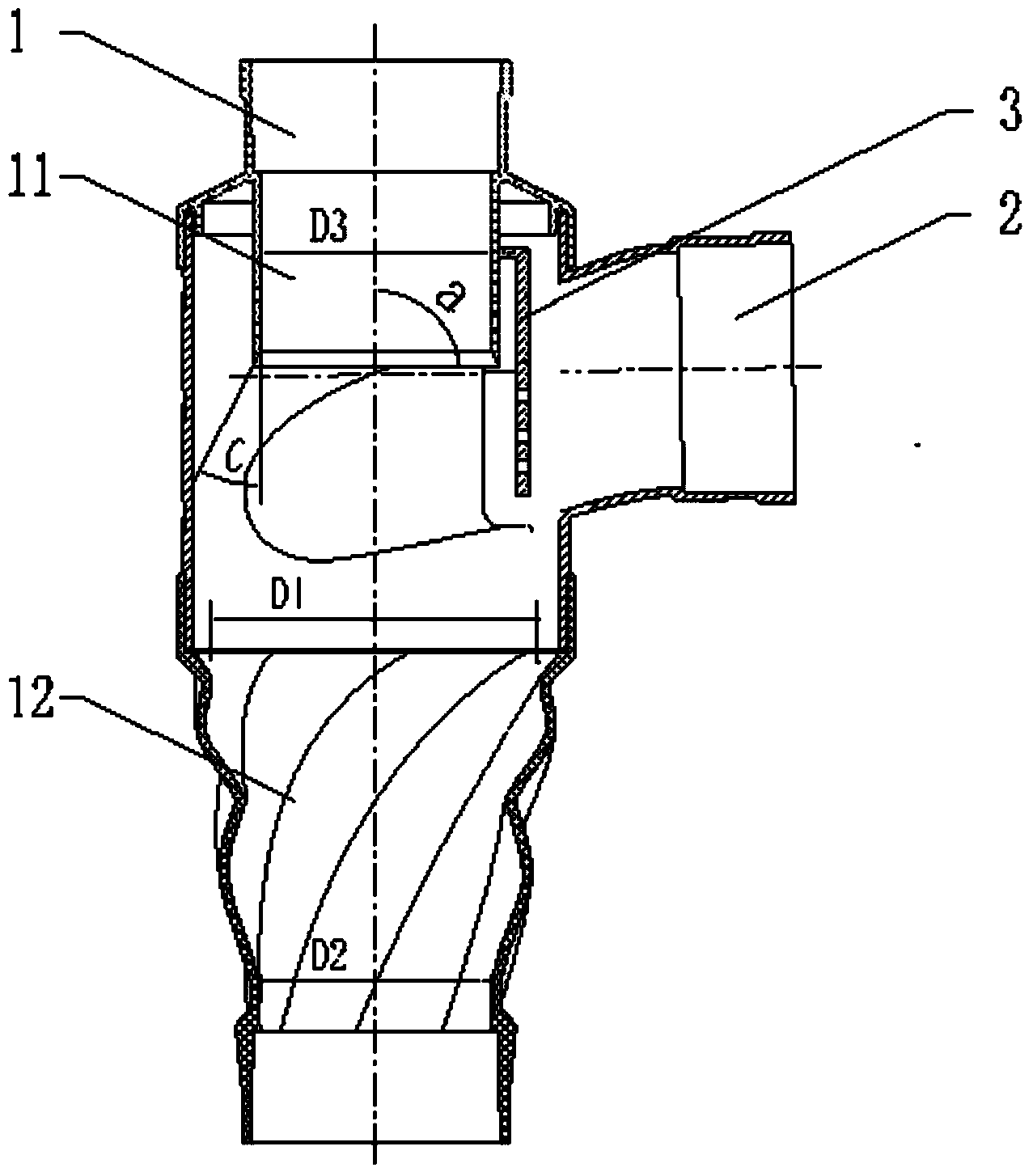

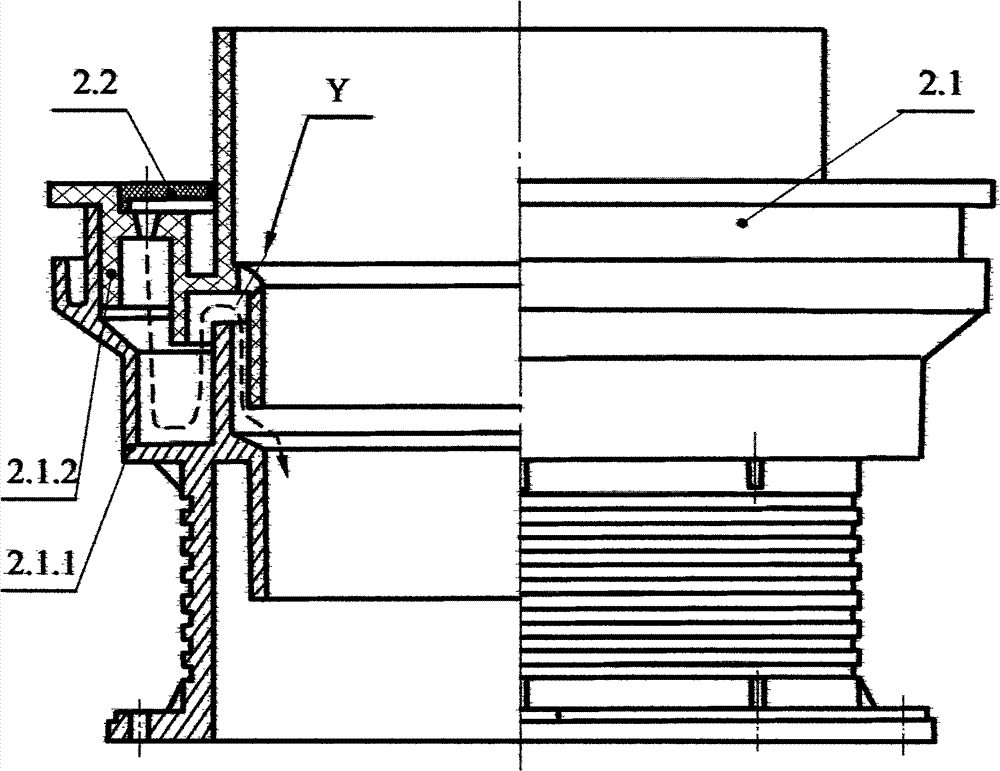

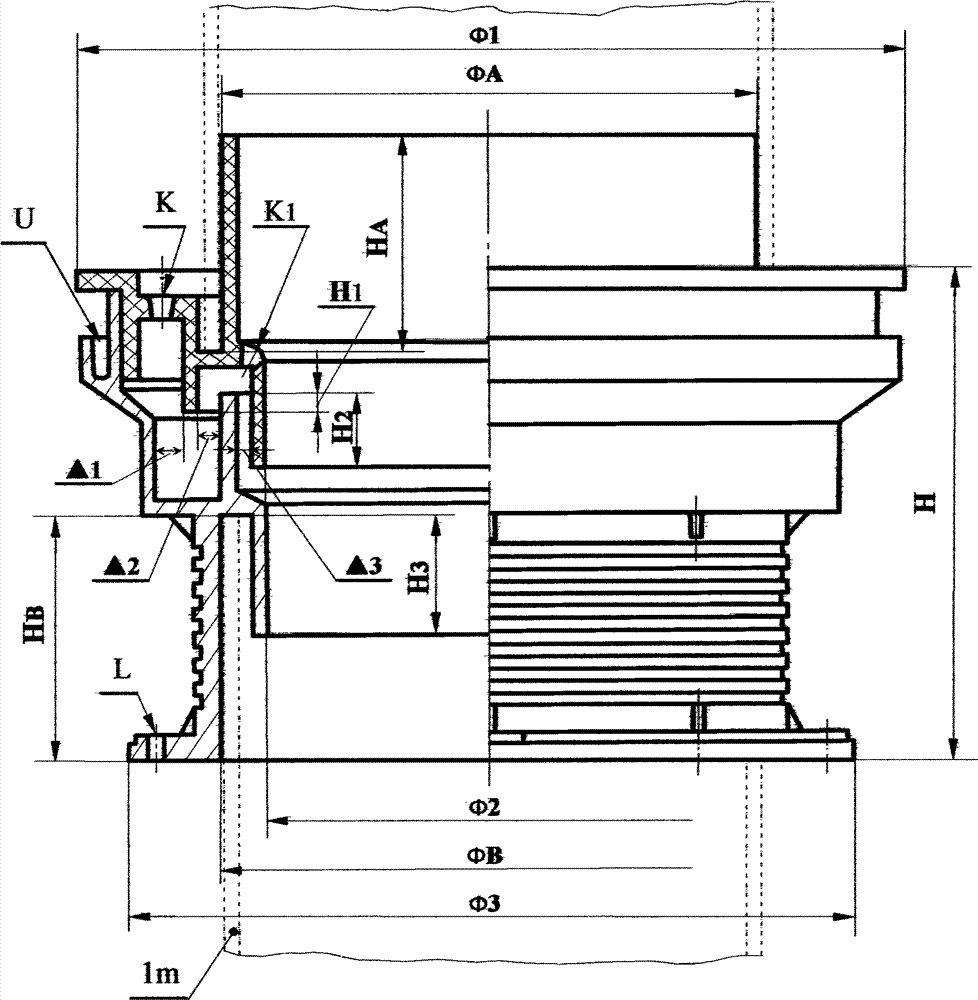

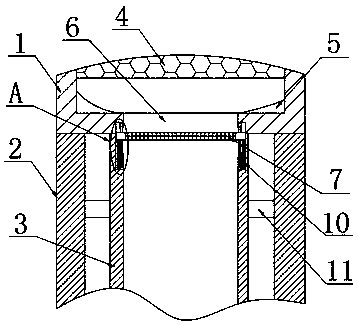

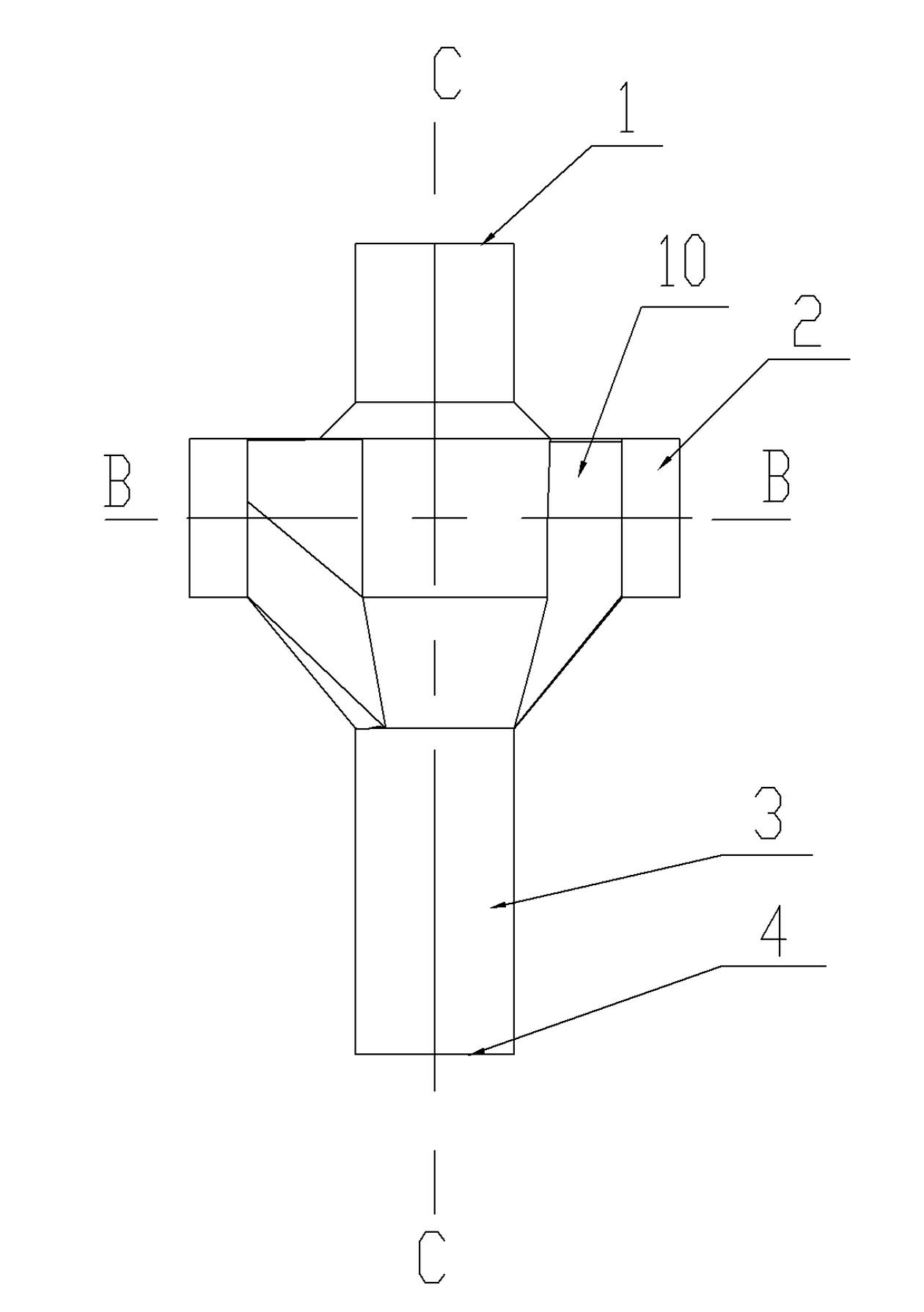

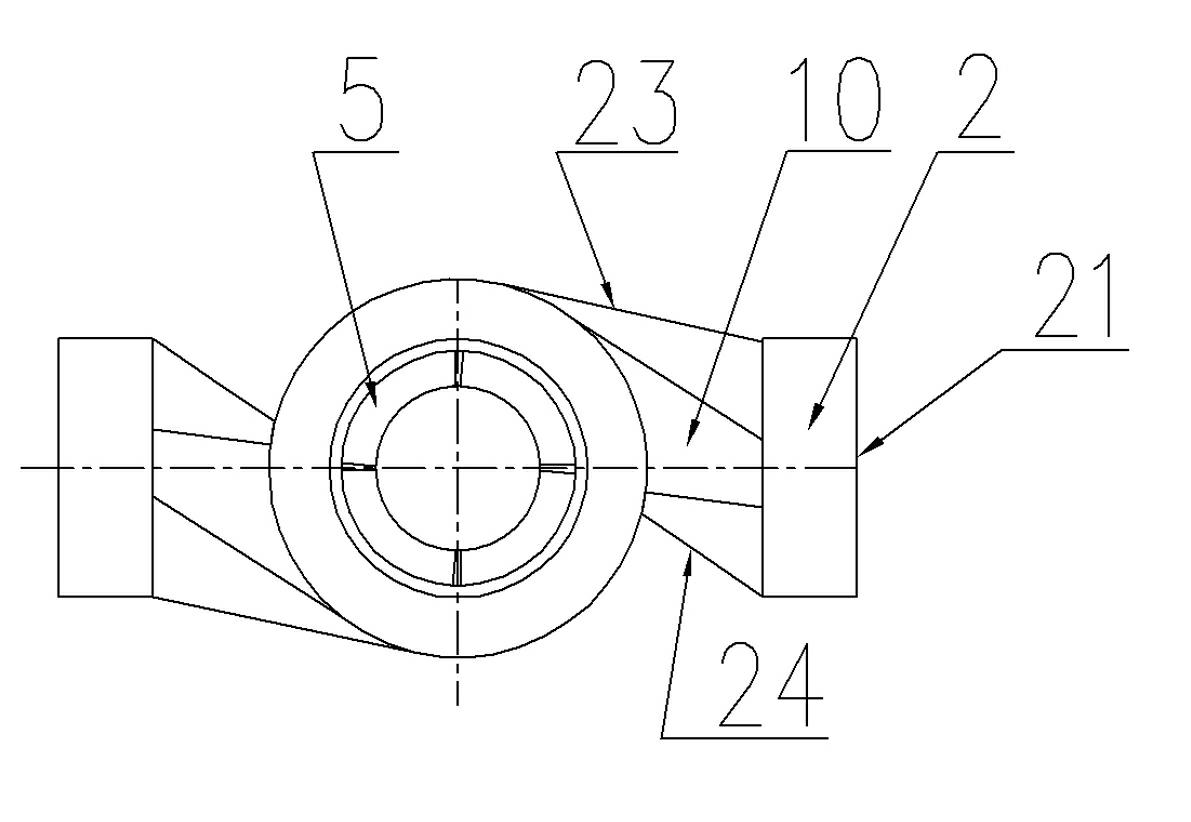

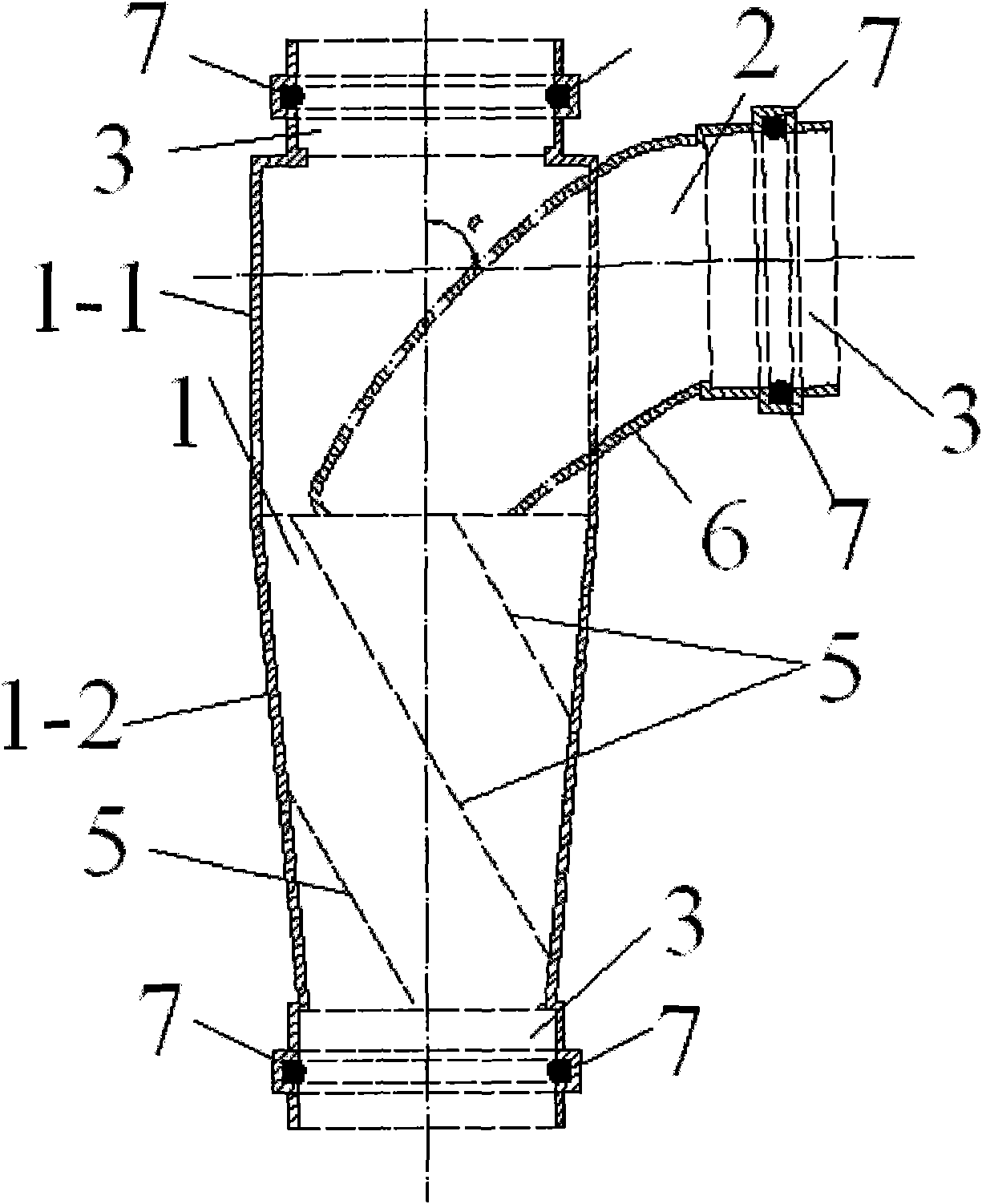

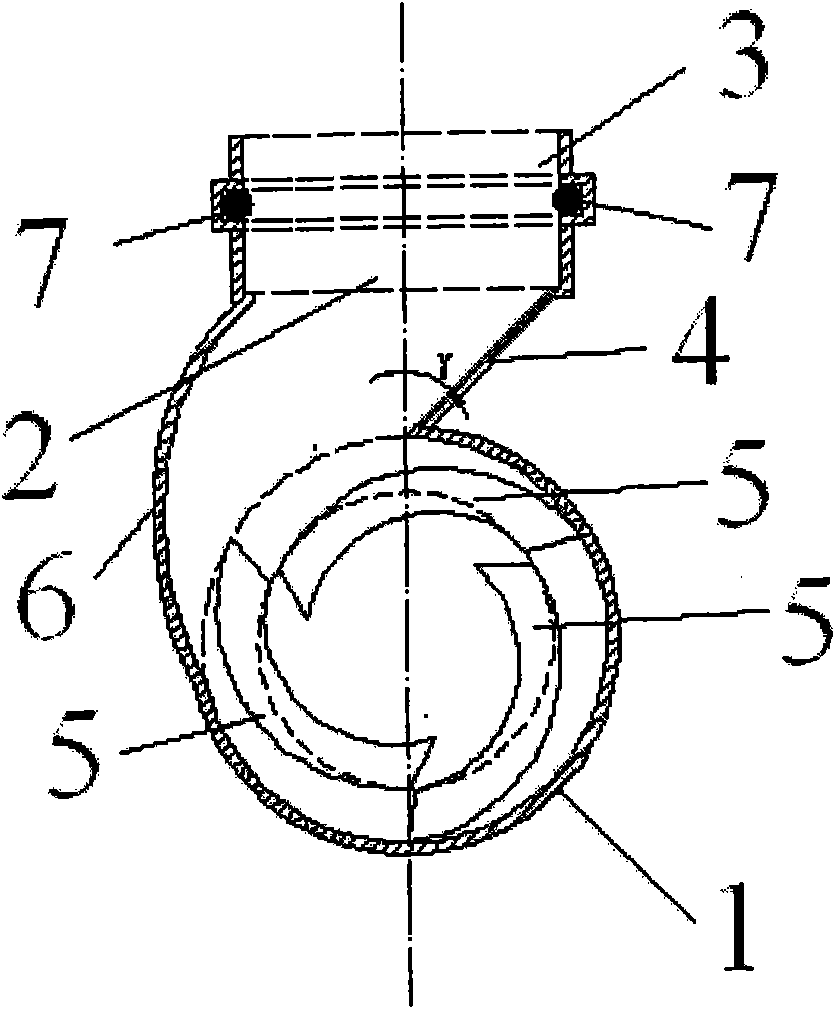

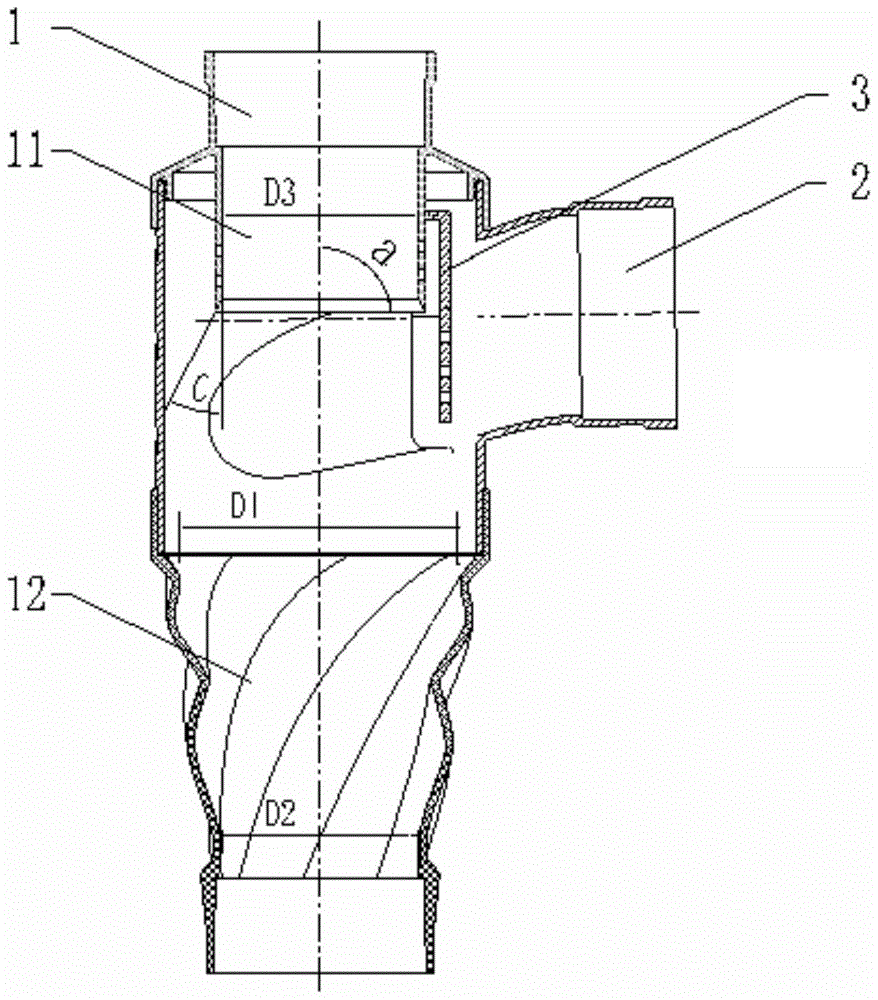

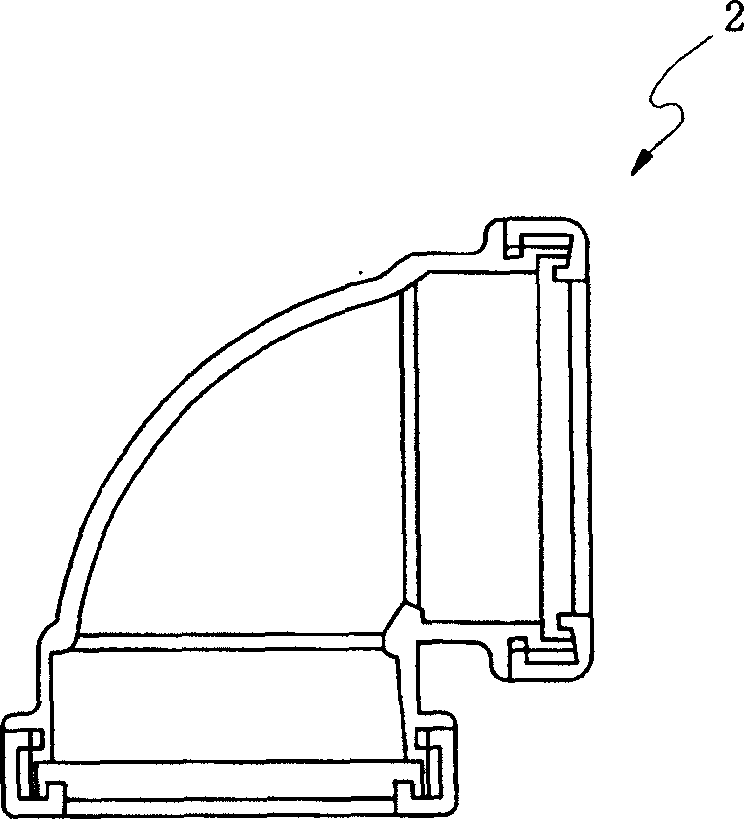

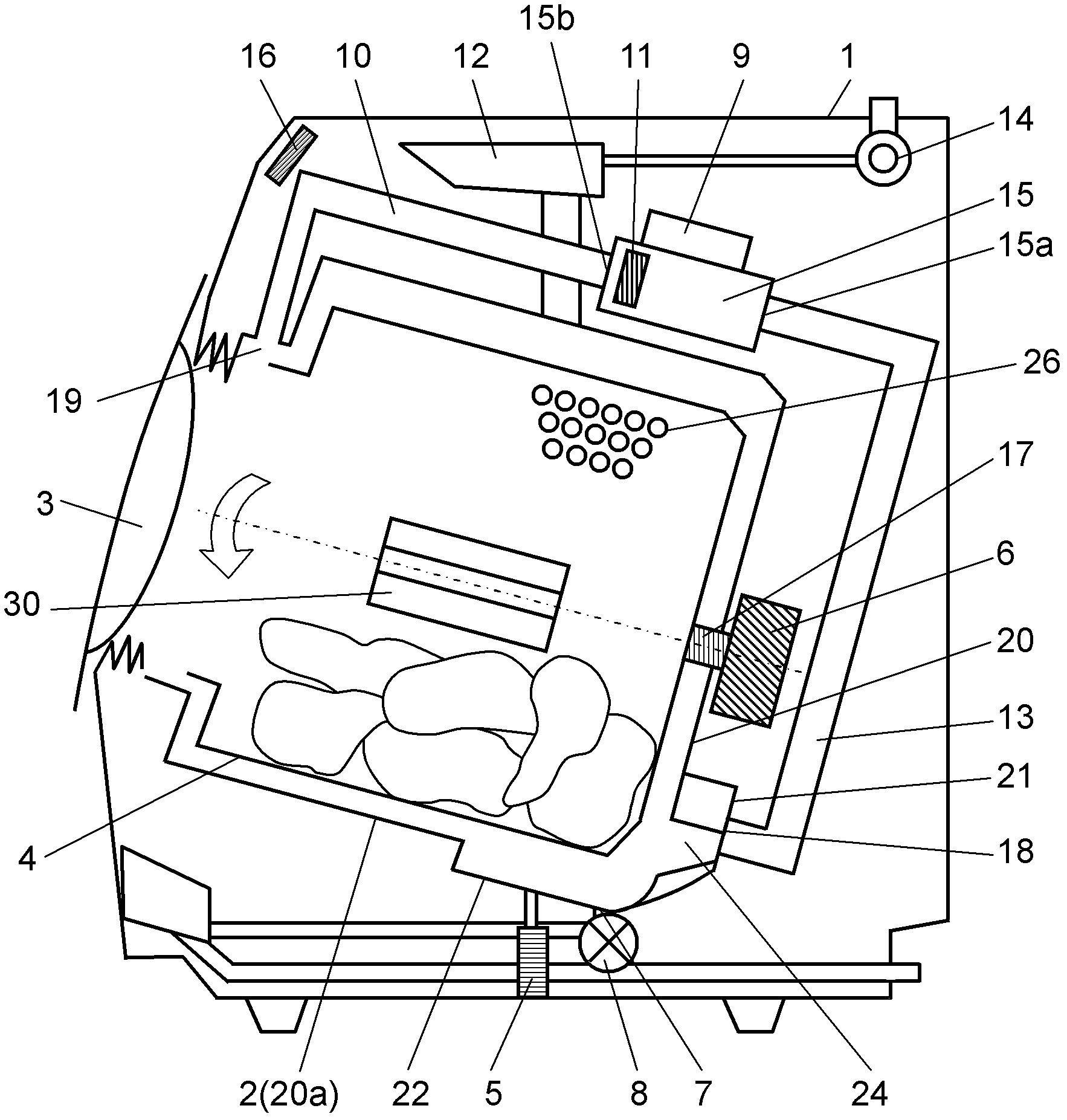

Low-noise groove diversion type vortex joint

ActiveCN104390084AImprove hydraulic conditionsReduce positive and negative pressure fluctuationsPipe elementsBranching pipesLow noisePipe water

The invention discloses a low-noise groove diversion type vortex joint. The low-noise groove diversion type vortex joint comprises an upper body, a main body and a lower body, wherein the upper body and the main body are connected through a thread; the upper body and the lower body are combined to a vertical pipe water flowing channel; a transverse pipe water flowing channel is formed in the main body; a transverse pipe lateral water inlet baffle plate is arranged at one side of the transverse pipe water flowing channel; a main body water inlet is formed in the other side of the transverse pipe water flowing channel; the main body and the lower body are connected through a thread; a conical transition section is arranged at the lower part of the lower body; and a lower body water outlet is formed in the lower part of the conical transition section. The low-noise groove diversion type vortex joint has the advantages of high drainage flow, low drainage noise, saving of building area, reduction of comprehensive cost, energy conservation and environmental protection.

Owner:浙江中财管道科技股份有限公司

High temperature mute drainpipe

The invention discloses a high temperature mute drainpipe, tubing raw materials of which comprise the followings, by weight: 25-30% of PP-B, 5-10% of high-molecular elastomer, 55-60% of barium sulfate, 1-3% of coupling agent, 0.3-0.8% of paraffin, 0.2-1.0% of stearate, 0.1-0.5% of white oil, and 0.5-1.0% of processing auxiliary agent. All the raw materials are mixed and extruded by a double-screwextruder to obtain the high temperature mute drainpipe. The high temperature mute drainpipe of the present invention has a density larger than 1400kg / m<3>, a vertical retraction rate of 0.47% and a Vicat softening temperature higher than 140DEG C. In an indoor equipressure contrast test with a same drainage device, a cast iron pipe, a PVC solid wall tube, a PVC hollow spiral pipe and the high temperature mute drainpipe of the present invention are used. And the high temperature mute drainpipe of the present invention is superior to the cast iron pipe, the PVC solid wall tube and the PVC hollow spiral pipe.

Owner:上海深海宏添建材有限公司

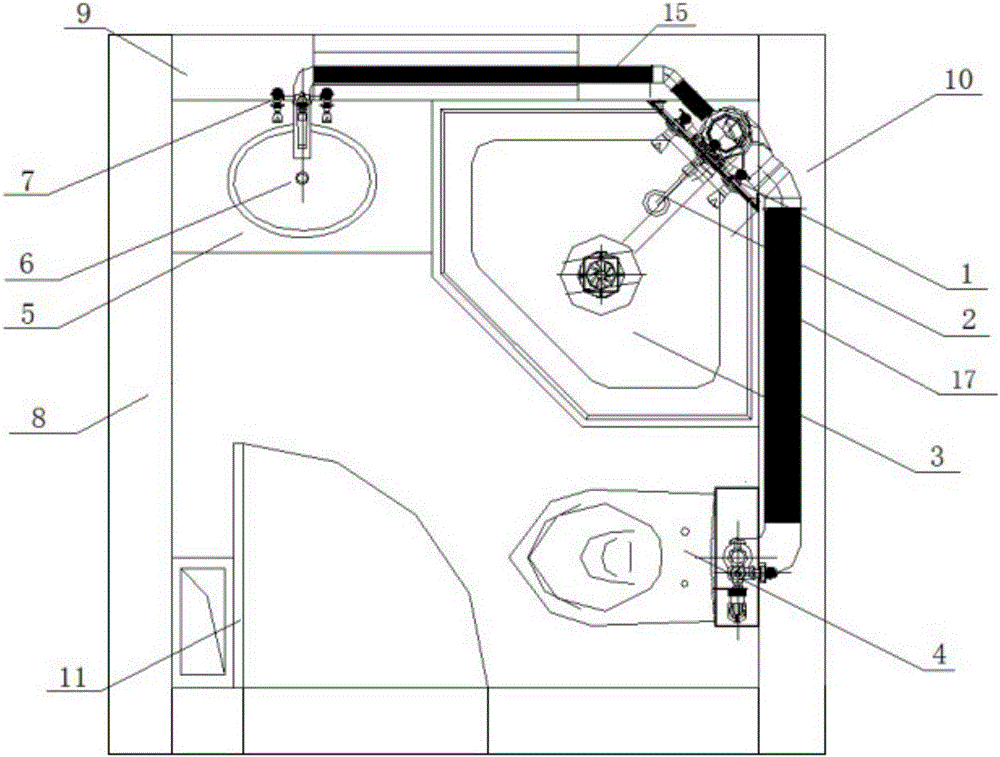

Assembled bathroom and construction method for same

InactiveCN106049903AMeet construction requirementsLoad-bearingDomestic plumbingSpecial buildingLine tubingBathroom Equipment

The invention relates to an assembled bathroom and a construction method for the same. The bathroom comprises a floor, four wall bodies, a ceiling and bathroom equipment. According to the invention, the floor and the wall bodies have triple functions including entity existence, decoration and waterproof performance; floor drains, horizontal-row pipelines and vertical-pipe socket-and-spigot joints are disposed in the floor; and water supply and drainage pipelines, electric appliance circuits, installation parts of sanitary ware and the like are disposed in the wall bodies. The assembled bathroom provided by the invention is characterized in that the floor and the wall bodies are different from a floor and wall bodies of a traditional box-type bathroom, integrate functions of structure, decoration, waterproof performance, pipelines and the like, and are capable of load bearing, sound insulation and division; each whole-face wall body is prefabricated and integrated at a factory; only the four wall bodies need to be assembled on site; and requirements of construction structure systems such as modern PC structures and steel structures can be satisfied. Meanwhile, a brand-new drainage system is adopted in the floor, so that floor descending is not needed during same-layer drainage, and the drainage system has advantages which cannot be prevailed by a same-layer floor-descending drainage mode.

Owner:焦明先

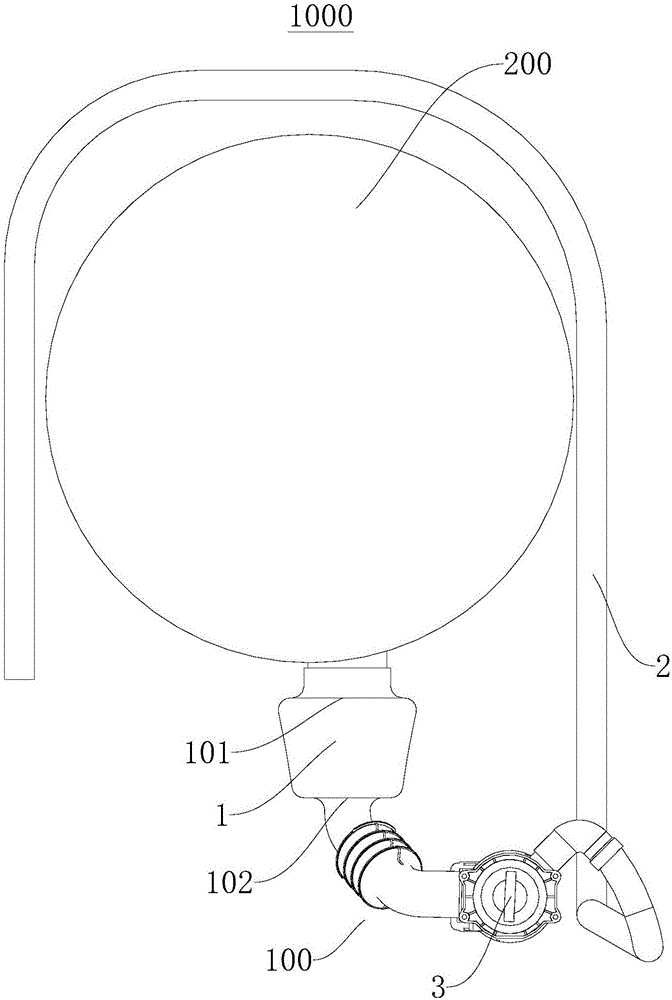

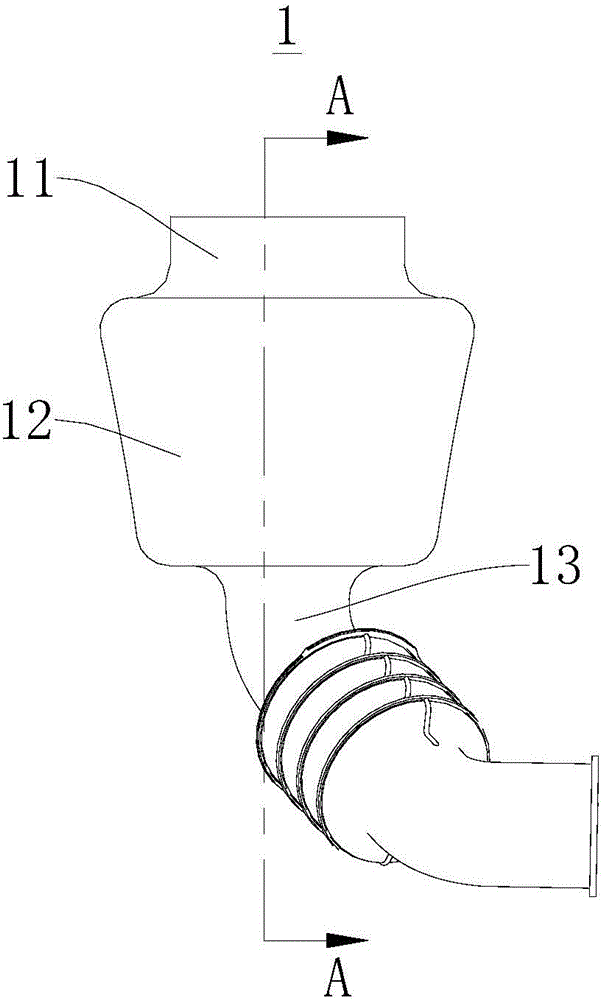

Clothes dryer and drainage system thereof

ActiveCN105839370AGood drainageReduce drainage noiseTextiles and paperLaundry driersDraining tubeEngineering

The invention discloses a drainage system of a clothes dryer and the clothes dryer with the drainage system. The drainage system comprises a condensate water container, a drainage pump, a drainage pipe and a water accumulation container. A condensate water cavity is defined in the condensate water container and provided with a condensate water inlet communicated with a condensate water outlet of the clothes dryer. One end of the drainage pump is connected with the condensate water container. A drainage opening is formed in one end of the drainage pipe. The water accumulation container is connected between the other end of the drainage pump and the other end of the drainage pipe. In the vertical direction, the highest point of an outlet of the water accumulation container is lower than the lowest point of an inlet of the water accumulation container and one part of the drainage pipe, and the lowest point of the outlet is not higher than the drainage pipe. According to the drainage system in the embodiment, condensate water is easy to drain, the drainage performance is good, and the drainage noise is low.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

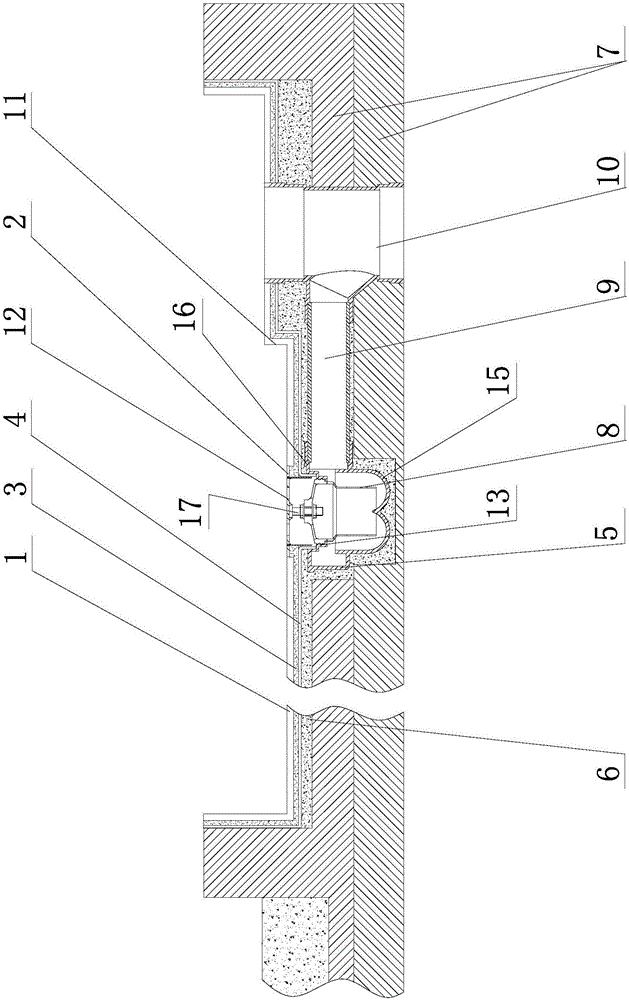

Drainage riser connector of caisson-type toilet

InactiveCN103938679ASolve the secondary drainage problemReasonable designDomestic plumbingEngineeringMechanical engineering

The invention discloses a drainage riser connector of a caisson-type toilet. The drainage riser connector comprises a riser connecting pipe, wherein a lead-in pipe connecting opening is formed in the upper part of the riser connecting pipe; a lead-out pipe connecting opening is formed in the lower part of the riser connecting pipe; the riser connecting pipe is of a structure with an annular waist base extending outwards around the middle section and an annular waist leakage liquid lead-in channel formed on the annular waist base; the annular waist leakage liquid lead-in channel comprises an annular waist leakage liquid collection opening formed in the top surface of the annular waist base, an annular waist leakage liquid lead-in opening which introduced into the riser connecting pipe from the lower part of the annular waist leakage liquid collection opening, and an annular waist leakage liquid diversion cavity connected between the annular waist leakage liquid collection opening and the annular waist leakage liquid lead-in opening; the riser connecting pipe is provided with a diversion baffle for preventing down water from flowing backward into the annular waist leakage liquid lead-in opening in the inner wall corresponding to the position above the annular waist leakage liquid lead-in opening. Compared with the prior art, the secondary drainage problems of drainage caissons at the same layer can be thoroughly solved.

Owner:ZHEJIANG SANLENG PLASTIC

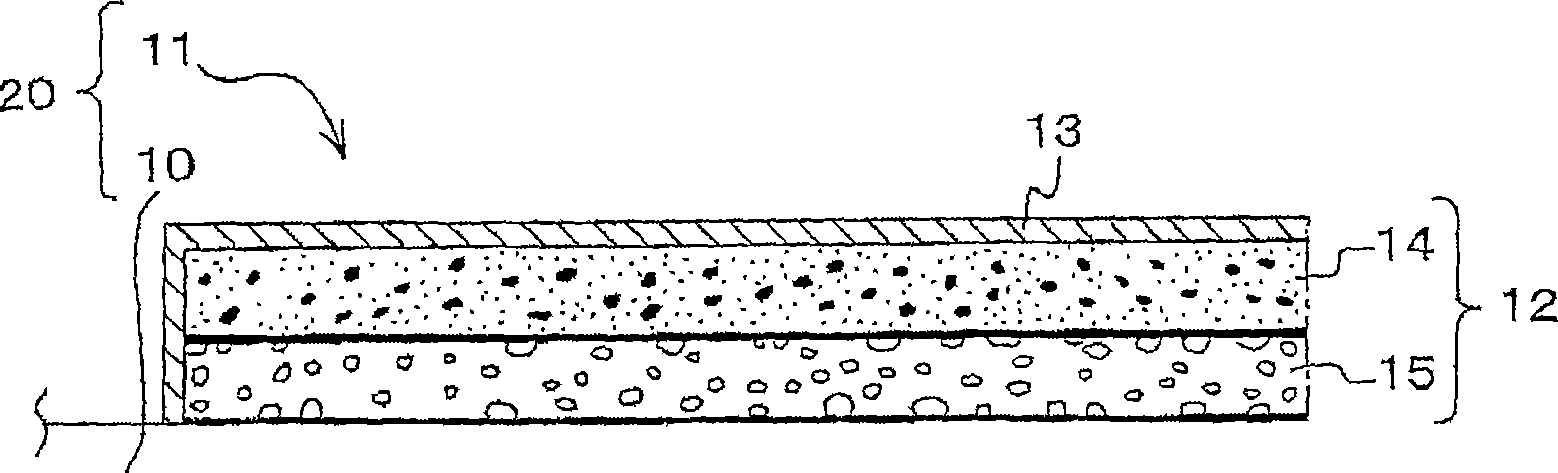

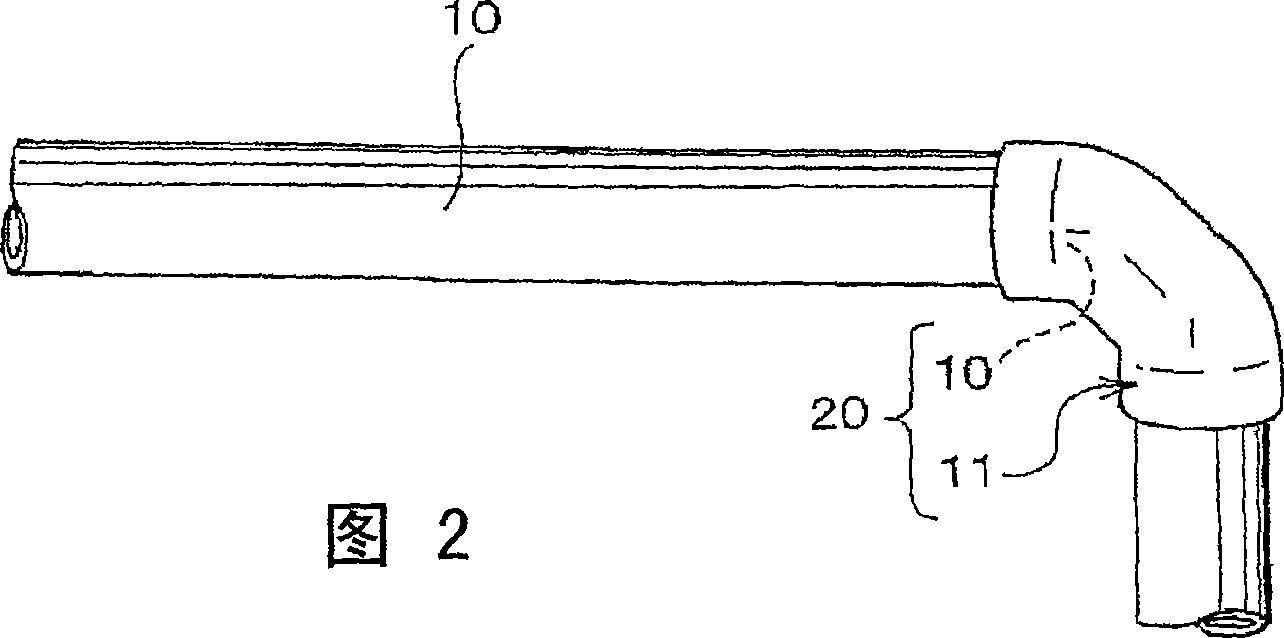

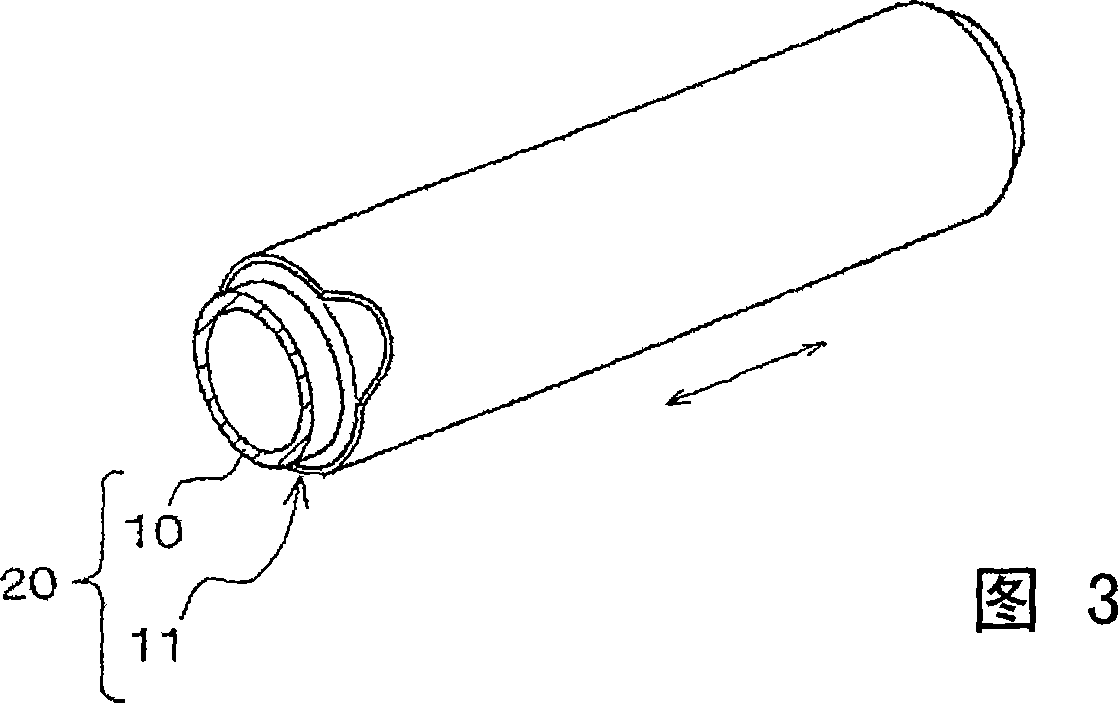

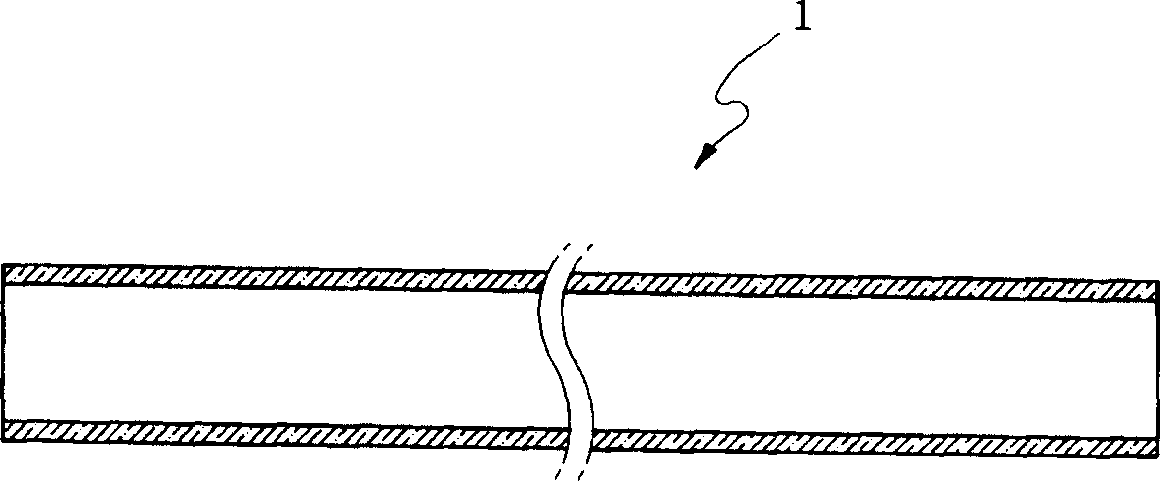

Soundproof coating material and soundproof drain pipe

It provides a soundproof coating material and a soundproof drain pipe. The soundproof coating material comprises a soundproof layer coated on the outer periphery of a pipe having a sound insulating outer layer with an elastic modulus of 1.0 10<6> to 3.0 10<6>Pa and a sound absorbing inner layer with an elastic modulus of 0.5 10<3> to 2.0 10<3>Pa so that the soundproof layer can be securely and smoothly mounted on the outer periphery of the pipe. Accordingly, in the soundproof drain pipe thus obtained, the soundproof layer is allowed to slide on the outer periphery of the pipe and the soundproof layer is prevented from being fallen off from the outer periphery of the pipe. As a result, the handling of the soundproof drain pipe can be improved and supply / drain noise therefrom can be effectively reduced.

Owner:SHISHIAI KK

Closestool blowdown structure and closestool

The invention provides a closestool blowdown structure. The closestool blowdown structure comprises a buffer chamber, an on-off valve and a control mechanism used for driving the on-off valve to be switched between a water seal state and a drainage state. A water inlet of the temporary storage chamber is communicated with a closestool blow-off pipe, and a water outlet of the temporary storage chamber is communicated with a blow-off sewer pipe; the on-off valve is arranged at the water outlet of the buffer chamber and located in the buffer chamber; a first liquid level sensor is arranged in the buffer chamber, when the closestool flushes water, the liquid level in the buffer chamber rises, and when the first liquid level sensor detects a liquid level signal, the control mechanism controls the on-off valve to be switched to a drainage state; and the position of the first liquid level sensor is higher than the water sealing surface when water is not flushed. The invention further provides a closestool, the closestool drainage structure is used, the pipe diameter of the drainage pipe can be increased, an S-shaped bent pipe is omitted, drainage resistance is reduced, and drainage noise is reduced.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

High-temperature silencing drainage pipe

The invention discloses a high-temperature silencing drainage pipe which is composed of the following raw materials in percentage by mass: the invention discloses a high-temperature silencing drainage pipe which is composed of the following raw materials in percentage by mass: 80-100 parts of polyester fiber, 50-80 parts of polystyrene, 8-10 parts of polycarbonate, 5-8 parts of polyethylene, 3-5 parts of polyvinyl chloride, 2-3 parts of polyethylene terephthalate, 8-10 parts of aluminum sulfate, 5-10 parts of zinc sulfate, 8-10 parts of copper sulfate, 3-5 parts of rosin, 3-5 parts of asphalt, 5-6 parts of sodium alginate, 10-12 parts of polyethylene wax, 10-12 parts of glycerol and 10-12 parts of organic silicone oil. The high-temperature silencing drainage pipe has the advantages of simple structure, low manufacturing cost, favorable mechanical strength and favorable high temperature resistance, and can obviously lower the drainage noise.

Owner:周彩球

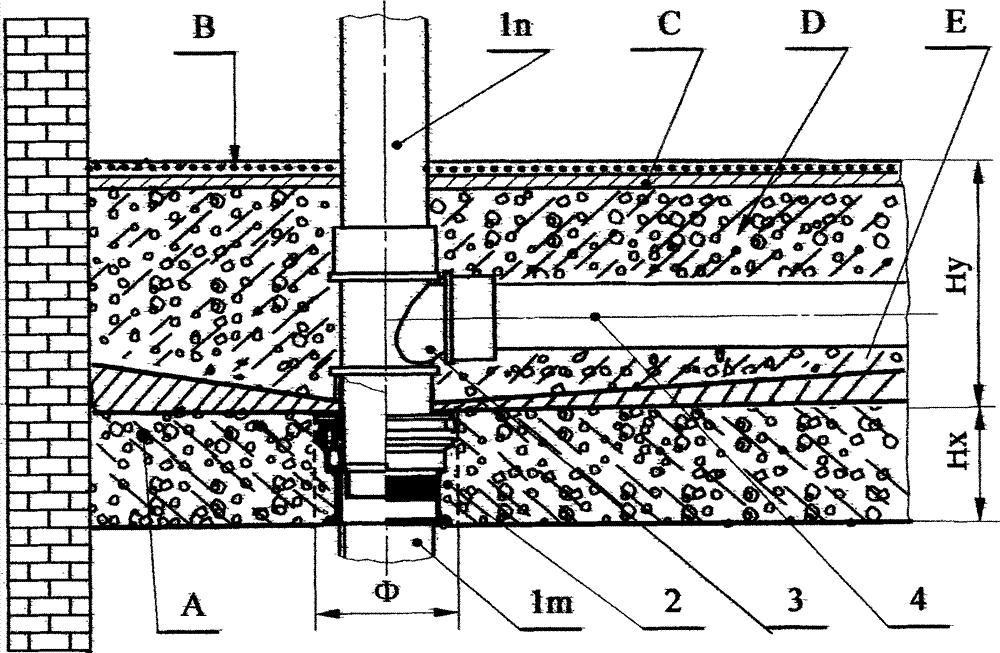

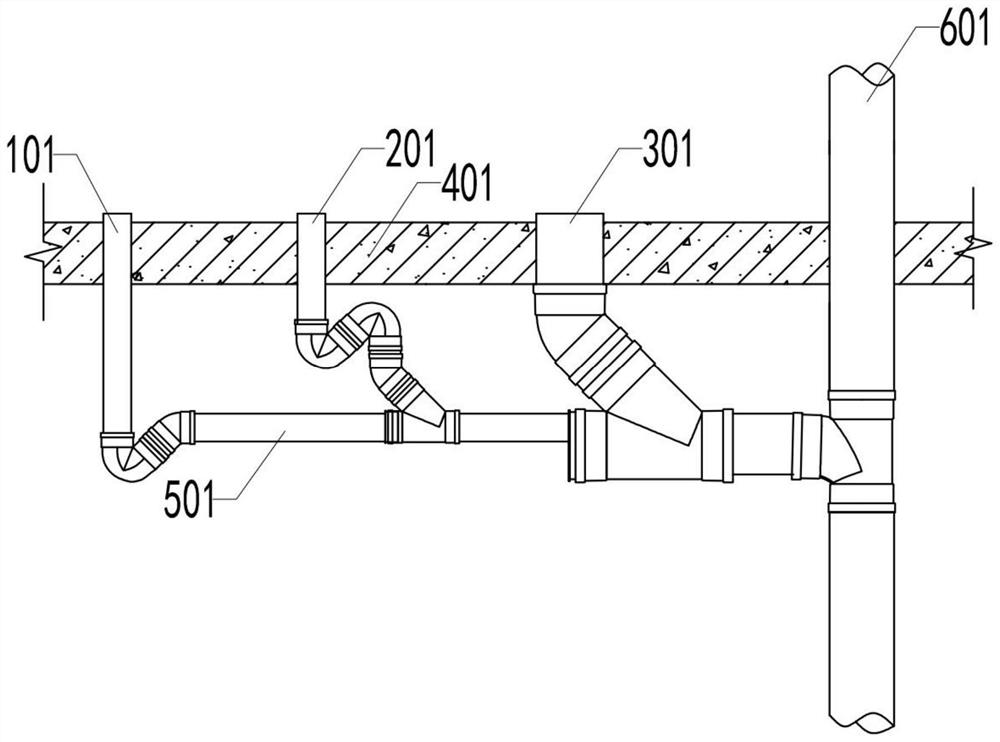

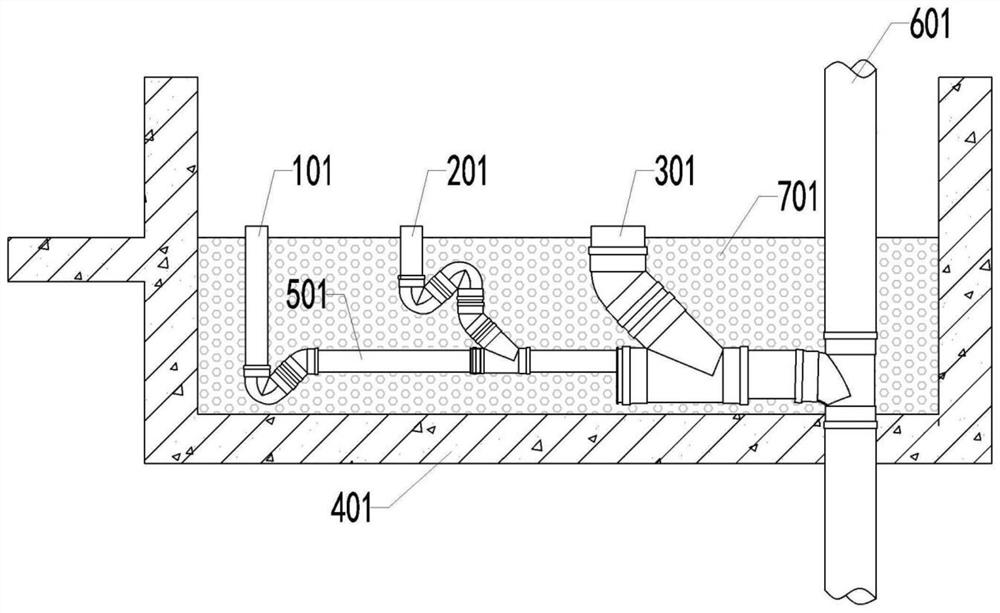

Assembled type bathroom floor slab and construction method

InactiveCN106013566ALow technical requirementsLess up and down interferenceSewerage structuresFloorsFloor slabSurface layer

The invention discloses an assembled type bathroom floor slab and a construction method. The assembled type bathroom floor slab is provided with an internally-arranged drainage system which comprises a vertical drainage pipe connector, a floor drain and a floor drain transverse drainage pipe; a drainage port of the floor drain is connected with the vertical drainage pipe connector through the floor drain transverse drainage pipe, and the bathroom floor slab is sequentially provided with a surface layer, a surface layer bonding layer, a waterproof layer and a structure layer from top to bottom. By adopting the scheme, the structure is reasonable, the cost is low, and an assembled type prefabricated bathroom can be manufactured on site or in advance; a reverse construction mode can be adopted, mechanized line production is achieved in construction, the technical requirements on constructors are low, and through simple treatment, the surface layer and the waterproof layer can achieve the very good effect; combined operation of a male formwork and an outer formwork is adopted, and therefore the construction speed and the construction quality are high; same-floor drainage is adopted, and therefore the advantages that construction is convenient, use is sanitary, the housing property is clear, little disturbance among floors is generated, and drainage noise is low are achieved.

Owner:孙续畅

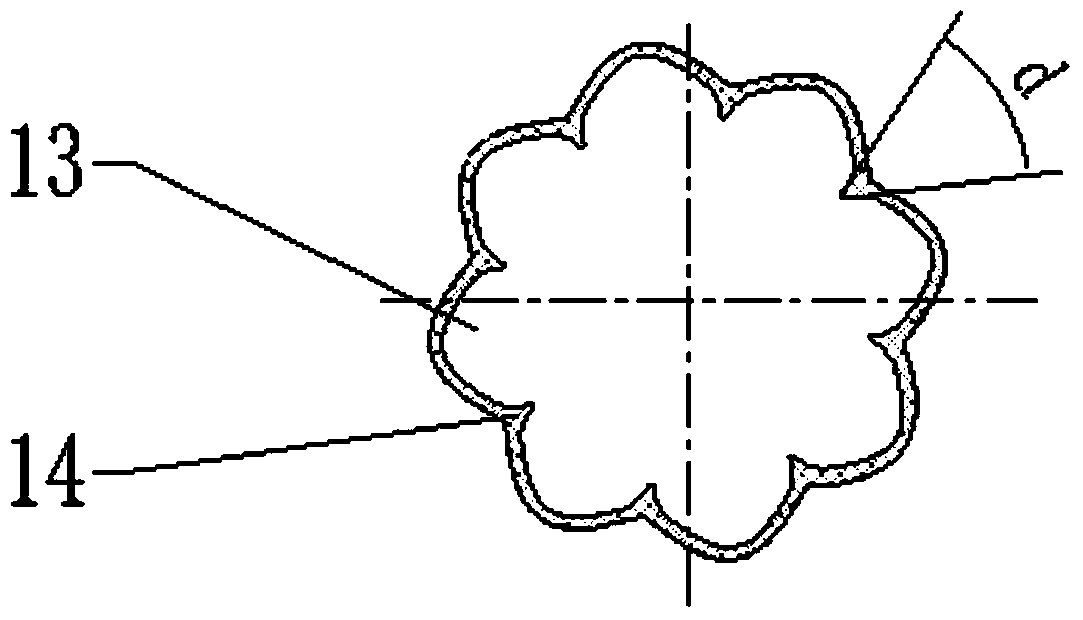

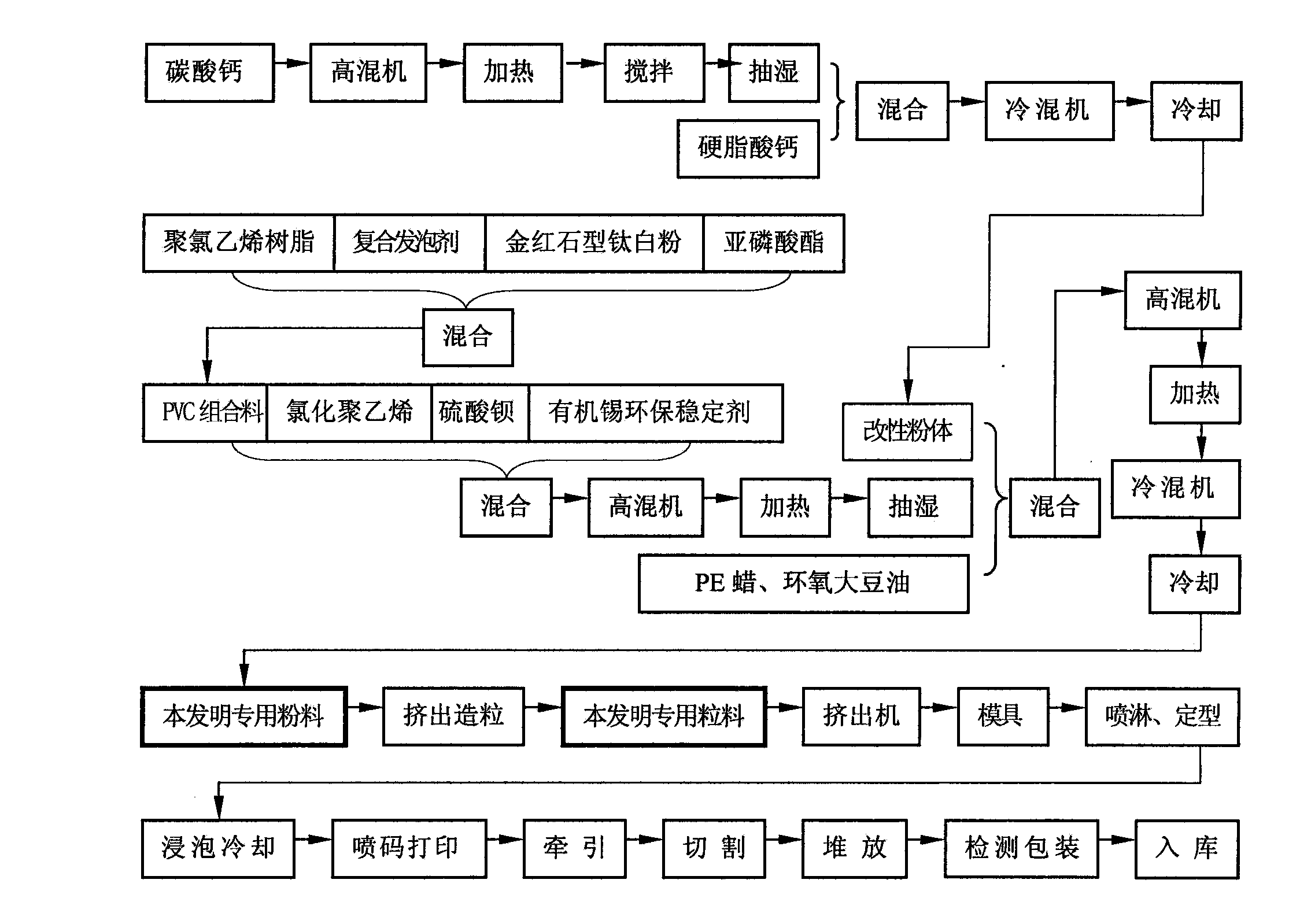

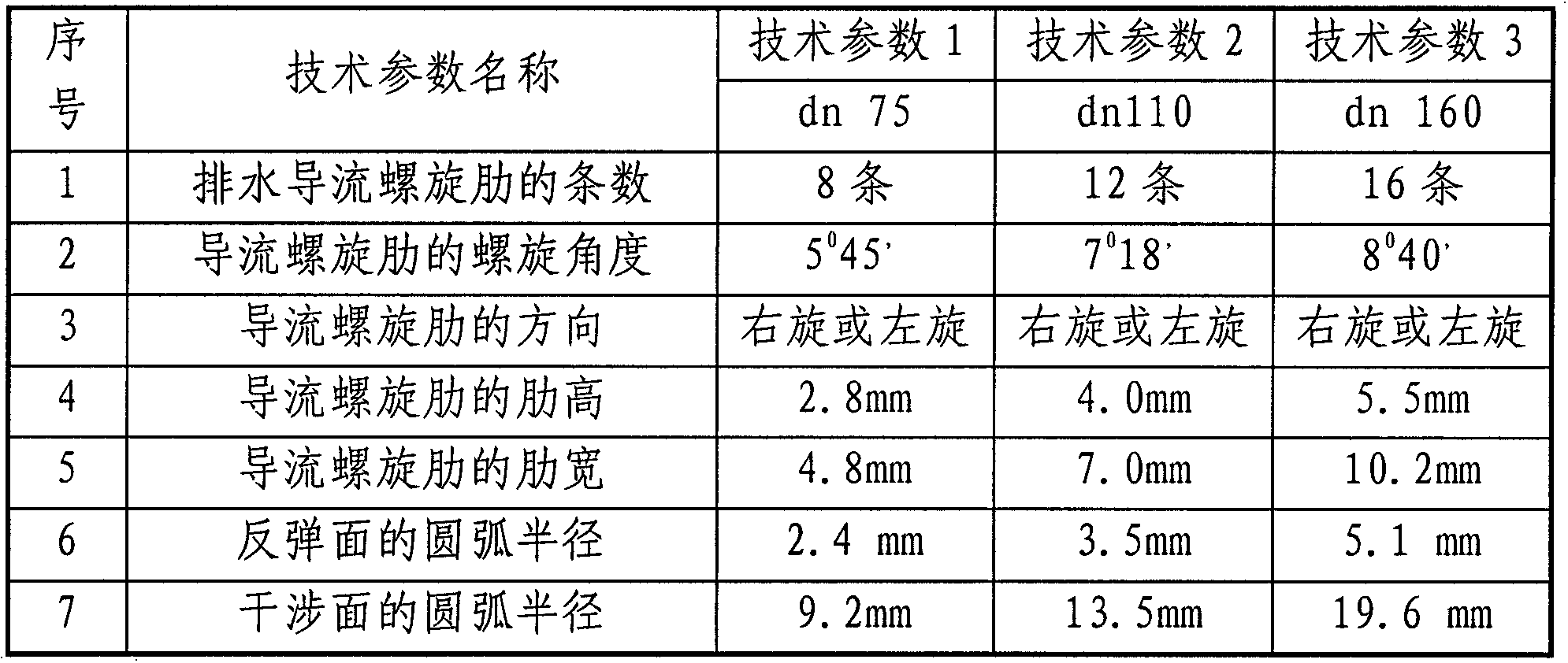

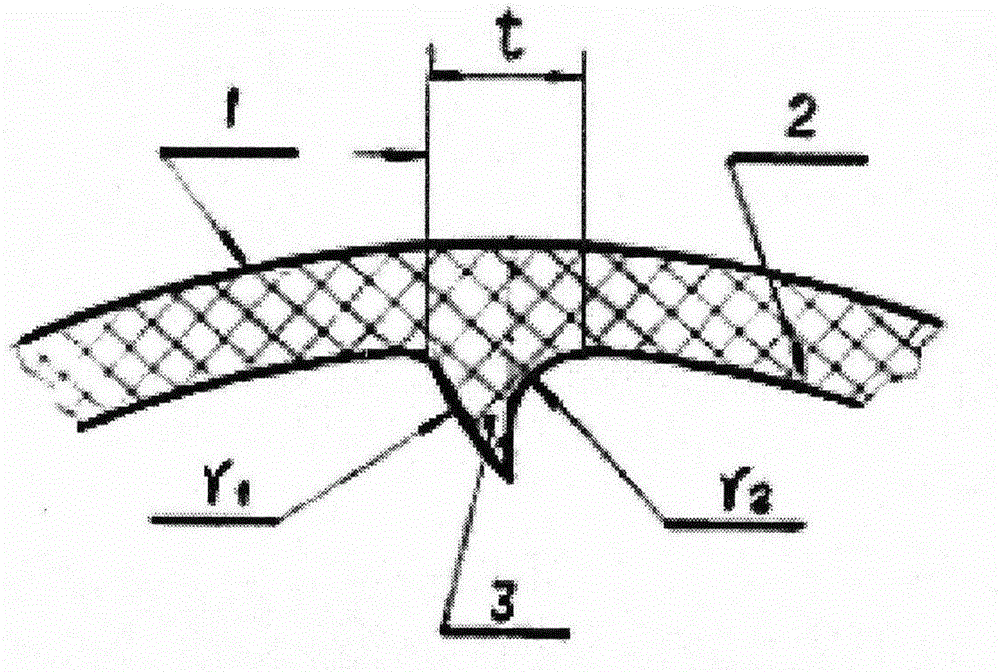

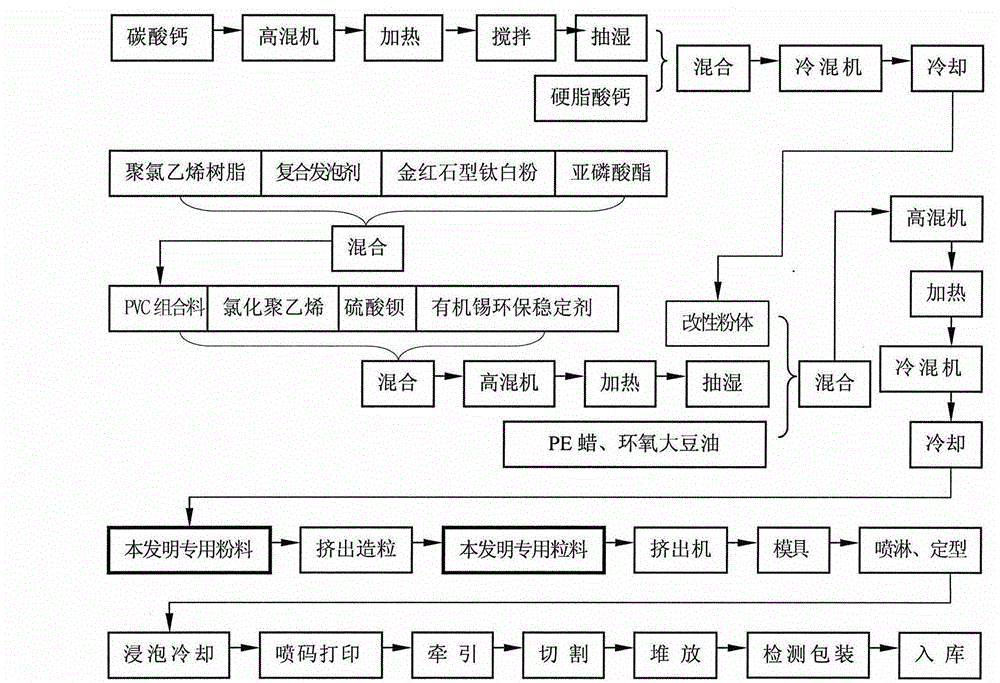

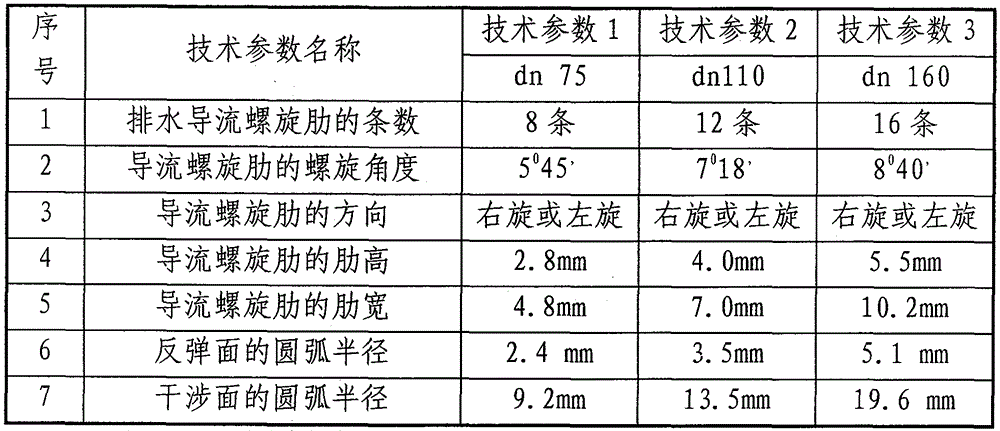

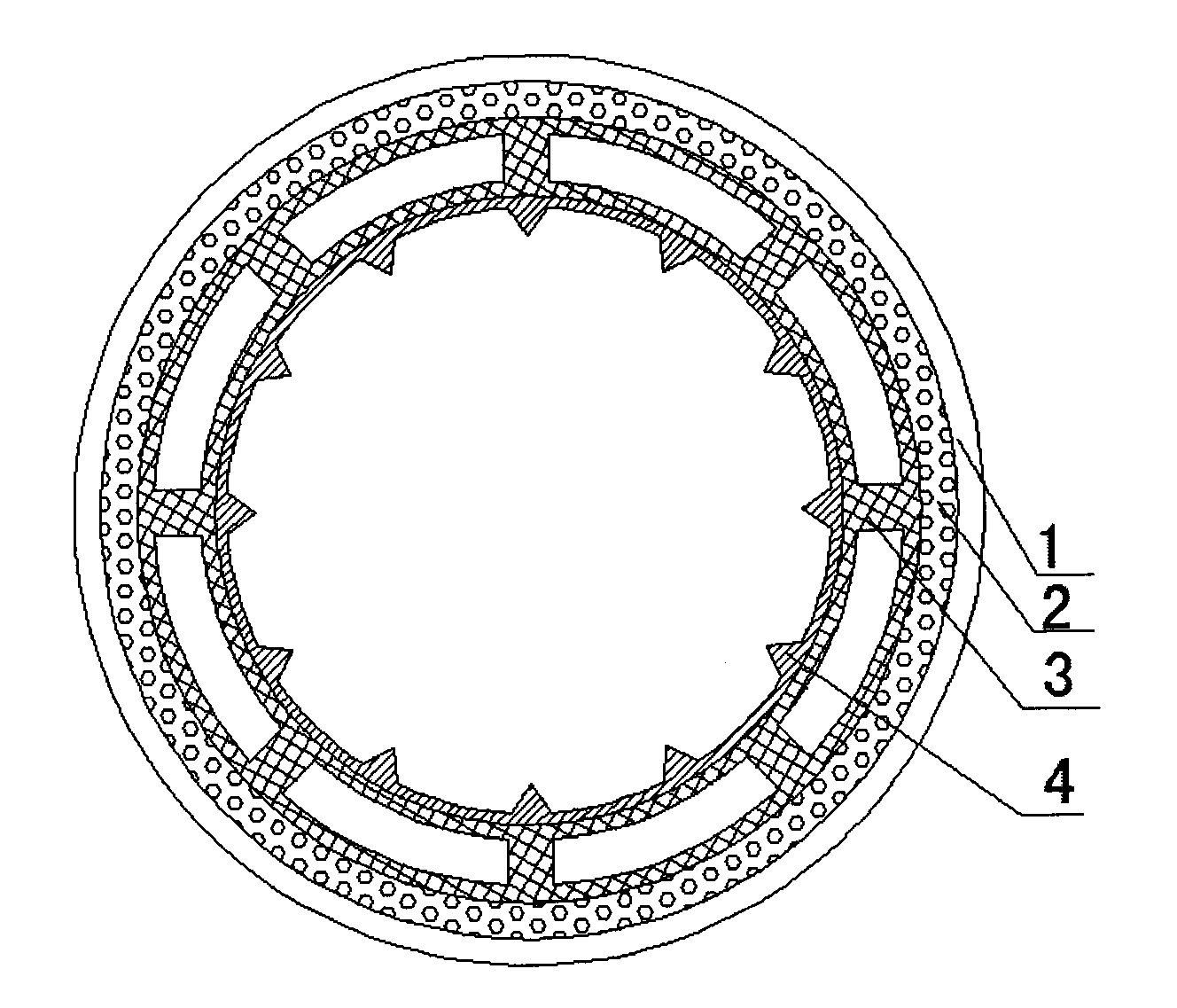

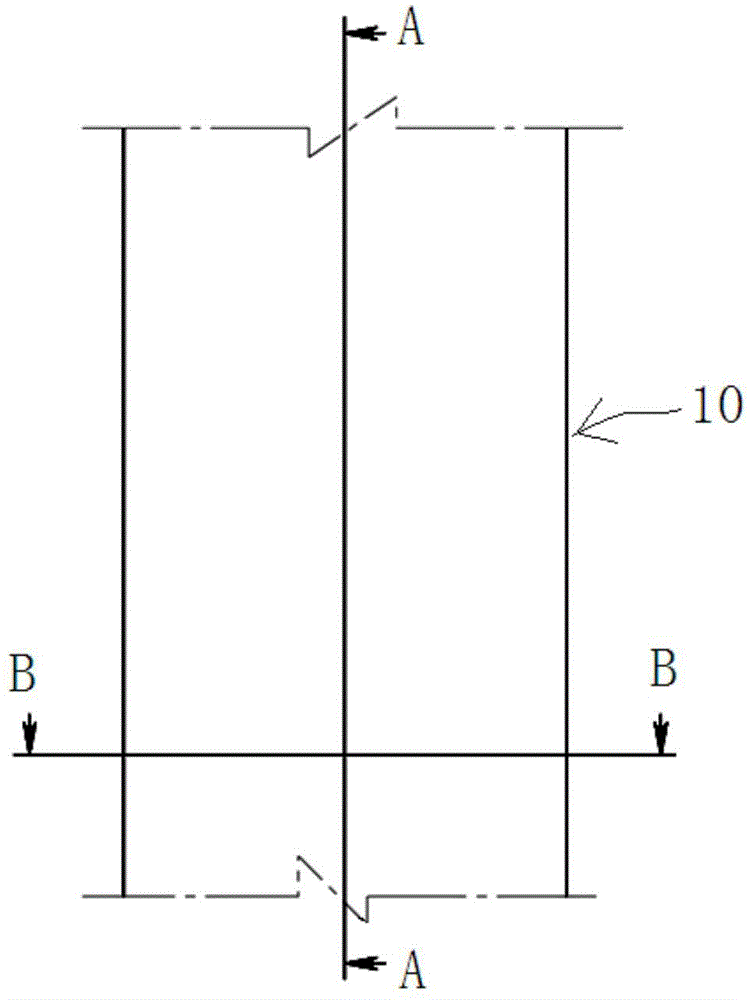

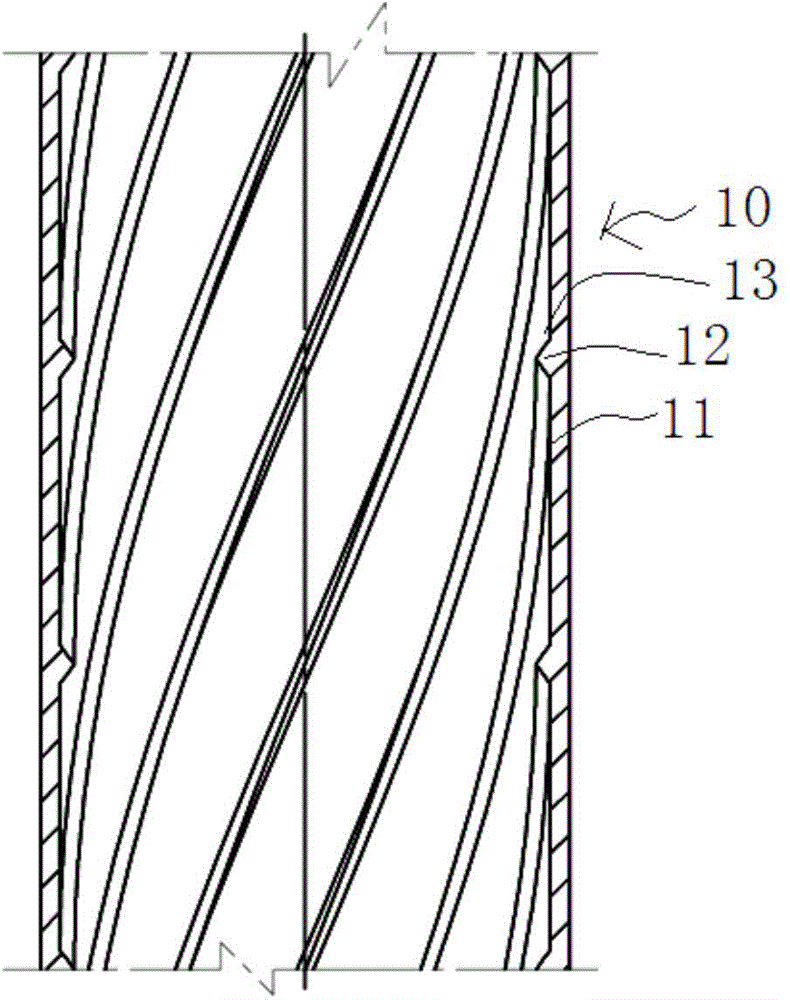

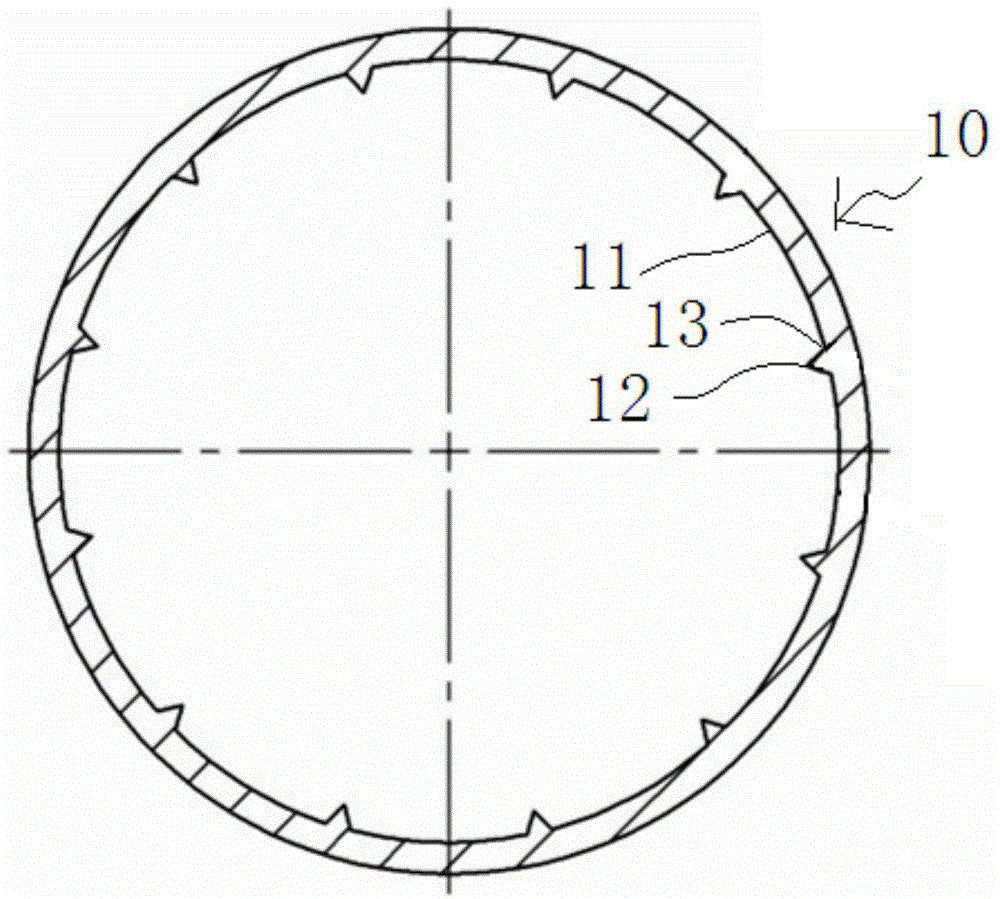

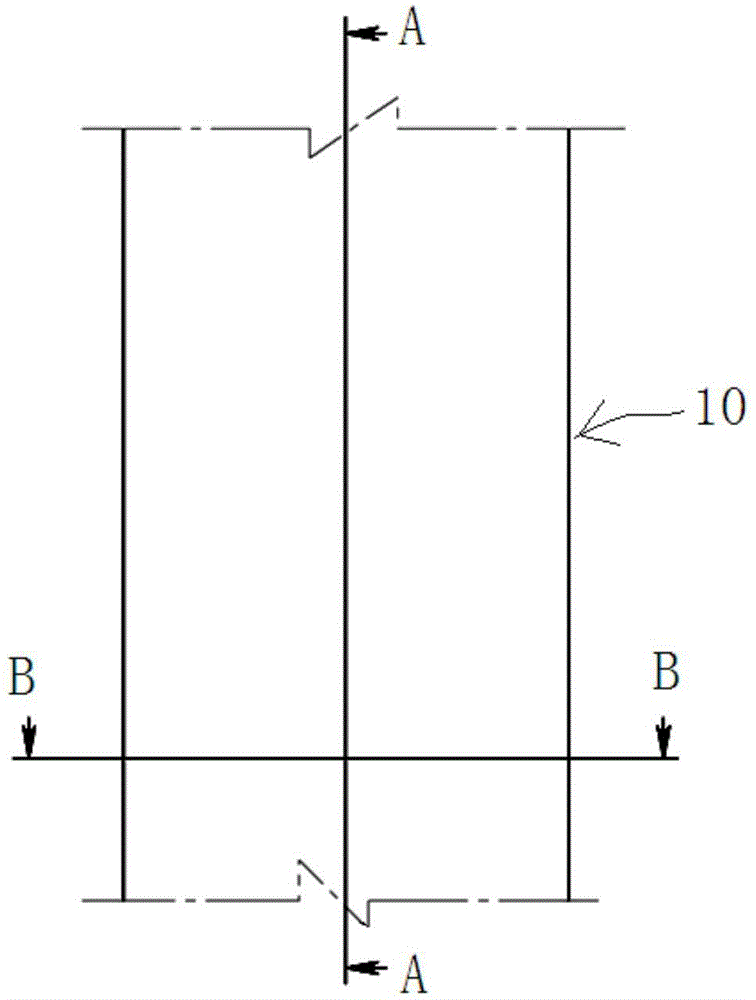

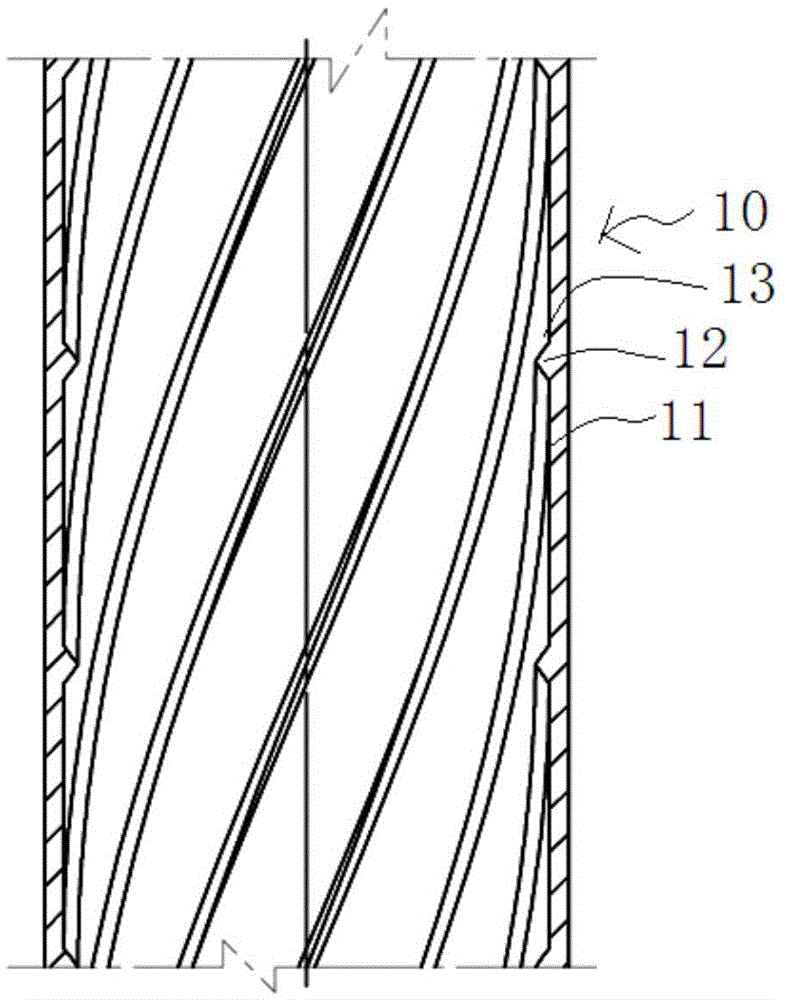

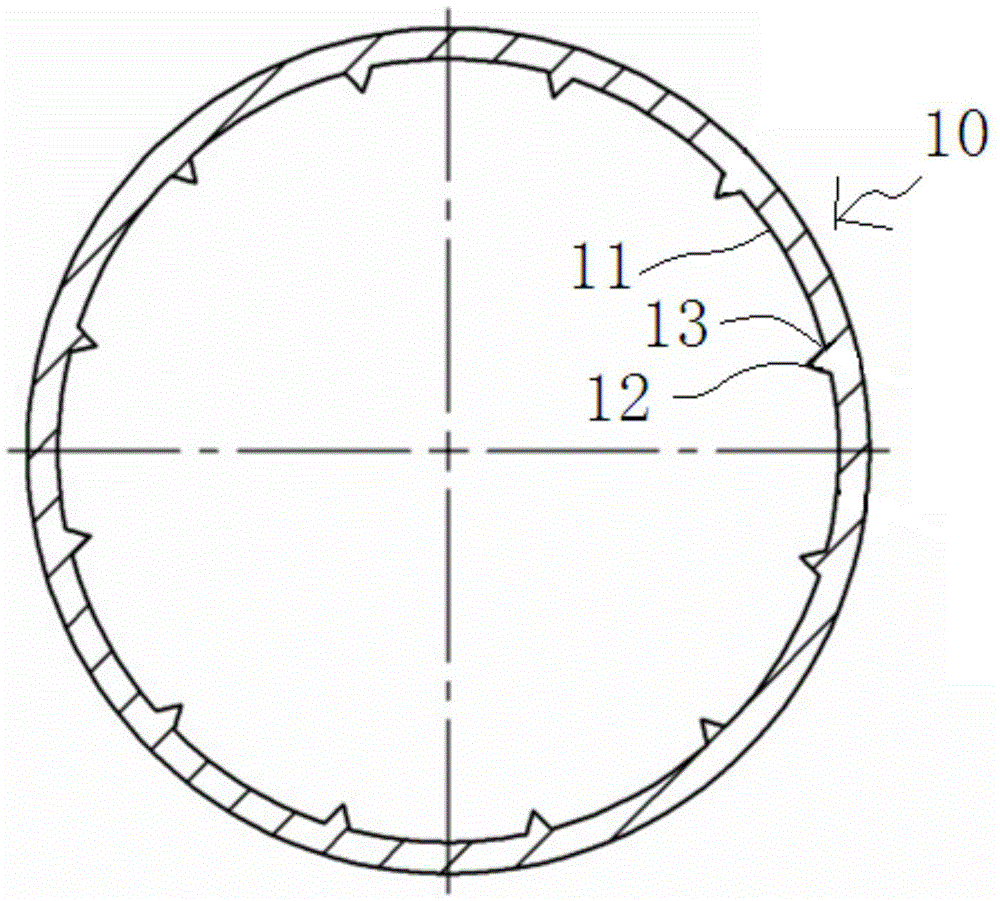

Vortex drainage-type noise reduction drainage pipe and manufacturing method thereof

ActiveCN103438291ASimple structureOptimize quantityRigid pipesManufacturing cost reductionEngineering

The invention discloses a vortex drainage-type noise reduction drainage pipe, which comprises a drainage pipe body. 6-18 guide spiral fins are connected with the inner wall of the drainage pipe body in a uniform distribution manner; each guide spiral fin is provided with a convex arc rebound surface and a concave arc interference surface; the spiral angle of each guide spiral fin is 3-12 degrees, and the spiral fins are 3-12mm wide, and 2-8.5mm high. The arc radius of each rebound surface is 3-12mm from the section view vertical to the normal cross section of the corresponding spiral fin; the arc radius of each interference surface is 7-22mm from the section view vertical to the normal cross section of the corresponding spiral fin. The invention also discloses a manufacturing method of the vortex drainage-type noise reduction drainage pipe. According to the vortex drainage-type noise reduction drainage pipe disclosed by the invention, the structure and the number of the internal spiral fins are optimized, and therefore, the drainage noise can be effectively reduced, and the strength of a drainage pipe material is enhanced. The vortex drainage-type noise reduction drainage pipe is widely suitable for building drainage pipelines of industrial or civil buildings, and is especially suitable for public communities with high noise reduction requirements. By adopting the method, the material prescription is optimized, and the manufacturing cost can be remarkably reduced.

Owner:ZHEJIANG SANLENG PLASTIC

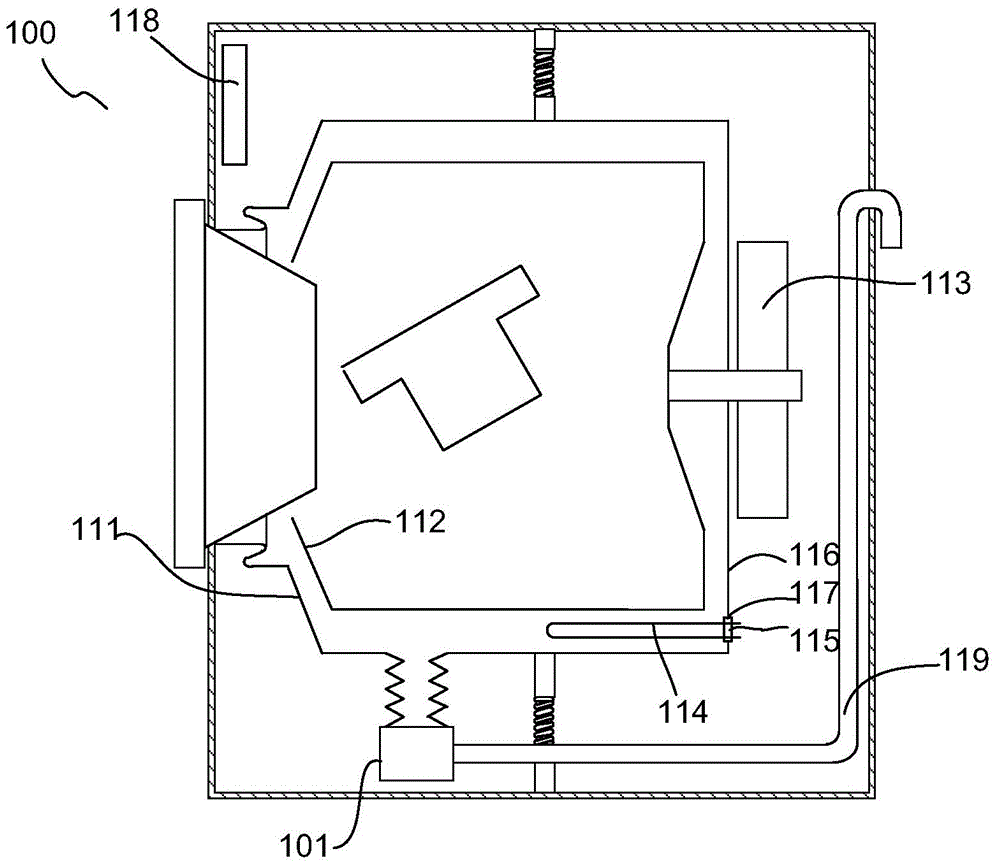

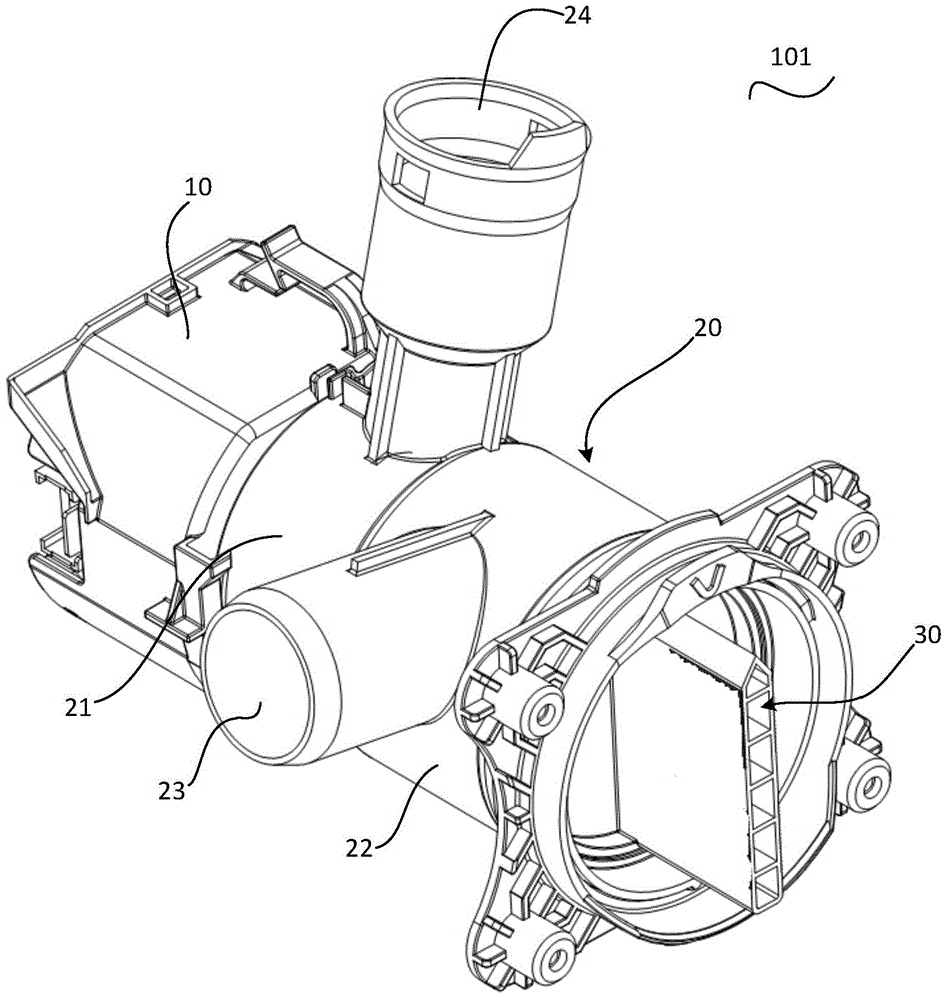

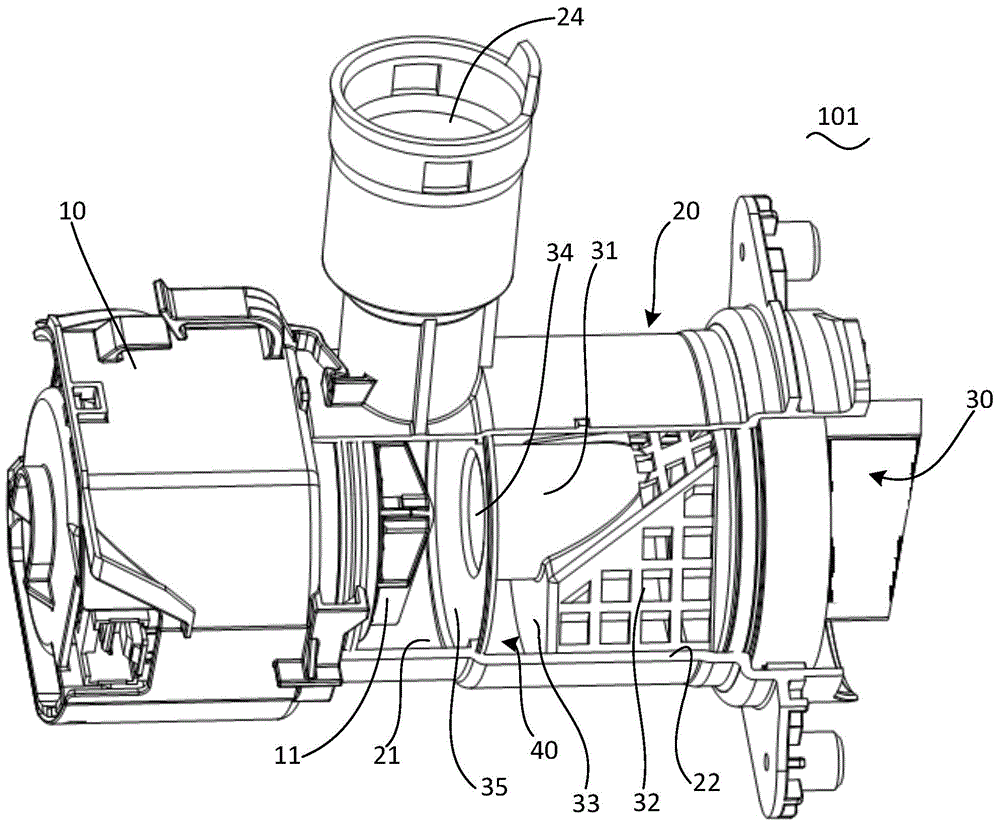

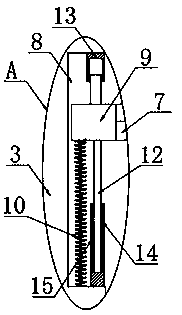

Drainage assembly for roller washing machine and roller washing machine with same

ActiveCN106436193AReduce drainage noiseImprove sound qualityOther washing machinesTextiles and paperEngineeringPulp and paper industry

The invention discloses a drainage assembly for a roller washing machine and a roller washing machine with the same. The drainage assembly comprises a first drainage pipe, a second drainage pipe, a drainage pump and a floating block. The inlet end of the first drainage pipe is connected with a roller. A valve cavity is defined inside the first drainage pipe. The valve cavity is provided with an upper inlet and a lower outlet. The outlet end of the second drainage pipe is communicated with the external world. The drainage pump is connected between the first drainage pipe and the second drainage pipe. The floating block is arranged inside the valve cavity. The minimum outer diameter of the floating block is larger than the minimum inner diameter of the lower outlet of the valve cavity, and the density of the floating block is smaller than that of water so that the floating block can fall down and seal the lower outlet of the valve cavity when the water level in the first drainage pipe is lower than a preset water level and can float upwards and open the lower outlet of the valve cavity when the water level of the first drainage pipe is higher than the preset water level, wherein the preset water level is higher than the pump cavity of the drainage pump. According to the drainage assembly, the drainage noise can be effectively lowered, and the sound quality can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Novel drainage pipe

The invention discloses a novel drainage pipe, in particular to the field of drainage pipes. The novel drainage pipe comprises a water inlet pipe, wherein an outer pipe is arranged at the bottom of the water inlet pipe, an inner pipe is arranged inside the outer pipe, the top of the water inlet pipe is arranged in an outward protrusion mode, a plurality of water permeable holes are formed in the top of the water inlet pipe in a penetrating mode, an arc plate is arranged on the inner surface of the water inlet pipe, and a water outlet is formed in the top of the water inlet pipe. According to the novel drainage pipe, impact force is exerted on an iron wire frame through water flow, the iron wire frame is moved downwards under the force, a clamping block moves downwards in a clamping groove,so that a spring is driven to be stressed and contracted, the water flow is buffered, the flow rate of the water is slowed down, so that a source of noise is reduced; meanwhile, a cavity formed through the inner pipe and the outer pipe is arranged in a vacuum mode, a sonic transmission channel is cut off, so that the noise is further reduced; and through a series of cooperation, the drainage noise of the drainage pipe can be reduced, and the comfort of people is improved.

Owner:邳州捷昌新材料有限公司

Manufacturing method of vortex water drainage type silencer drainage pipe

ActiveCN103438291BSimple structureOptimize quantityRigid pipesManufacturing cost reductionWater discharge

The invention discloses a vortex drainage-type noise reduction drainage pipe, which comprises a drainage pipe body. 6-18 guide spiral fins are connected with the inner wall of the drainage pipe body in a uniform distribution manner; each guide spiral fin is provided with a convex arc rebound surface and a concave arc interference surface; the spiral angle of each guide spiral fin is 3-12 degrees, and the spiral fins are 3-12mm wide, and 2-8.5mm high. The arc radius of each rebound surface is 3-12mm from the section view vertical to the normal cross section of the corresponding spiral fin; the arc radius of each interference surface is 7-22mm from the section view vertical to the normal cross section of the corresponding spiral fin. The invention also discloses a manufacturing method of the vortex drainage-type noise reduction drainage pipe. According to the vortex drainage-type noise reduction drainage pipe disclosed by the invention, the structure and the number of the internal spiral fins are optimized, and therefore, the drainage noise can be effectively reduced, and the strength of a drainage pipe material is enhanced. The vortex drainage-type noise reduction drainage pipe is widely suitable for building drainage pipelines of industrial or civil buildings, and is especially suitable for public communities with high noise reduction requirements. By adopting the method, the material prescription is optimized, and the manufacturing cost can be remarkably reduced.

Owner:ZHEJIANG SANLENG PLASTIC

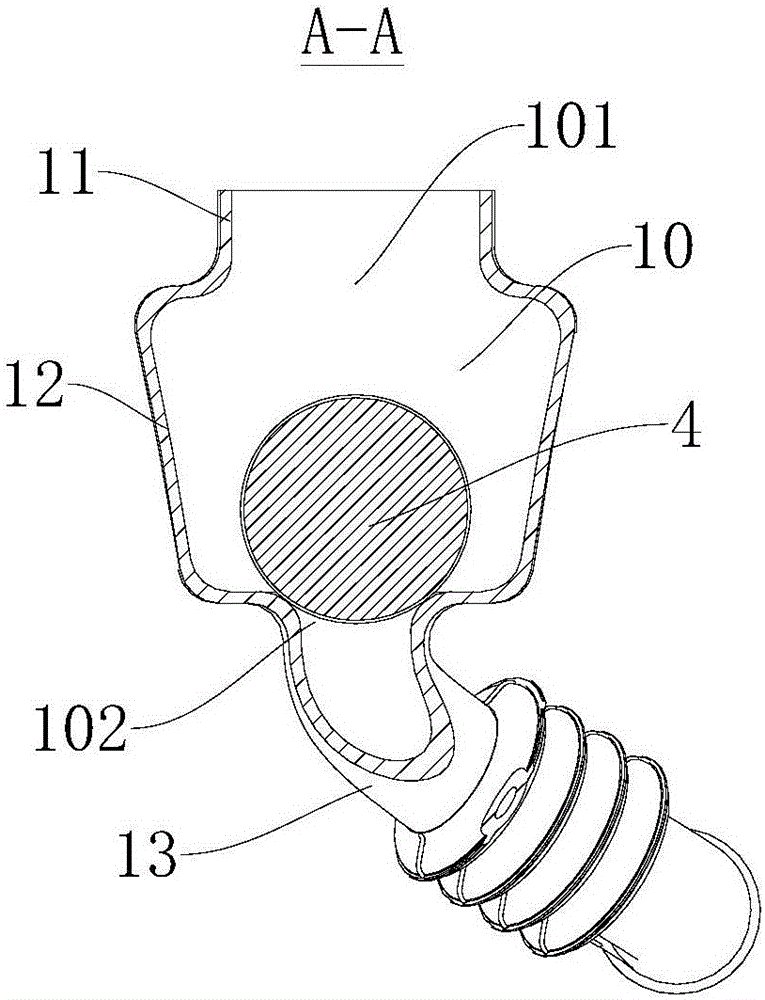

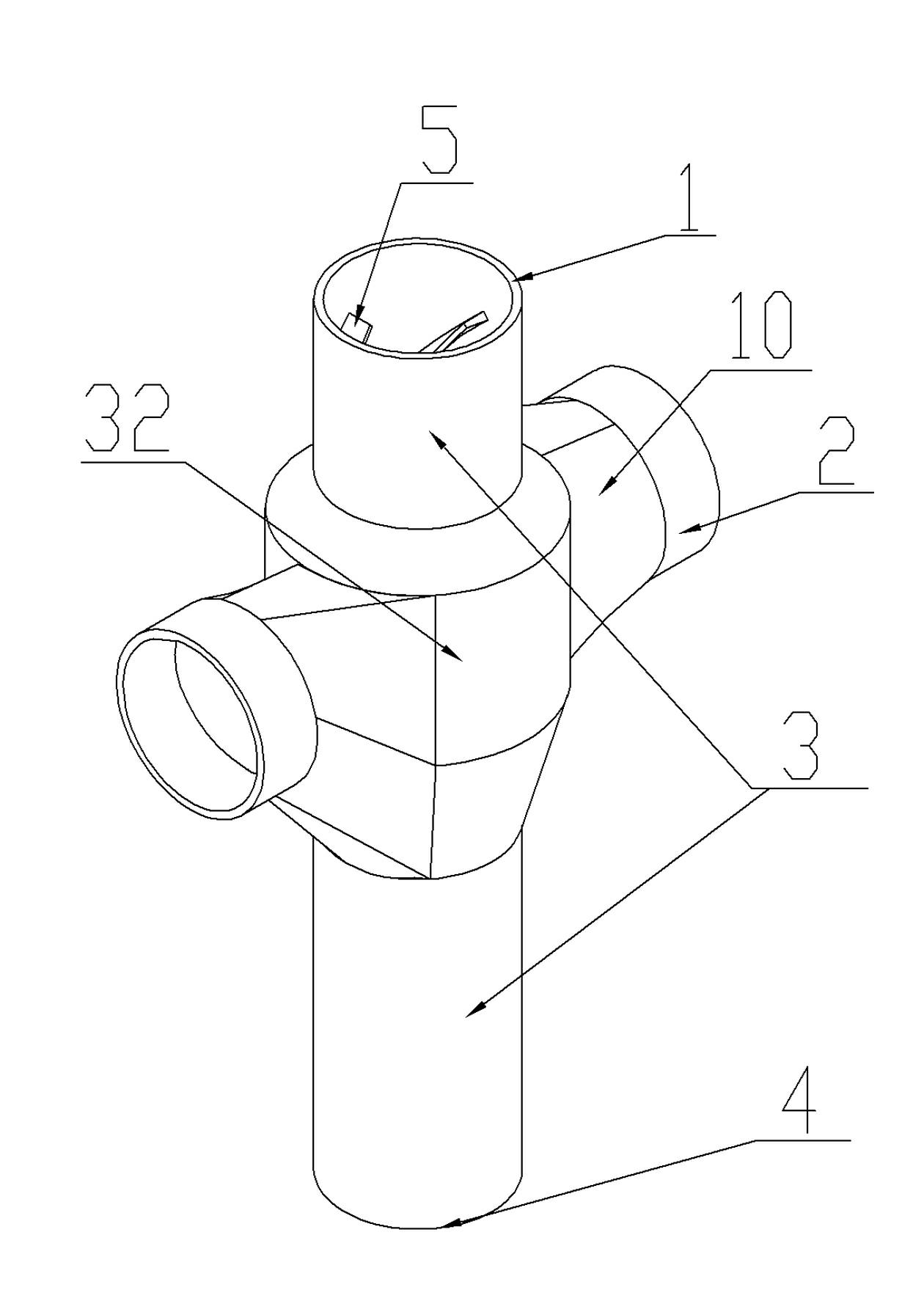

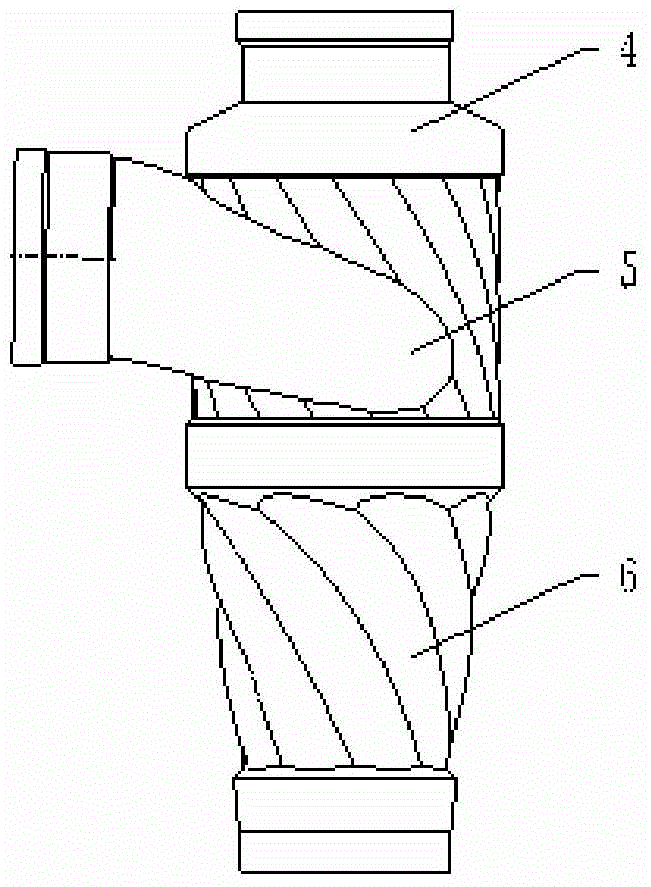

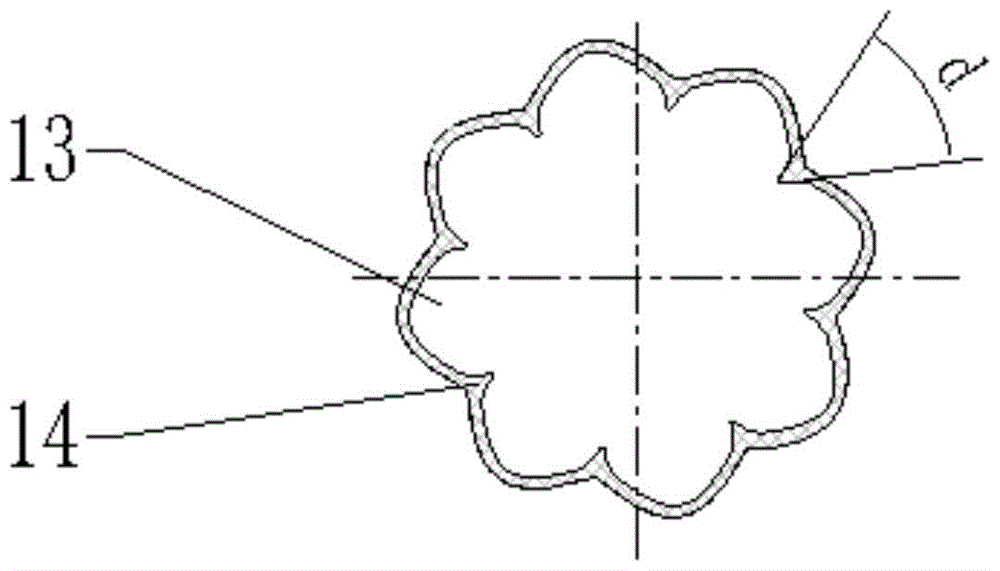

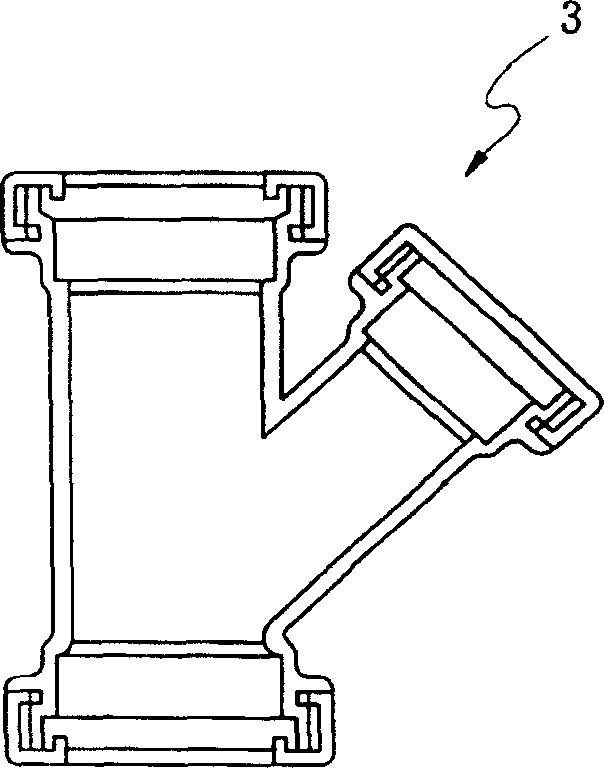

Joint of vortex drain tube

InactiveCN102095041AReduce the impact of water flowIncrease the cross-sectional areaBranching pipesVertical tubeInlet channel

The invention discloses a joint of a vortex drain tube, which comprises a vertical tube, wherein an upper water inlet is correspondingly arranged at the upper end of the vertical tube; a drain outlet is correspondingly arranged at the lower end of the vertical tube; spiral guide vanes which axially extend along the vertical tube are arranged between the upper water inlet and the drain outlet on the inner wall of the vertical tube; at least one side water inlet tube is arranged at the side of the vertical tube; a water outlet for communicating the side water inlet tube and a cavity at the middle part of the vertical tube is formed on a connecting part of the vertical tube and the side water inlet tube; a water inlet channel in the position of the water outlet of the side water inlet tube is communicated with the cavity at the middle part of the vertical tube along a tangential line; and the length of a cross section in the position of the water outlet of the connecting part of the side water inlet tube and the vertical tube along the axial direction of the vertical tube is larger than the length of a cross section in the position of the water inlet of the side water inlet tube along the axial direction of the vertical tube.

Owner:禹州市新光铸造有限公司

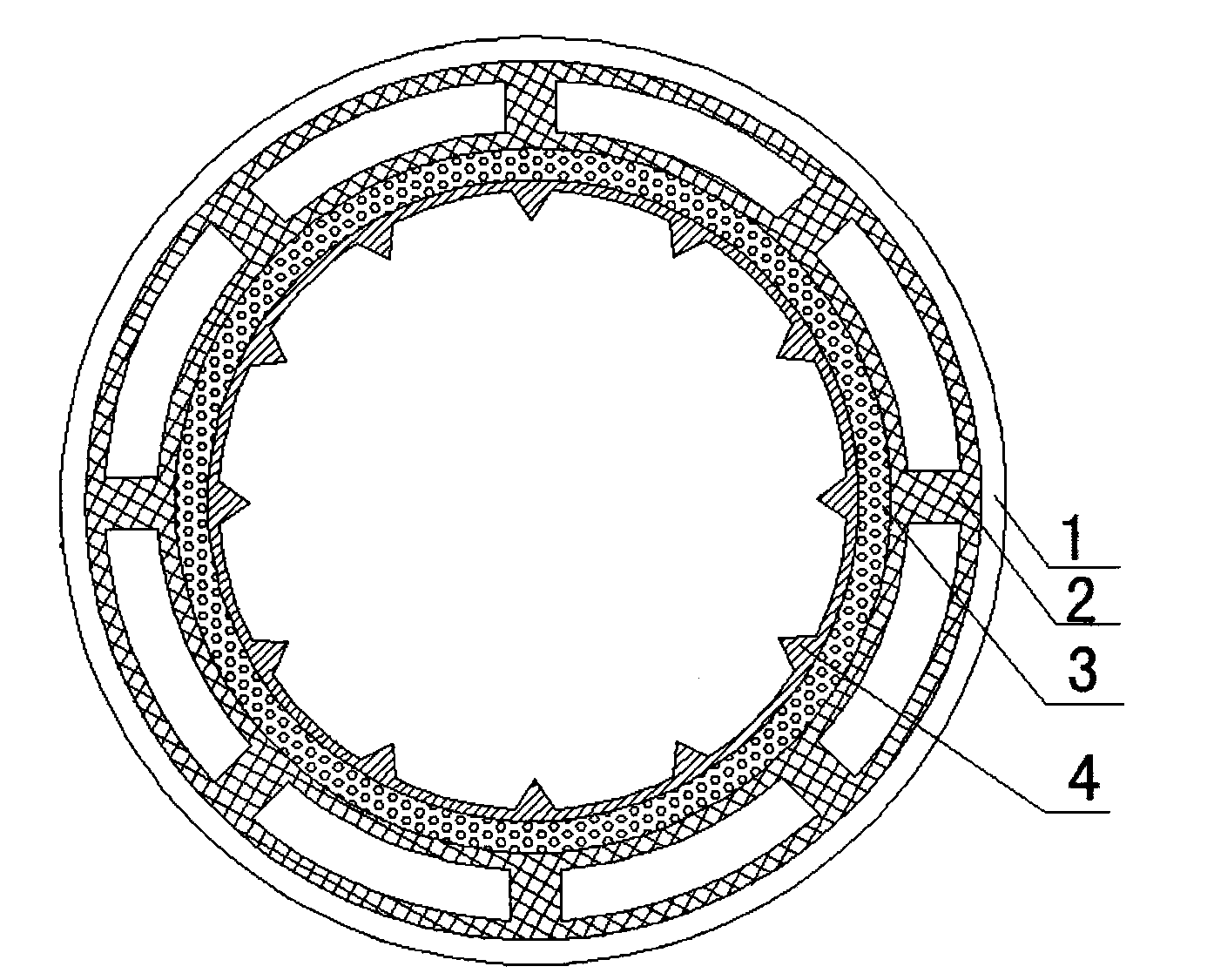

Noise ultra-attenuation color plastic composite polrvinyl chloride drainage pipe and manufacturing method thereof

ActiveCN102424713BReduce drainage noiseImprove sound insulationRigid pipesEnvironmental resistancePolyvinyl chloride

The invention discloses a noise ultra-attenuation color plastic composite polrvinyl chloride drainage pipe and a manufacturing method thereof, belonging to the field of drainage pipes. The wall of the noise ultra-attenuation color plastic composite polrvinyl chloride drainage pipe is of a four-layer composite structure and comprises a color ASA (Acetyl Salicilic Acid) layer, a PVC (Poly Vinyl Chloride) micro-foaming layer, a PVC hollow layer and a PVC internal helical layer from the outside to the inside. Three kinds of noise attenuation, i.e., noise attenuation of a hollow wall structure, noise attenuation of a micro-foaming structure and noise attenuation of an internal helical structure are combined, thus, the drainage noise of the plastic drainage pipe is greatly reduced, the drainagepipe has extremely good noise absorption, noise attenuation and noise insulation effects, and the aim of noise ultra-attenuation of the plastic pipe is achieved. The noise ultra-attenuation color plastic composite polrvinyl chloride drainage pipe has the advantages of keeping the favorable performances such as light weight, corrosion resistance, scaling prevention, flame retardance, wear resistance, good toughness, high impact strength, good gas tightness, capability of recycling, convenience and rapidness in installation, energy saving, sanitation, environment friendliness and the like of the traditional plastic drainage pipe and also has the advantages of excellent anti-aging performance and weather resistance, good noise attenuation effect, varied colors and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

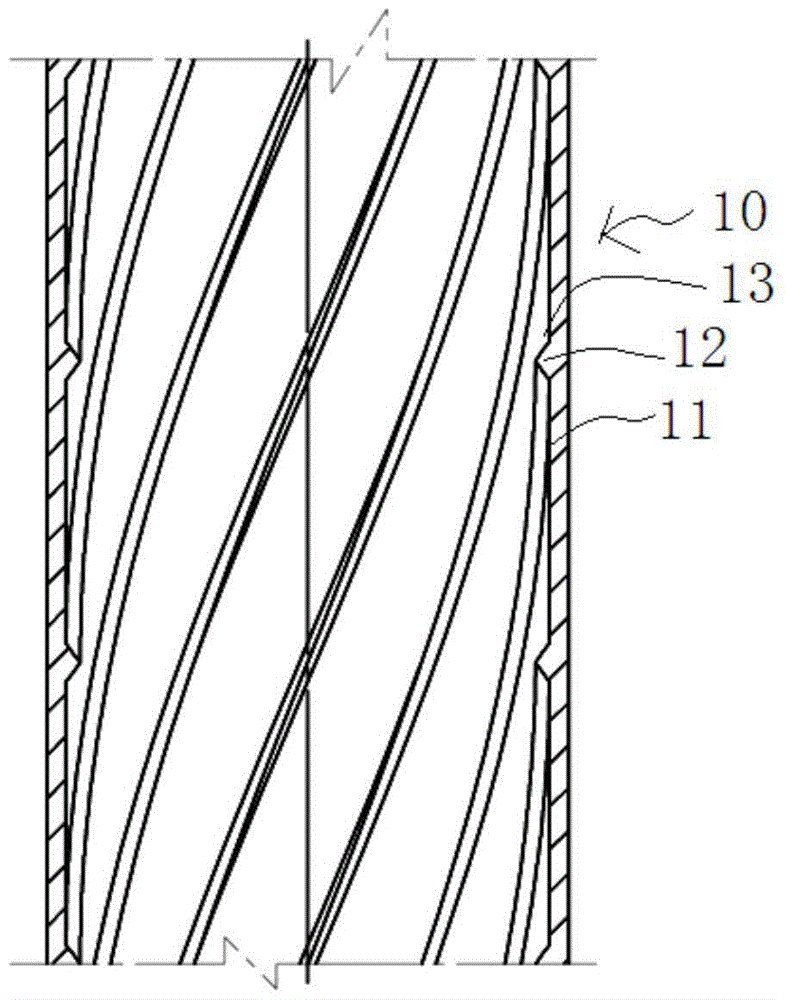

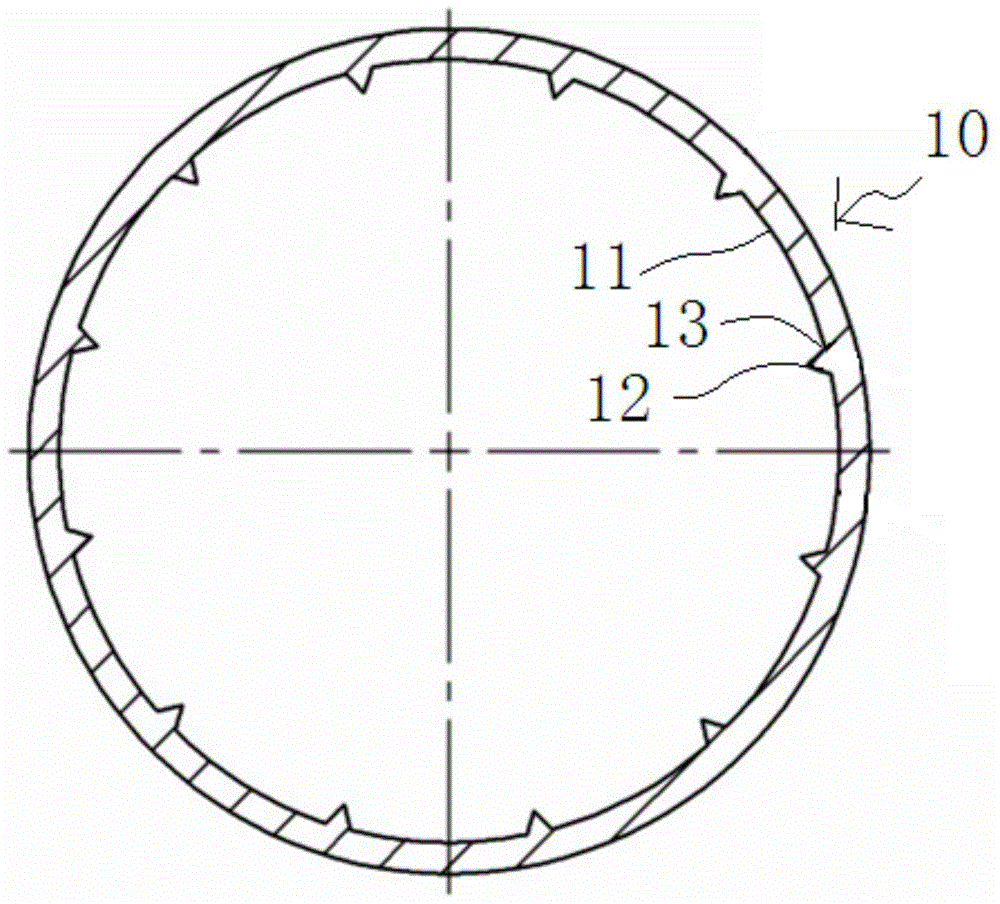

Building drainage plastic stack with spiral grooves

ActiveCN104565565AAvoid water plugging situationsAvoid destructionPipe elementsRigid pipesVertical tubeWater flow

The invention discloses a building drainage plastic stack with spiral grooves. The plastic stack comprises a plastic stack body, wherein the inner wall of the plastic stack body is coaxially and circumferentially provided with a plurality of spiral grooves along the axis of the stack; the junctions of the groove bottoms of the spiral grooves and the groove walls and the junctions of notches of the spiral grooves and the inner wall of the plastic stack body are all of circular arc transition structures. The junctions of the groove bottoms of the spiral grooves and the groove walls and the junctions of the notches of the spiral grooves and the inner wall of the plastic stack body are all of the circular arc transition structures, so the spiral grooves are of the streamline-shaped arc structures with small curvature, namely large curvature radius; the situation that the water flow moves towards the center of the stack to produce water blockage is avoided according to the theory of a fluid wall attachment effect, the fluctuation of pressure in the stack is reduced, the drainage flow rate within a certain pressure fluctuation range is improved, alternate impact of the water flow to the stack is also avoided, and the pipeline vibration and the drainage noise are greatly reduced.

Owner:上海深海宏添建材有限公司

A building drainage plastic riser with a spiral single blade

InactiveCN104674909BAvoid destructionReduce vibration and noiseDomestic plumbingFluidicsHelical blade

The invention discloses a building drainage plastic vertical pipe with a spiral single blade. The building drainage plastic vertical pipe comprises a plastic vertical pipe body, wherein the inner wall of the plastic vertical pipe body is coaxially provided with the spiral single blade along the axis direction of the vertical pipe; the connection part of the root part of the spiral single blade and the inner wall of the plastic vertical pipe body is of a circular arc transition structure. According to the pipe, the connection part of the root part of the spiral single blade and the inner wall of the plastic vertical pipe body is of the circular arc transition structure; the curvature is reduced greatly (the curvature radius is increased); according to the fluid wall attachment effect theory, when water in the pipe falls off along the pipe wall, the water flow is adsorbed to the pipe wall and cannot be removed so as to form a good wall attachment water film fluidic state, so that the situation that the water flow moves toward the center of the vertical pipe to generate water cork flow is prevented; the fluctuation of pressure in the pipe is reduced; the water drainage flow rate within a certain pressure fluctuation range is improved; the alternative impact by the water flow to the pipe wall is also prevented, so that the pipeline vibration and drained water noise are buffered greatly.

Owner:上海深海宏添建材有限公司 +1

Water draining tee capable of generating rotational flow

InactiveCN101608724BEnhance swirl effectReduce air pressure fluctuationsBranching pipesLarge mouthRotational flow

The invention relates to a water draining tee capable of generating rotational flow, which is connected into a whole by a vertical pipe body and a side pipe body; the side pipe body is spiral downwards at the right and is communicated with the right side of the vertical pipe body; the vertical pipe body is formed by a cylindrical pipe, a conical pipe and a bell mouth of an elastic sealing ring; the large mouth end of the conical pipe is connected with the lower end of the cylindrical pipe, and the inner diameter and the wall thickness of the large mouth end of the conical pipe are the same asthose of the cylindrical pipe; a small mouth end of the conical pipe is connected with the bell mouth of the elastic sealing ring, and the inner diameter and the wall thickness of the small mouth endof the conical pipe are the same as those of the bell mouth of the elastic sealing ring; a spiral guide vane is arranged on the conical pipe along the dextrorotation of the inner wall; a groove is arranged in the middle of the bell mouth of the elastic sealing ring and is internally provided with the elastic sealing ring; a side rotary pipe of the side pie body is spiral downwards at the right and is communicated with the right side of the cylindrical pipe, and the wall thickness of the side rotary pipe is the same as that of the cylindrical pipe; the included angle between the centre line ofthe side pipe body and the center line of the vertical pipe body is alpha, and the included angle between a guide inclined plane of the side pipe body and the center line of the vertical pipe body isgamma; the joint between the bottom of the side pipe body and the vertical pipe body takes on u-type transition, so that the water circulating capability of a water draining system is improved, and the water draining noise can be reduced.

Owner:北京建筑工程学院

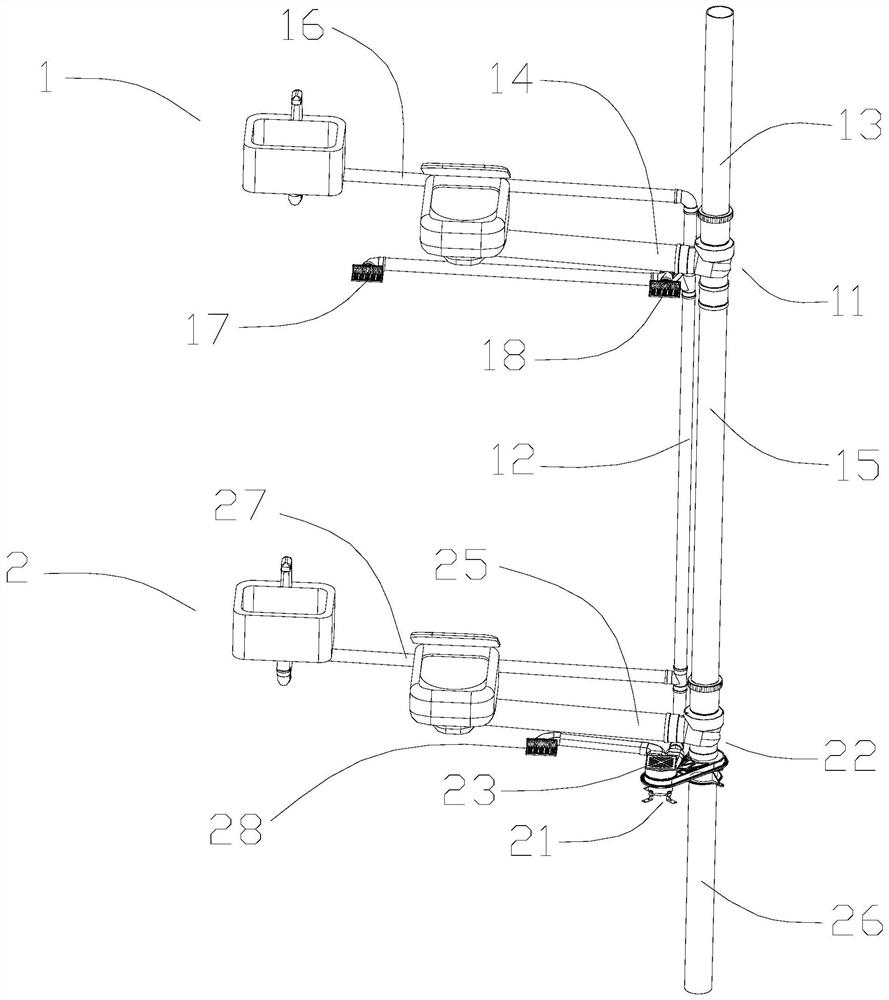

A non-falling slab drainage system for building jump floors

ActiveCN112031090BAdhesive swirl ensuresIncrease the radius of curvatureSewerage structuresClimate change adaptationFloor slabTube drainage

The invention provides a non-falling slab drainage system for a building jump, including a first-floor drainage system and a second-floor drainage system. The first-floor drainage system includes a first-floor drainage pipe assembly. The lower part is respectively connected with the upper general drainage pipe, the first floor toilet sewage pipe and the first lower general drainage pipe; the secondary drainage system includes horizontal pipe drainage components and secondary drainage pipes connected to the horizontal pipe drainage components and located on both sides components and water seal components, the upper part, side part and lower part of the secondary drainage pipe assembly are connected with the first lower general drainage pipe, the secondary toilet sewage pipe and the horizontal pipe drainage assembly respectively, and the horizontal pipe drainage assembly is connected with the second The main drainage pipes in the lower layer are connected; the interior of the horizontal pipe drainage assembly is a flat cavity structure, and the bottom surface of the cavity structure is inclined. Therefore, by adopting the horizontal pipe drainage assembly with a flat cavity structure, the occupied space is small, and drainage can be realized without lowering the floor.

Owner:KANGTAI PLASTIC SCI & TECH GRP

A building drainage plastic riser with a spiral groove

ActiveCN104565565BAvoid water plugging situationsAvoid destructionPipe elementsRigid pipesVertical tubeWater flow

The invention discloses a building drainage plastic stack with spiral grooves. The plastic stack comprises a plastic stack body, wherein the inner wall of the plastic stack body is coaxially and circumferentially provided with a plurality of spiral grooves along the axis of the stack; the junctions of the groove bottoms of the spiral grooves and the groove walls and the junctions of notches of the spiral grooves and the inner wall of the plastic stack body are all of circular arc transition structures. The junctions of the groove bottoms of the spiral grooves and the groove walls and the junctions of the notches of the spiral grooves and the inner wall of the plastic stack body are all of the circular arc transition structures, so the spiral grooves are of the streamline-shaped arc structures with small curvature, namely large curvature radius; the situation that the water flow moves towards the center of the stack to produce water blockage is avoided according to the theory of a fluid wall attachment effect, the fluctuation of pressure in the stack is reduced, the drainage flow rate within a certain pressure fluctuation range is improved, alternate impact of the water flow to the stack is also avoided, and the pipeline vibration and the drainage noise are greatly reduced.

Owner:上海深海宏添建材有限公司

Washing machine

ActiveCN112011969APrevent splashReduce drainageOther washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention relates to a washing machine which comprises a washing barrel, a water collecting device and a splash-proof structure, and the washing barrel is a water containing barrel during washing;the water collecting device is arranged outside the lower part of the washing barrel; the splash-proof structure comprises a splash-proof grid, and the splash-proof grid is arranged in the water collecting device. The splash-proof grid prevents water discharged from the washing barrel from splashing out of the water collecting device from a position between the water collecting device and the washing barrel, buffers drainage and reduces drainage noise.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

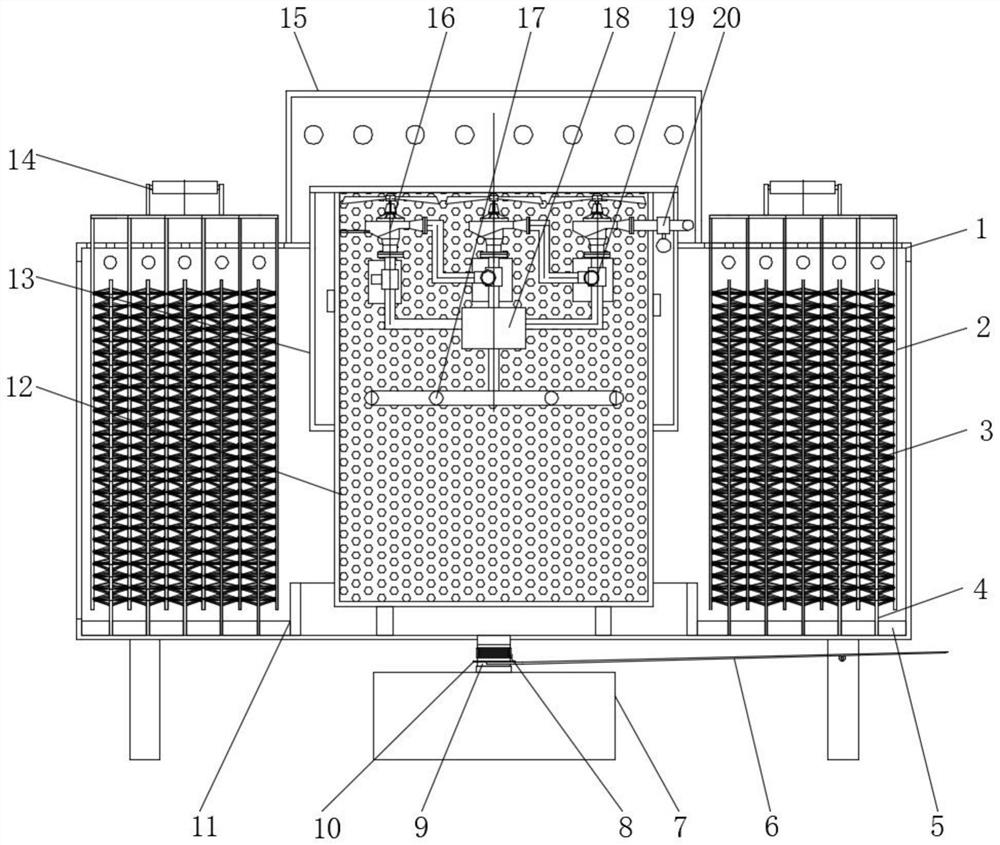

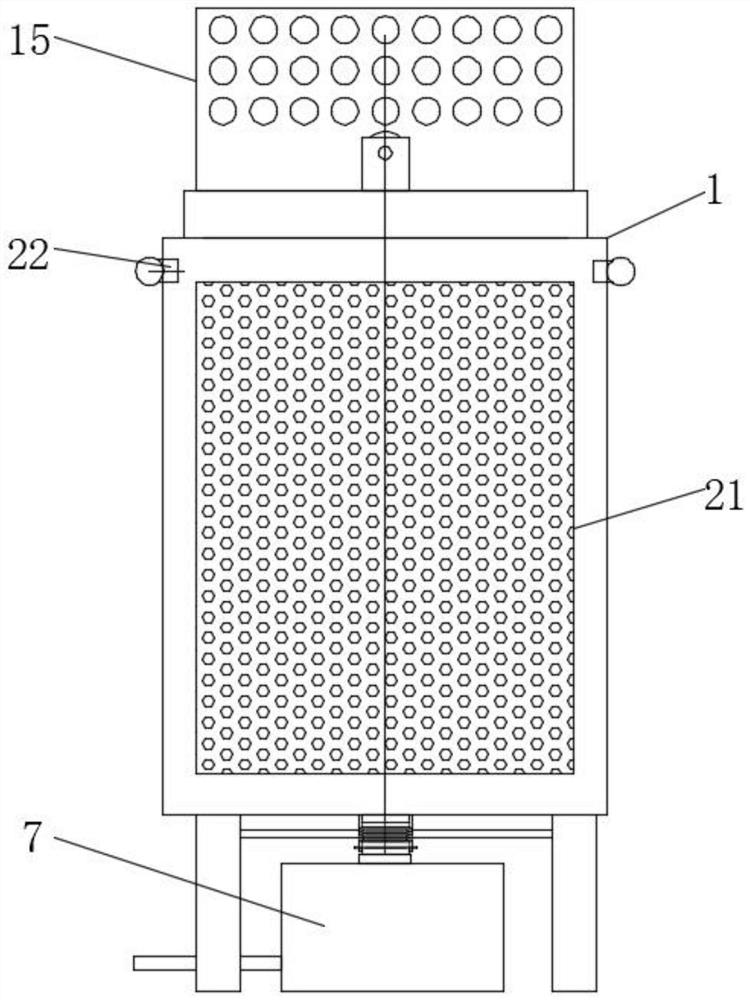

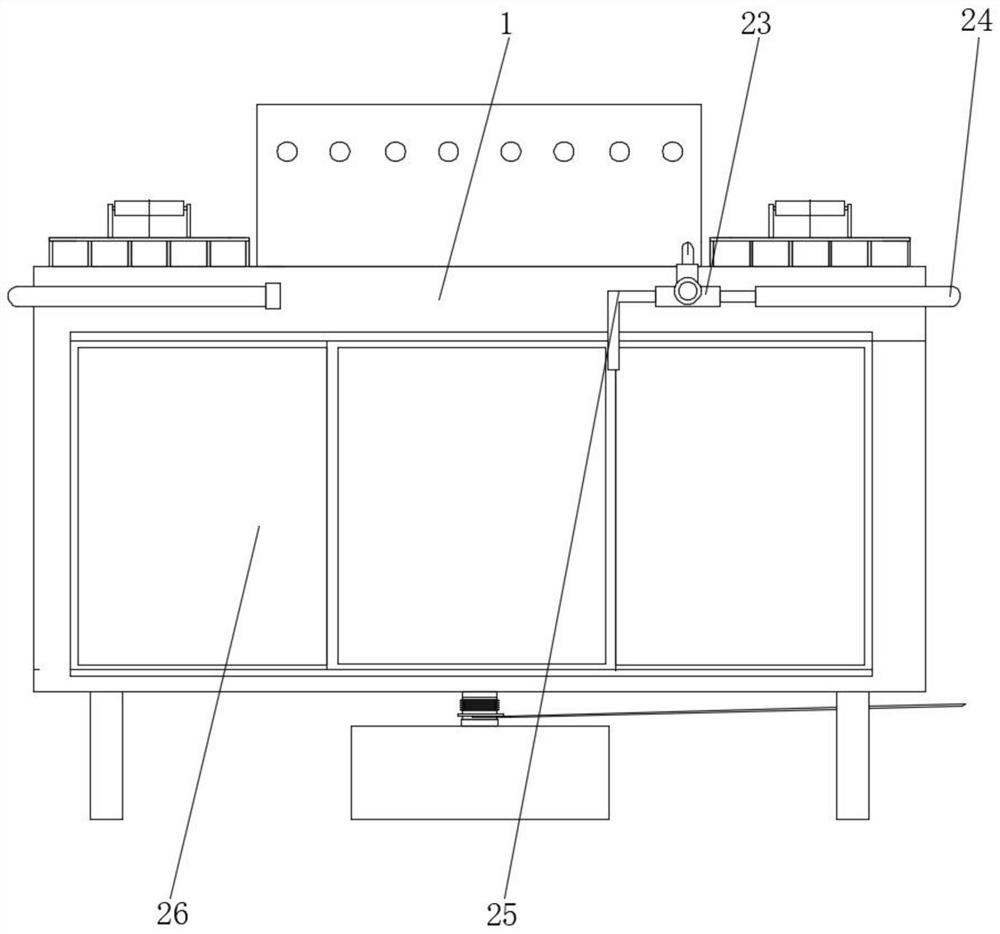

Efficient, durable and ultra-low-noise intelligent electric-free cooling tower

PendingCN111829360AReduce noiseEasy to cleanCorrosion preventionSound producing devicesLow noiseSound sources

The invention discloses an efficient, durable and ultra-low-noise intelligent electric-free cooling tower. The efficient, durable and ultra-low-noise intelligent electric-free cooling tower comprisesa cooling tower box body, wherein an exhaust port is formed in the middle position of the top of the cooling tower box body, meanwhile anechoic chambers are formed in the exhaust port and the corresponding cooling tower box body, the anechoic chambers are connected to the inner wall of the cooling tower box body through brackets, the anechoic chambers are of cylindrical structures with openings atthe tops, and a plurality of through holes are correspondingly formed in the outer surfaces and the bottoms of the anechoic chambers; and a limiting pipe is welded to the exhaust hole of the coolingtower box body. According to the efficient, durable and ultra-low-noise intelligent electric-free cooling tower, holes are formed in the inner walls of the anechoic chambers, one part of the sound model emitted by an internal sound source in the cooling tower is weakened through reflection, one part is weakened by through-hole interference, the space between the anechoic chambers and the cooling tower box body can be used for weakening the sound again, secondly, the installation part of a hydraulic turbine is provided with a limiting pipeline between the anechoic chambers and the cooling towerbox body, the work noise of the hydraulic turbine is further weakened, and the demand of ultra-low noise is achieved.

Owner:LIYANG CITY GOLDEN LAND ENERGY TECH CO LTD

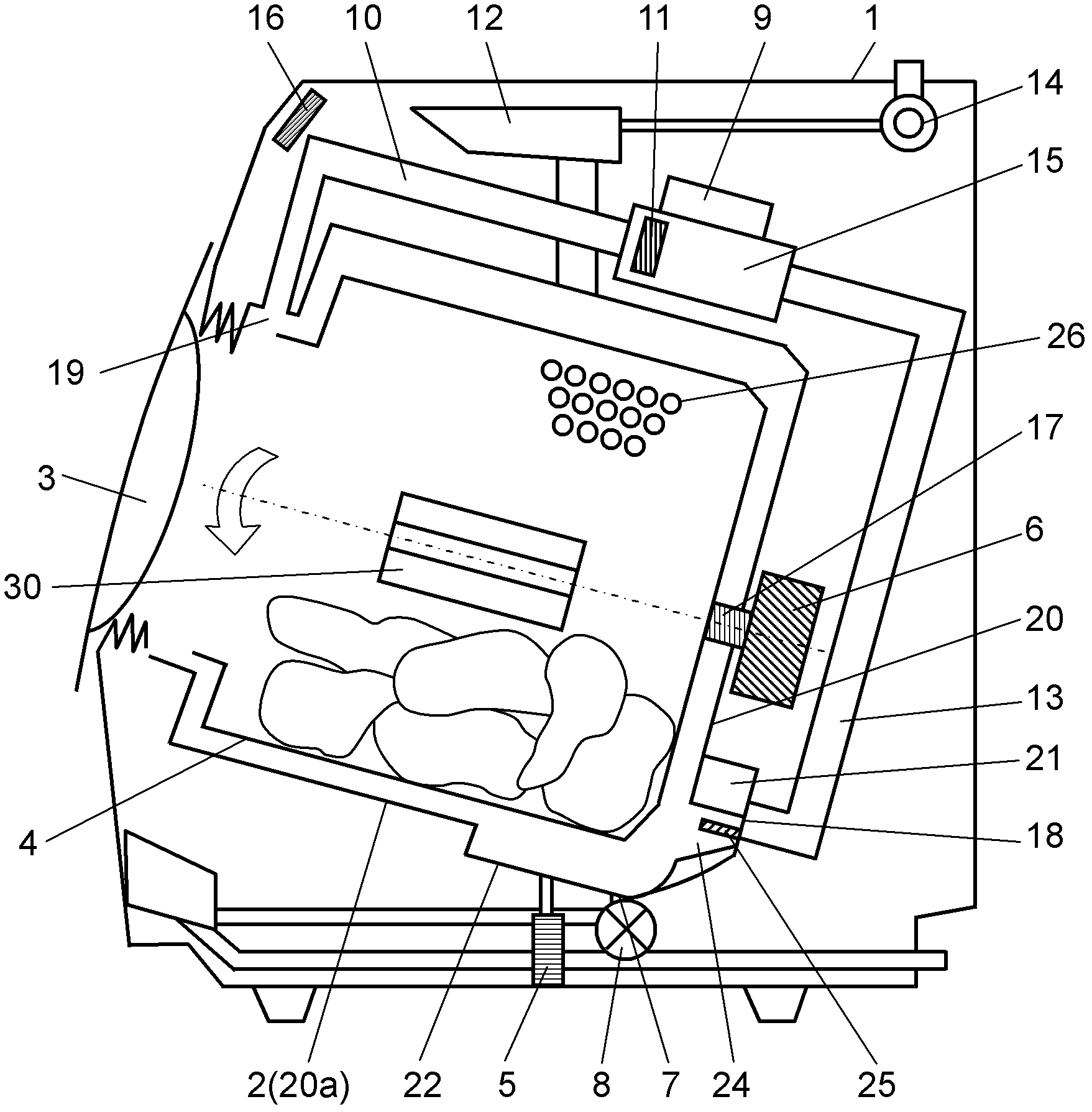

A low-noise groove diversion swirl joint

ActiveCN104390084BImprove hydraulic conditionsReduce positive and negative pressure fluctuationsPipe elementsBranching pipesLow noisePipe water

The invention discloses a low-noise groove diversion type vortex joint. The low-noise groove diversion type vortex joint comprises an upper body, a main body and a lower body, wherein the upper body and the main body are connected through a thread; the upper body and the lower body are combined to a vertical pipe water flowing channel; a transverse pipe water flowing channel is formed in the main body; a transverse pipe lateral water inlet baffle plate is arranged at one side of the transverse pipe water flowing channel; a main body water inlet is formed in the other side of the transverse pipe water flowing channel; the main body and the lower body are connected through a thread; a conical transition section is arranged at the lower part of the lower body; and a lower body water outlet is formed in the lower part of the conical transition section. The low-noise groove diversion type vortex joint has the advantages of high drainage flow, low drainage noise, saving of building area, reduction of comprehensive cost, energy conservation and environmental protection.

Owner:浙江中财管道科技股份有限公司

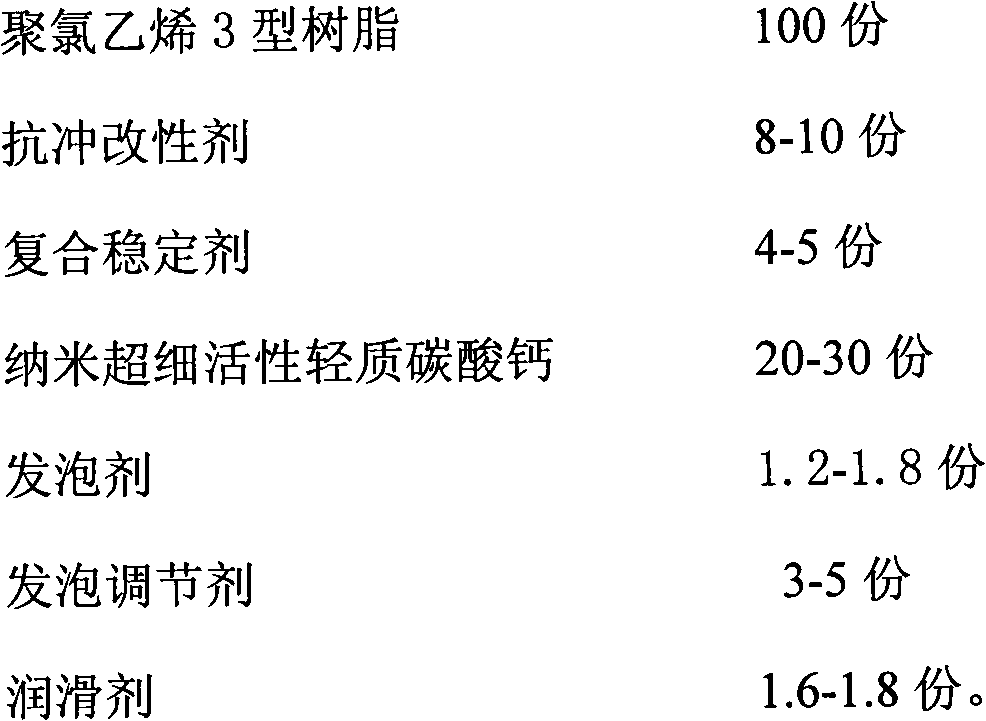

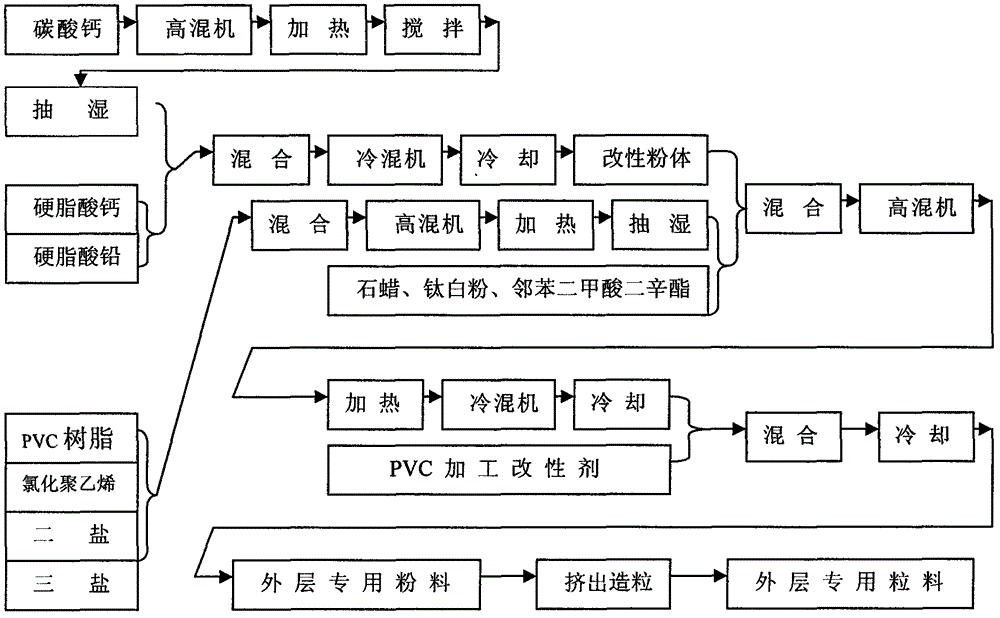

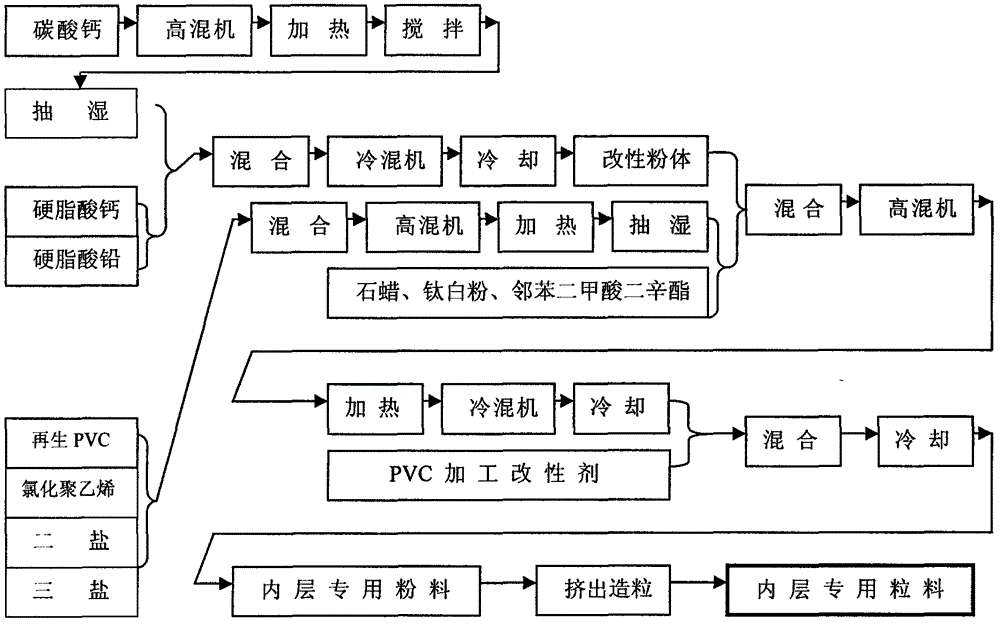

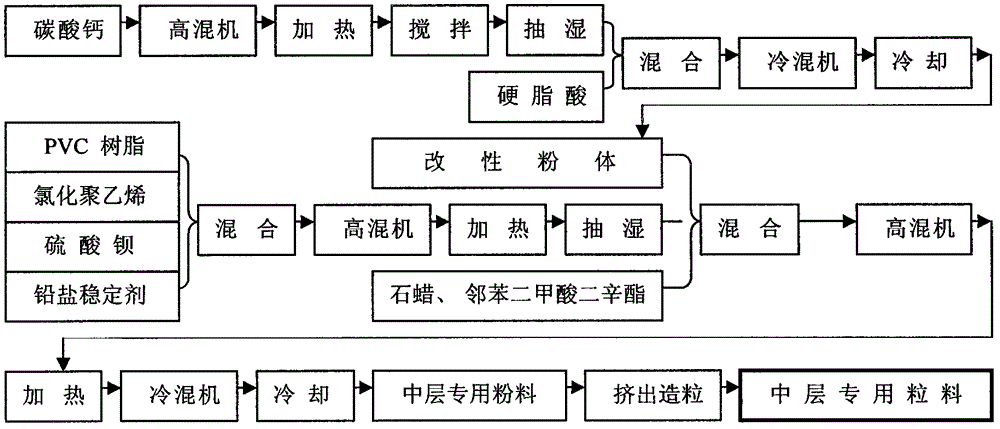

Three-layer noise reduction drainage pipe and manufacture method thereof

The invention discloses a three-layer noise reduction drainage pipe, which comprises a drainage pipe body, wherein the drainage pipe body is a three-layer co-extrusion composite pipe formed by an impact-resistance outer layer, a noise reduction middle layer and an impact-resistance inner layer through co-extrusion. A manufacture method of the three-layer noise reduction drainage pipe comprises the following steps that: 1, special materials for forming the impact-resistance outer layer, the noise reduction middle layer and the impact-resistance inner layer are respectively prepared; 2, the prepared special materials are used for respectively preparing the impact-resistance outer layer, the noise reduction middle layer and the impact-resistance inner layer, and then, the three-layer noise reduction drainage pipe is formed through one-step co-extrusion by a three-layer co-extrusion composite mold head. The noise of the drainage pipe can be effectively reduced, the intensity of the drainage pipe is enhanced, and simultaneously, the manufacture cost is reduced. The three-layer co-extrusion structure has the advantages that the noise reduction effect is obvious, good impact intensity and tensile intensity are realized, the manufacture process step is simple and convenient, and the three-layer noise reduction drainage pipe can be widely applied to drainage pipe systems of various buildings.

Owner:ZHEJIANG SANLENG PLASTIC

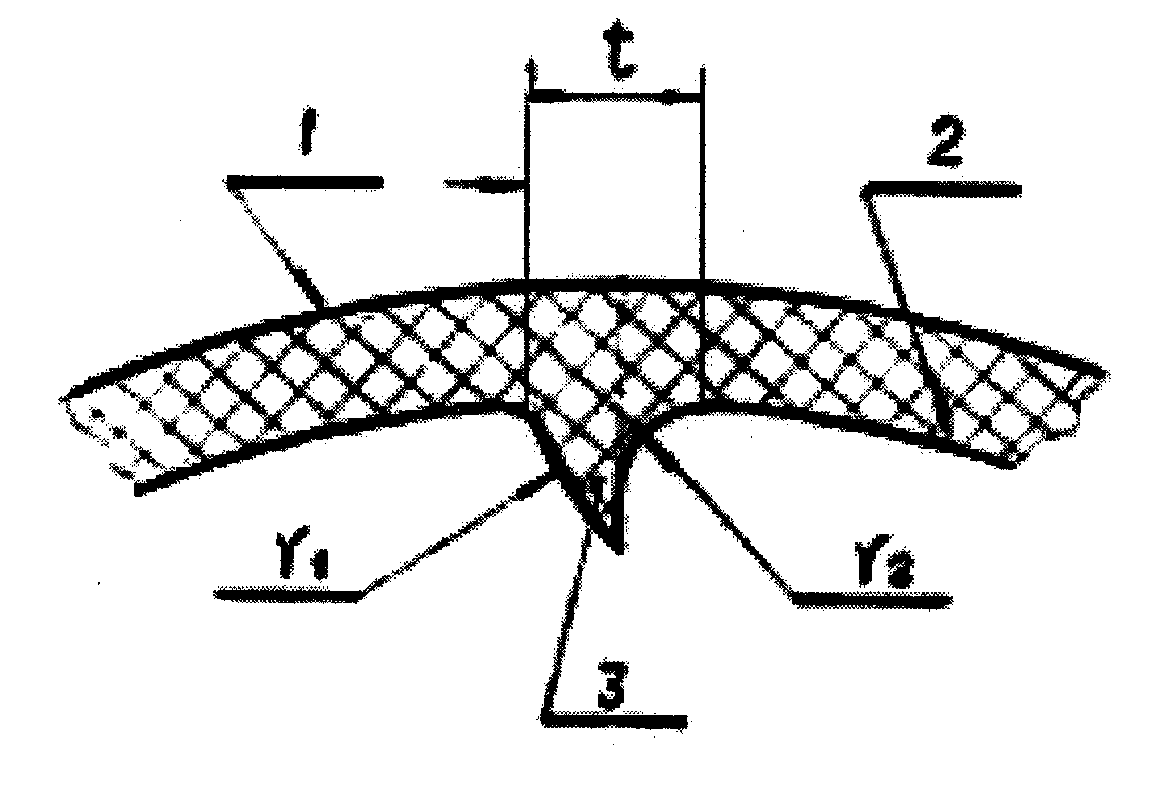

Pipe and pipe connector with special resin layer capable of reduicing noise

InactiveCN1239834CReduce drainage noiseReduce noiseDomestic plumbingPipe elementsPolyolefinWater discharge

Provided are a pipe and a pipe joint excellent in noise insulation effect while preventing any degradation of the water discharge capacity of an existing pipe, having strong resistance against chemical substances, and with noise reduction function. A special resin layer with noise reduction function is tightly fitted to an outer circumferential surface of a water discharge pipe and a pipe joint formed of hard PVC. The special resin layer with noise reduction function is basically formed of a PVC resin and a plasticizer, and calcium carbonate, etc., can be further added thereto. An inner layer may be formed of a polyolefin resin in place of the hard PVC resin.

Owner:PYUNG HWA

Ground assembly type quick drainage structure

PendingCN110158402AImprove drainage efficiencySave human effortSewerage structuresPaving gutters/kerbsEngineeringDrainage ditch

The invention provides a ground assembly type quick drainage structure. The ground assembly type quick drainage structure comprises a drainage ditch formed in the ground, the top of the drainage ditchcommunicates with a water inlet, the water inlet is formed in the ground, an L-shaped installation frame extending into the drainage ditch is fixedly installed in the position of the water inlet andelastically connected with a first arc-shaped aluminum plate, and the first arc-shaped aluminum plate faces the top corner of the drainage ditch. Compared with the prior art, water inflow efficiency can be improved on the basis that the beauty of the water inlet is reserved.

Owner:GOLD MANTIS CONSTR DECORATION

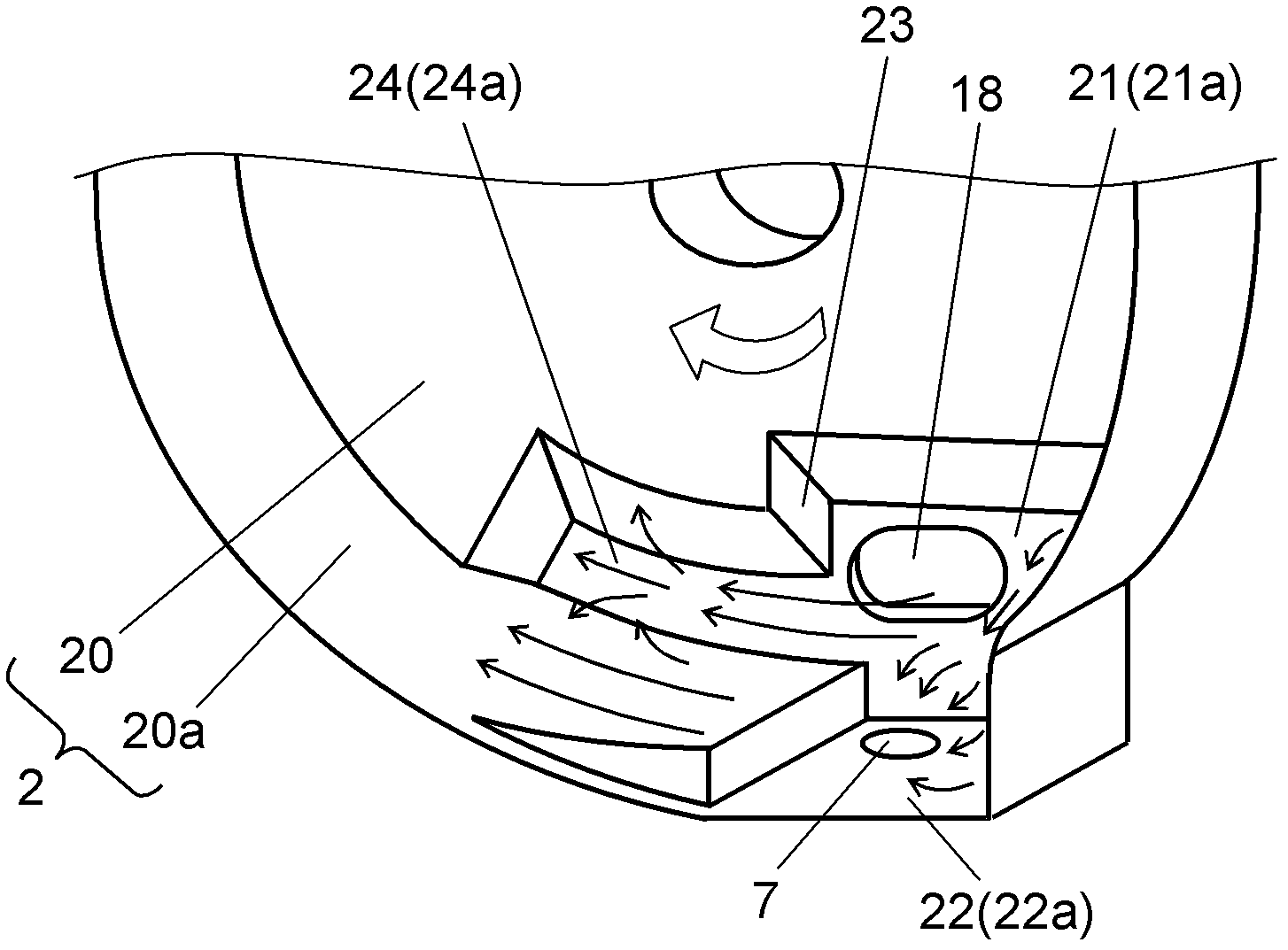

Roller-type washing and drying machine

ActiveCN102733141BAvoid turbulenceStable drainageOther washing machinesWashing machine with receptaclesEngineeringWater holding

The invention provides a roller-type washing and drying machine comprising a rotation barrel which has multiple through holes on surrounding walls, a water holding trough of the rotation barrel, an air supplying unit for supplying the air to the rotation barrel, a heating unti for heating the air, an air supplying path for guiding the heated air to the water holding trough, a heat exchange path for guiding the air to the air supplying unit and dehumidifying, and a control unit for controlling each process, wherein the water holding trough comprises a recess arranged on the back of the water holding trough, and a water path which extends along the rotating direction during the dehydration process and is connected with the recess; and as the turbulence is generated when the water in the crack between the undersurface of the rotation barrel and the back of the water holding trough runs into the fault wall of the recess of the water holding trough, the invention can prevent the situation during the dehydration process, thus significantly reducing the uncomfortable dewatering noise during the dehydration process and realizing stable performance for dewatering.

Owner:PANASONIC CORP

Washing machine and drainage control method thereof

InactiveCN106811928AGuaranteed to workReduce drainage noiseOther washing machinesTextiles and paperElectric machineryPulp and paper industry

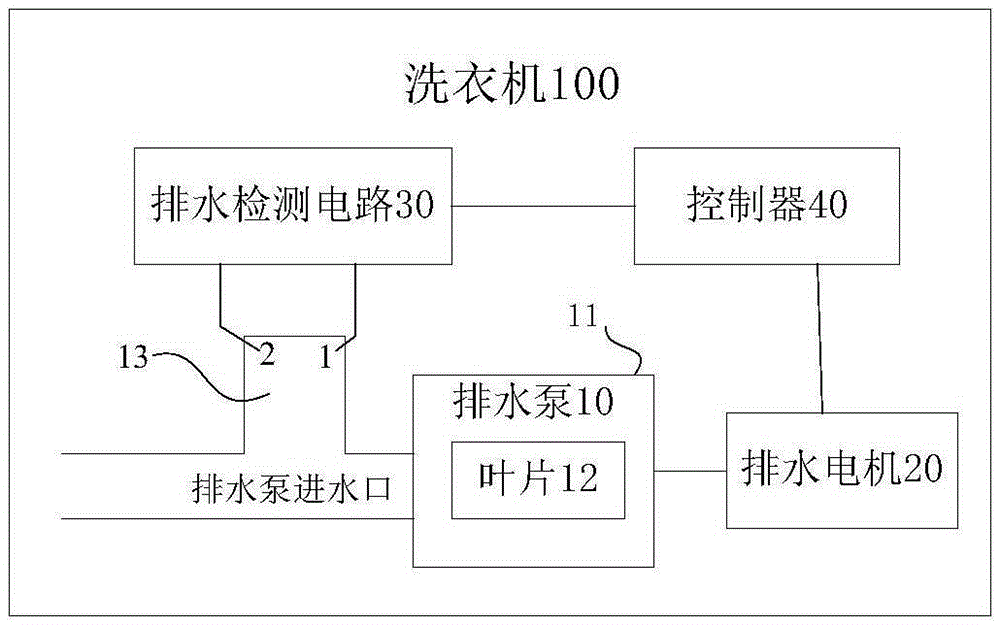

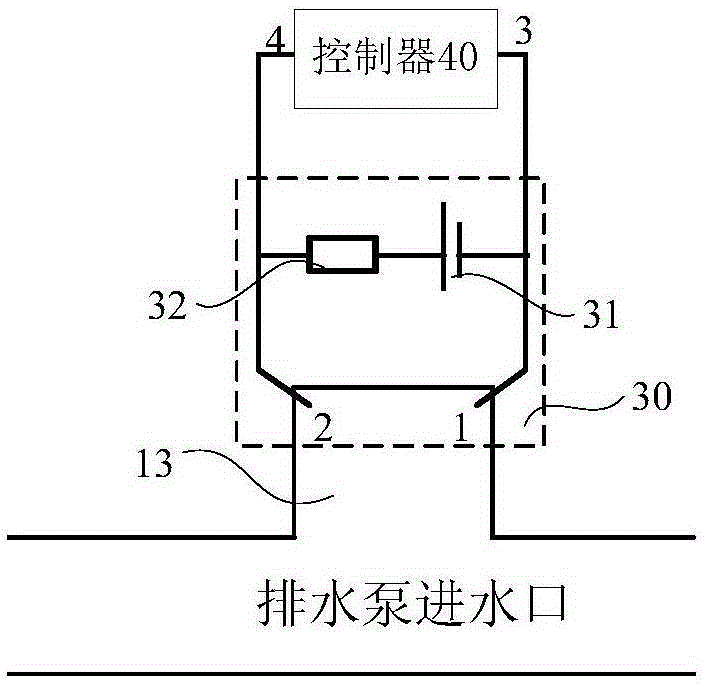

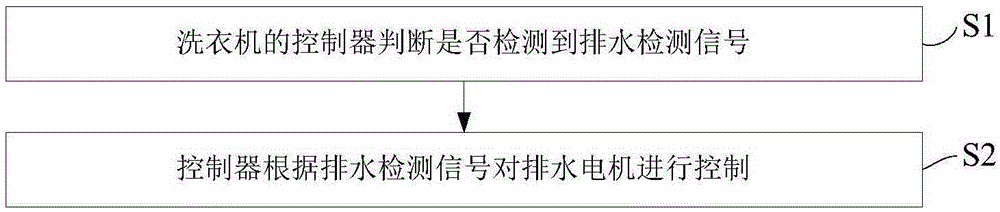

The invention discloses a washing machine. The washing machine comprises a drainage pump, a drainage motor, a drainage detecting circuit and a controller, wherein the drainage motor is used for driving the drainage pump, the drainage pump comprises a pump shell and blades, the pump shell comprises a water inlet, and a cavity is arranged at the water inlet and communicated with the water inlet; the drainage detecting circuit comprises a first detecting end and a second detecting end, the first detecting end and the second detecting end are located in the cavity, and the drainage detecting circuit is connected and generates a drainage detecting signal when the water level in the cavity is larger than a preset water level; the controller is respectively connected with the drainage motor and the drainage detecting circuit and used for controlling the drainage motor according to the drainage detecting signal. By the washing machine, drainage noise can be lowered, and noise quality can be improved. The invention further discloses a drainage control method of the washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com