Pipe and pipe connector with special resin layer capable of reduicing noise

A technology of piping device and resin layer, which is applied in the direction of indoor sanitary piping device, pipe/pipe joint/pipe fitting, pipe connection arrangement, etc., can solve the problem of reducing the life of the building where the pipe is installed, obstructing drainage flow, and chemical corrosion resistance. Weakness and other problems, to achieve the effect of preventing shrinkage rate changes, preventing deterioration and deformation, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

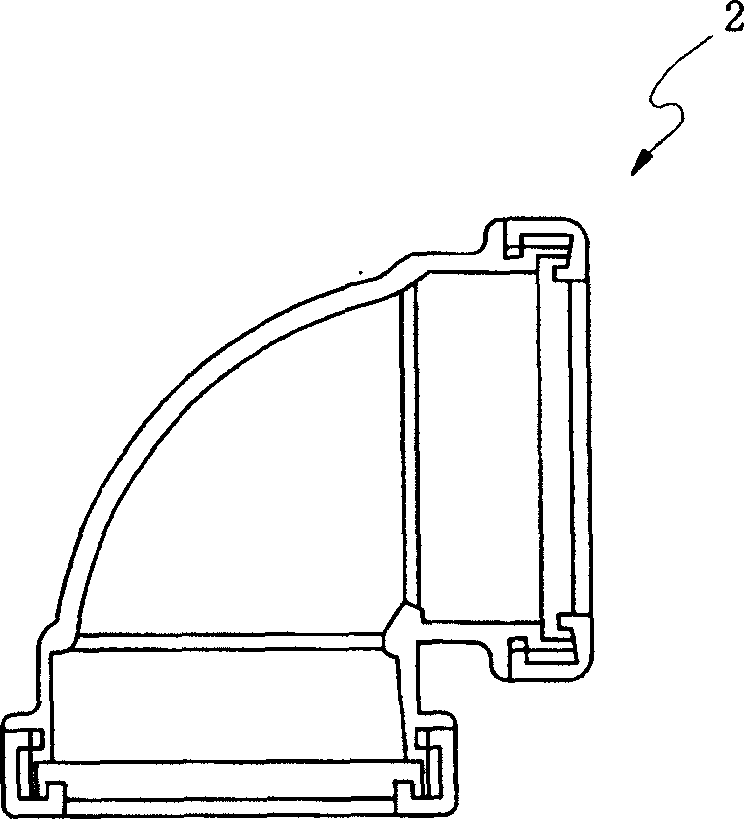

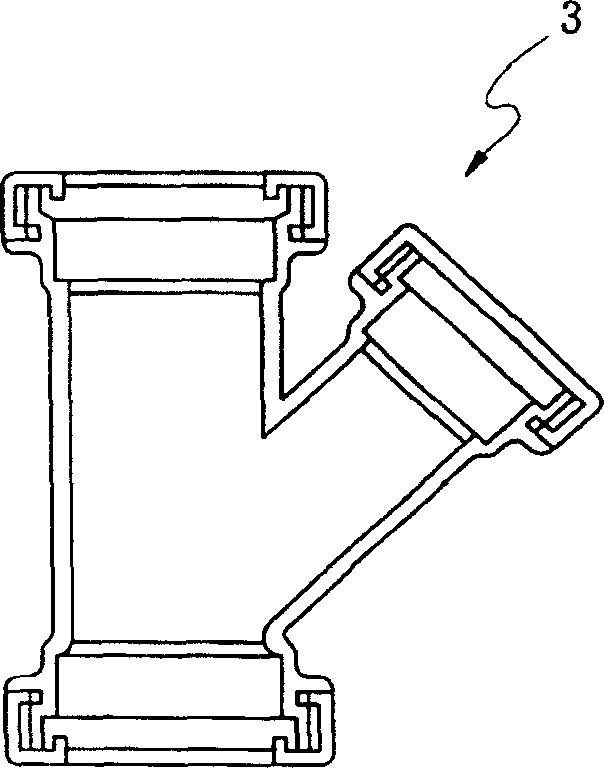

[0056] Preferred embodiments of the present invention will be described in detail below using the drawings. However, due to the types of pipe joints such as Figure 2 to Figure 6 The various forms shown, the following only in the pipe joint figure 2 Generic elbow fittings shown, and modified Figure 8 The preferred embodiment of the present invention is illustrated on the basis of the shown elbow fitting having a particular resin.

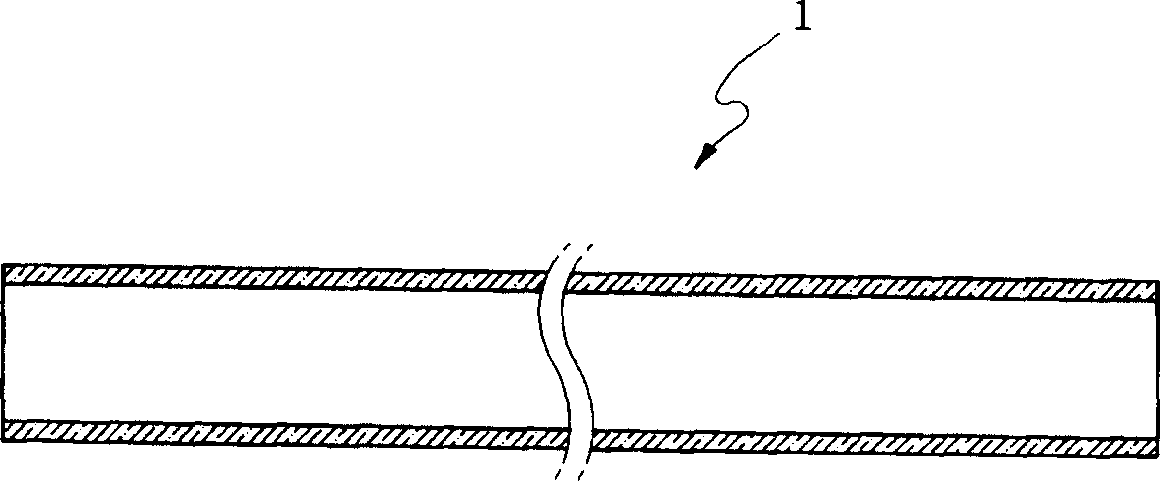

[0057] Figure 7 A cross-sectional view showing a straight pipe with a special resin layer that can reduce noise adopted in the present invention, Figure 8 A perspective view showing an elbow pipe joint manufactured using the present invention with a special resin layer for reducing noise.

[0058] In order to achieve the desired purpose, in the present invention, the hard PVC layer 9 is used to make figure 1 and figure 2 A special resin layer 10 is formed on the outside of the shown general straight pipe 1 and general elbow joint 2 . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com