Closestool blowdown structure and closestool

A toilet and control mechanism technology, applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of large pipe diameter, large water volume, and high water pressure, so as to save water, reduce noise, and reduce drainage resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

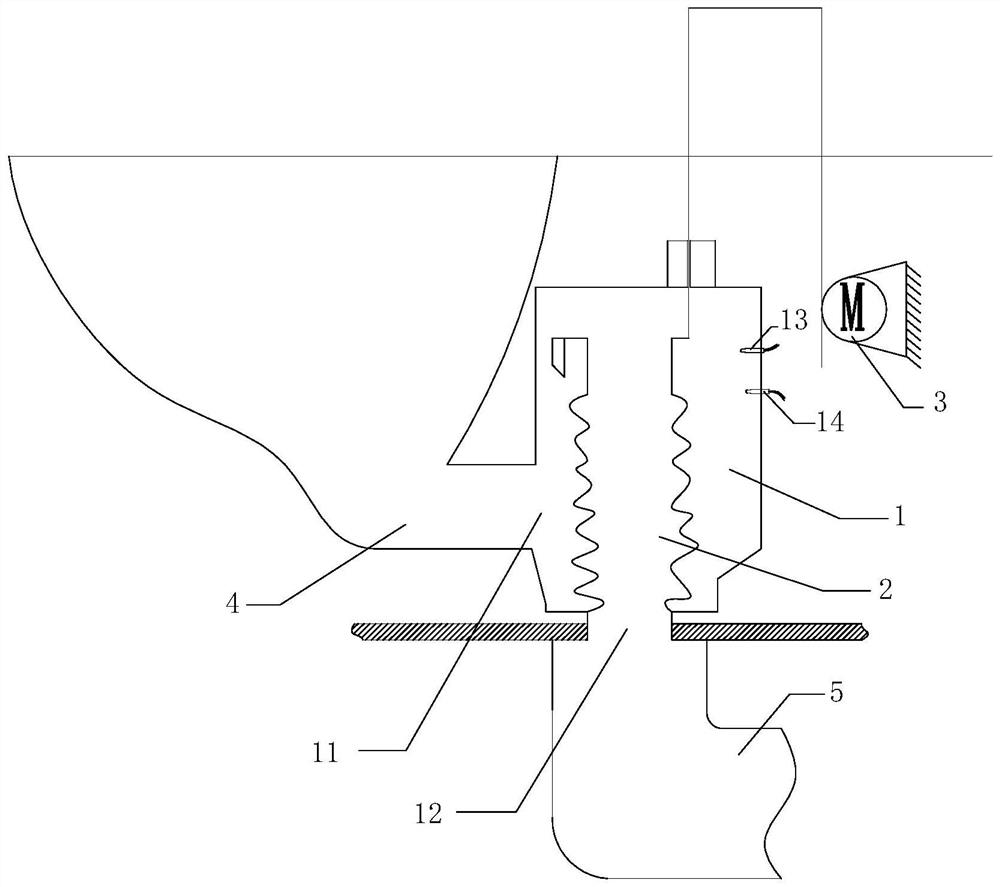

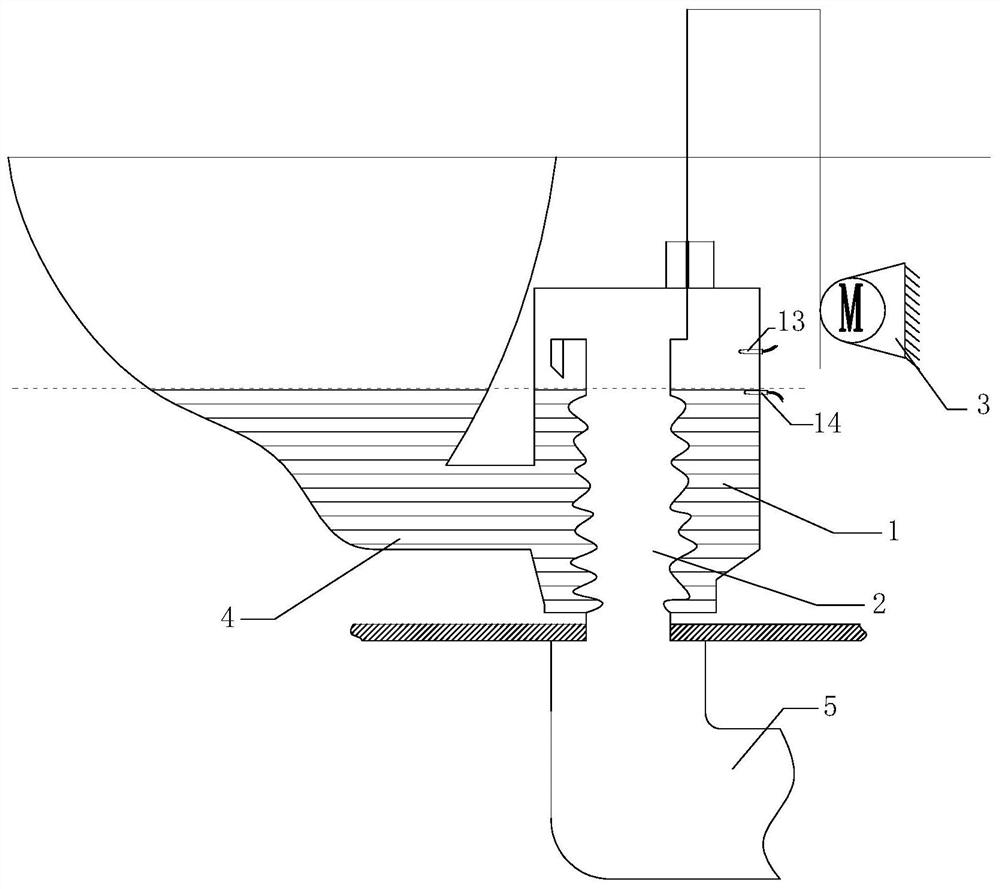

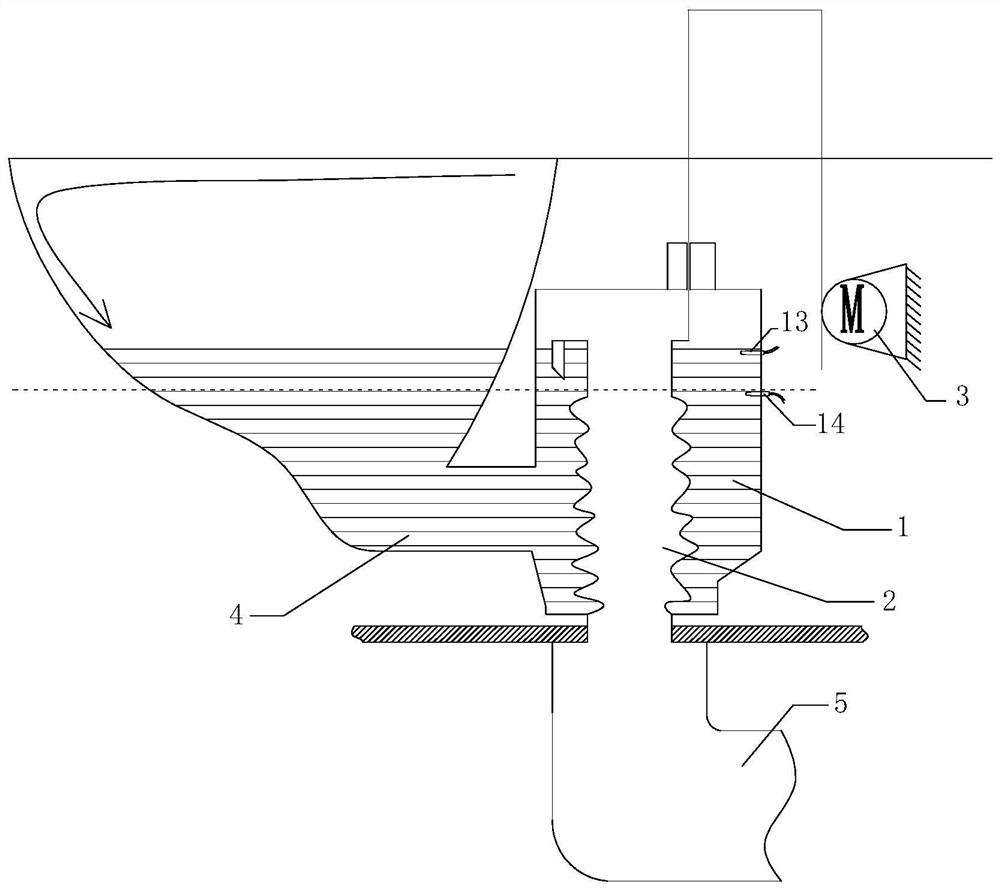

[0034] refer to figure 1 , a toilet sewage structure, comprising: a buffer chamber 1, an on-off valve 2 and a control mechanism 3 for driving the on-off valve 2 up and down; the water inlet 11 of the buffer chamber 1 communicates with the toilet sewage pipe 4, and the outlet of the buffer chamber 1 The water outlet is communicated with the sewage sewer pipe 5 .

[0035] The lower end of the on-off valve 2 communicates with the sewage and sewage pipeline 5 through the water outlet 12, and the upper end of the on-off valve 2 is provided with a water inlet; the control mechanism 3 controls the on-off valve 2 to move between the highest position and the lowest position, when the control mechanism 3 When the control on-off valve 2 is raised to a high position, the water inlet is higher than the water cover when the water is not flushed, such as figure 2 As shown, this can ensure that the water in the toilet and the buffer chamber 1 will not be discharged from the on-off valve 2, ...

Embodiment 2

[0041] refer to Figure 7-12 The difference between this embodiment and Embodiment 1 is that in this embodiment, the on-off valve has a water stopper 6, and the water stopper is used to open or close the water outlet 12 of the buffer chamber 2.

[0042] The water inlet of the buffer chamber 1 communicates with the toilet sewage pipe 4, the water outlet 12 of the buffer chamber 1 communicates with the sewage sewer pipe 5, and the water stopper 6 is used to open or close the water outlet 12; as Figure 7 shown.

[0043] A liquid level sensor 15 is arranged in the buffer chamber 1, and the position of the liquid level sensor 15 is higher than the water cover when not flushing, such as Figure 8As shown; when the toilet is flushed, the liquid level in the buffer chamber 1 rises, and when the liquid level in the buffer chamber 1 reaches the position where the first liquid level sensor 13 is located, the control mechanism 3 drives the water stopper 6 to open the buffer chamber 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com