Noise ultra-attenuation color plastic composite polrvinyl chloride drainage pipe and manufacturing method thereof

A technology of compounding polyvinyl chloride and drainage pipes, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of anti-aging, single color drainage noise, etc., and achieve convenient and fast installation and high impact strength. , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

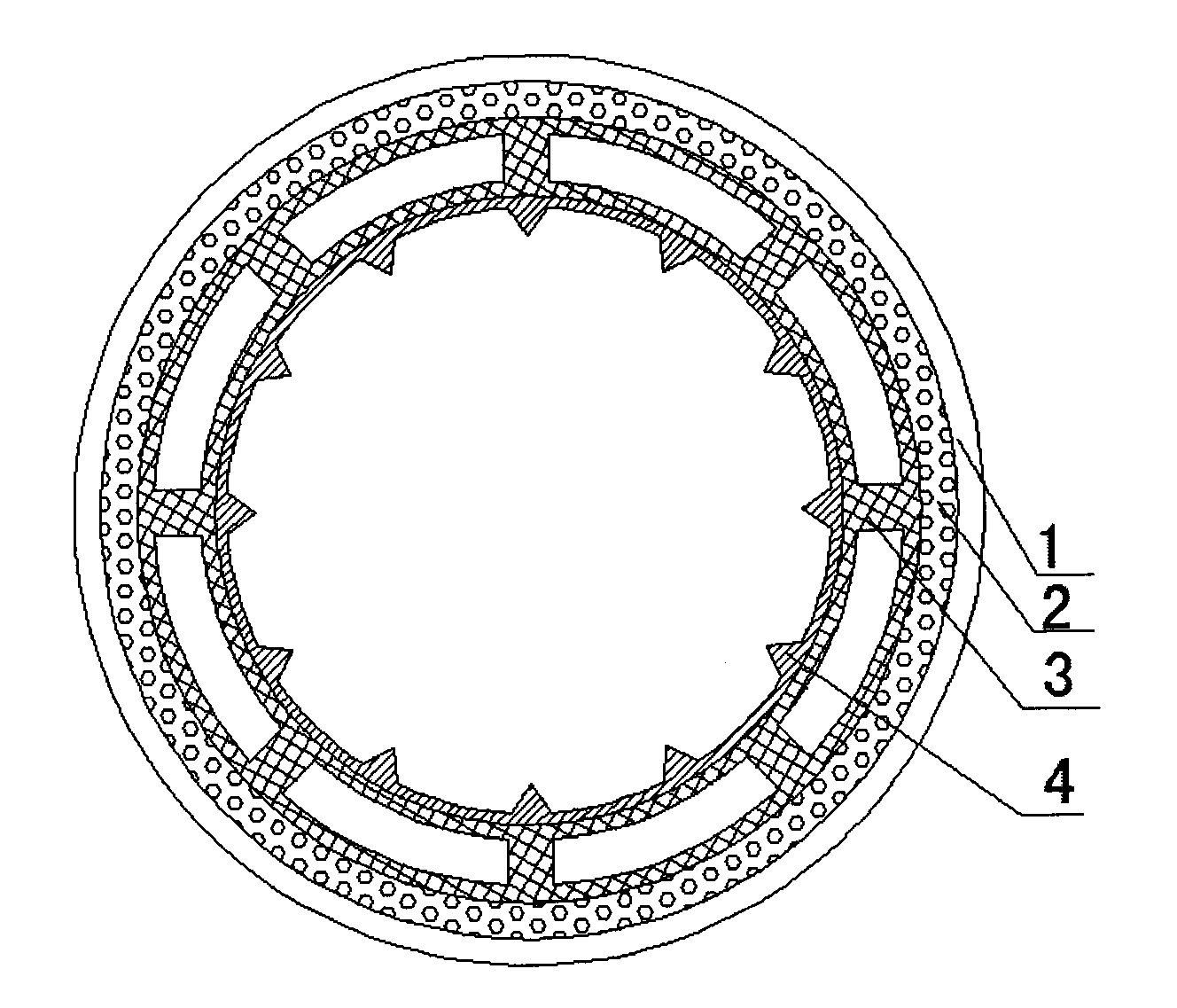

[0026] Example 1: The four-layer composite structure of the pipe wall is sequentially from inside to outside: PVC inner spiral layer 4, PVC hollow layer 3, PVC micro-foaming layer 2, and colored ASA outer layer 1.

[0027] Material:

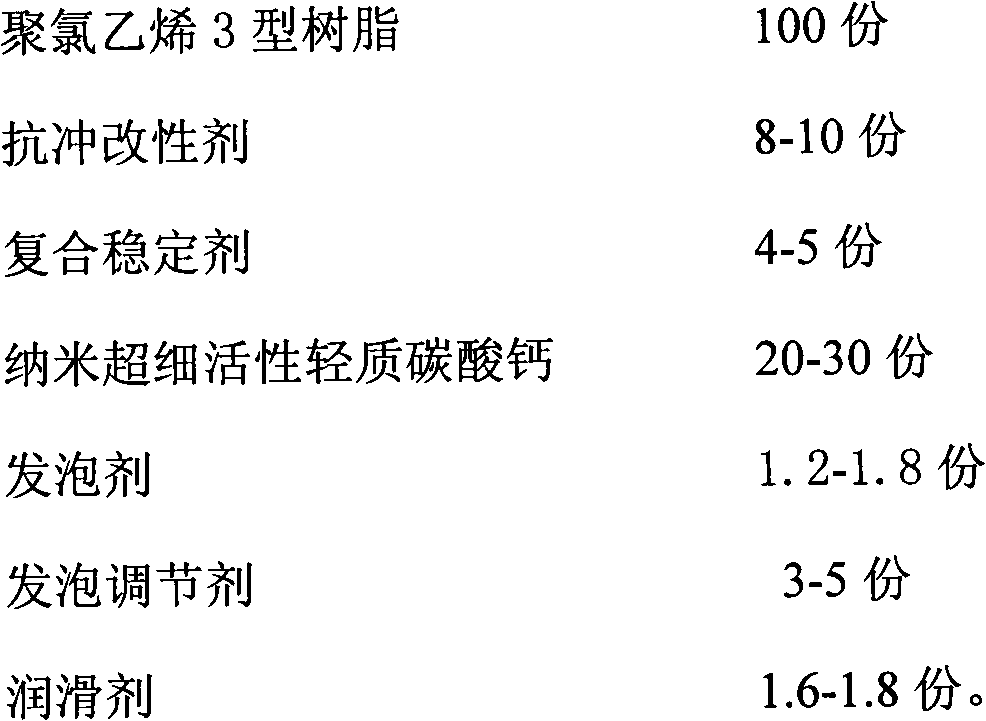

[0028] 1. PVC micro-foaming layer: 100 parts of polyvinyl chloride type 3 resin, PH3055 parts of lead salt, 10 parts of impact modifier MBS B-56110 parts, 20 parts of nano-ultrafine active light calcium carbonate, 1.5 parts of AC foaming agent , 4 parts of foam regulator PA600 produced in Japan, 1.8 parts of lubricant (stearic acid 40%, PE wax 60%).

[0029] 2. PVC hollow layer: 100 parts of polyvinyl chloride type 5 resin, 10 parts of impact modifier CPE135A, 54 parts of composite stabilizer lead salt PH3054, 30 parts of nanometer ultrafine active light calcium carbonate, lubricant (stearic acid 40 %, PE wax 60%) 1.5 parts.

[0030] 3. PVC inner helical layer: same as PVC micro-foaming layer.

[0031] Add the colored ASA to a low-speed mixer ...

Embodiment 2

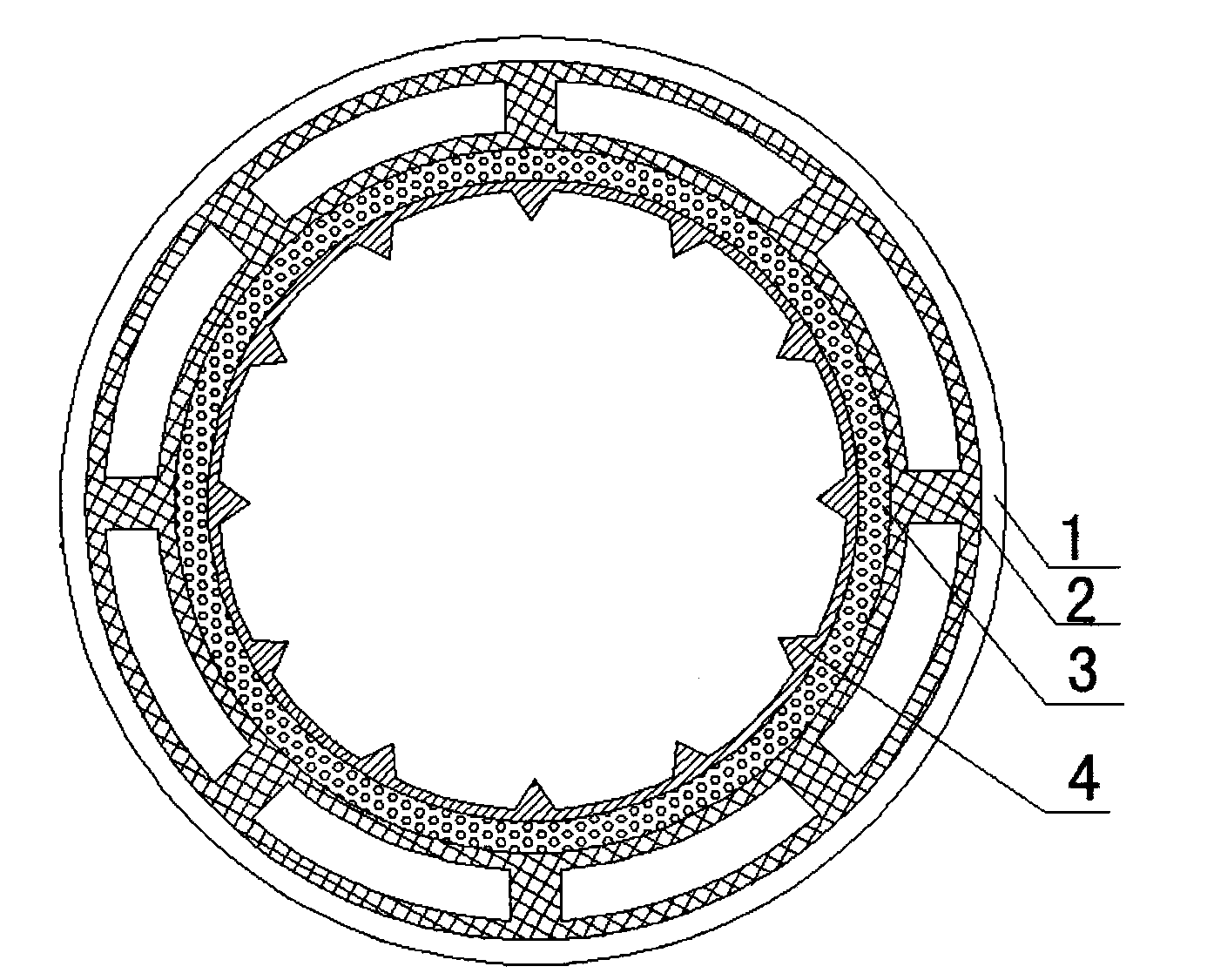

[0033] Example 2 The four-layer composite structure of the pipe wall is sequentially from inside to outside: PVC inner spiral layer 4, PVC micro-foaming layer 2, PVC hollow layer 3, and colored ASA outer layer 1.

[0034] 1. PVC micro-foaming layer: 100 parts of polyvinyl chloride type 3 resin, 55 parts of lead salt PH305, 10 parts of impact modifier CPE135A, 20 parts of nano-ultrafine active light calcium carbonate, 1.5 parts of AC foaming agent, 4 parts of foam regulator PA600 produced in Japan, 1.8 parts of lubricant (stearic acid 40%, PE wax 60%).

[0035] 2. PVC hollow layer: 100 parts of polyvinyl chloride type 5 resin, 10 parts of impact modifier CPE135A, 54 parts of composite stabilizer lead salt PH3054, 30 parts of nanometer ultrafine active light calcium carbonate, lubricant (stearic acid 40 %, PE wax 60%) 1.5 parts.

[0036] 3. PVC inner helical layer: same as PVC micro-foaming layer.

[0037] Such as figure 2As shown, the color ASA layer 1 is weighed according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com