Sliding sleeve for mining oil-gas well in layering manner

A technology for layered mining and oil and gas wells, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problems of low production efficiency, difficult to avoid the phenomenon of reservoir backflow, and reduced oil recovery. , to achieve the effect of preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A layered mining sliding sleeve of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

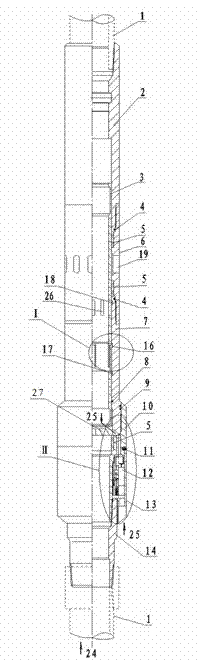

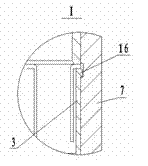

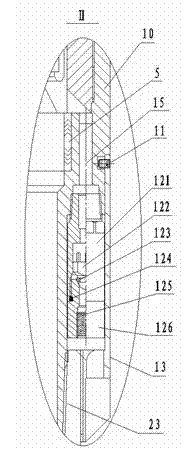

[0016] Such as figure 1 — image 3 As shown, a layered mining sliding sleeve of the present invention includes a sliding sleeve body composed of an upper joint 2, a middle joint 6, a cylinder body 7, a one-way valve joint 10 and a lower joint 14 connected by threads in sequence, and the cylinder body 7 There is a circle of first through hole 19 on the top, the sealing of the body is realized by O-ring 4 and O-ring 9, the one-way valve joint 10 and the lower joint 14 are connected by API oil pipe buckle 23 to realize sealing, the outer cylinder 13 and the one-way valve The joints 10 are connected by screws 11 , and the outer cylinder 13 is used to protect the one-way valve assembly 12 . The material of the sliding sleeve body is processed by corresponding metal suitable for the well conditions, and the sliding sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com