Two-stage and two-discharge graphite pump

A graphite and pump body technology, applied in the field of double-stage double-discharge graphite pumps, can solve the problems of difficult mechanical properties of impregnated graphite, and achieve the effects of ensuring safe and reliable long-term operation, avoiding damage to the impeller, and satisfying hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

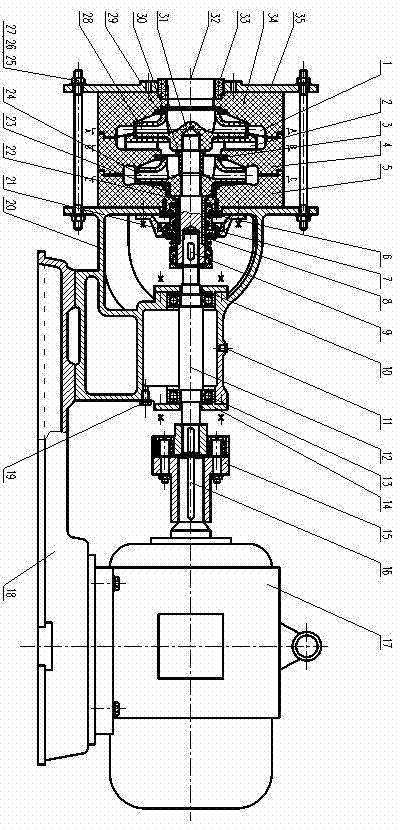

[0050] Below in conjunction with accompanying drawing, the present invention is further described:

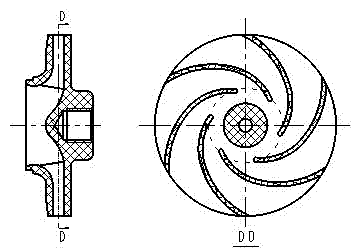

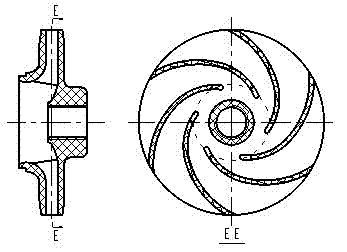

[0051] exist figure 1 Among them, the dual-stage dual-discharge graphite pump of the present invention comprises a pump cover (35), a pump body, an impeller, a bracket (20) and a rotating shaft. The pump body is divided into a front pump body (34), a middle pump body (4) and a rear pump body (5). The rotating shaft is formed by connecting the long shaft (12) and the short shaft (31). The pump adopts two-stage impellers, which are the first-stage impeller (28) and the second-stage impeller (24). The pressurized water chamber where the secondary impeller (24) is located adopts a symmetrical double discharge structure, and the pressurized water chamber is symmetrically distributed in a spiral shape. The flow parts in the pump that are in contact with the medium are all made of graphite.

[0052] The motor (17) and the bracket (20) are mounted on the base (18), and the motor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com