Temperature analyzing method for lockup clutch friction plate of hydraulic torque converter

A technology of torque converter and locking clutch, applied in the direction of friction lining, fluid transmission, belt/chain/gear, etc., to achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The hydraulic torque converter that is W305 is described in detail below in conjunction with accompanying drawing with model:

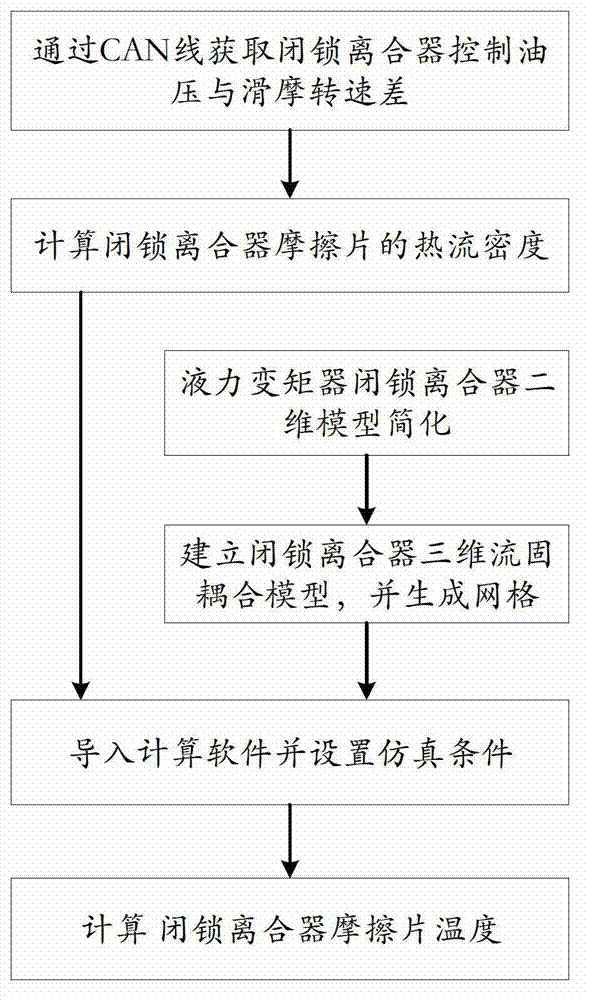

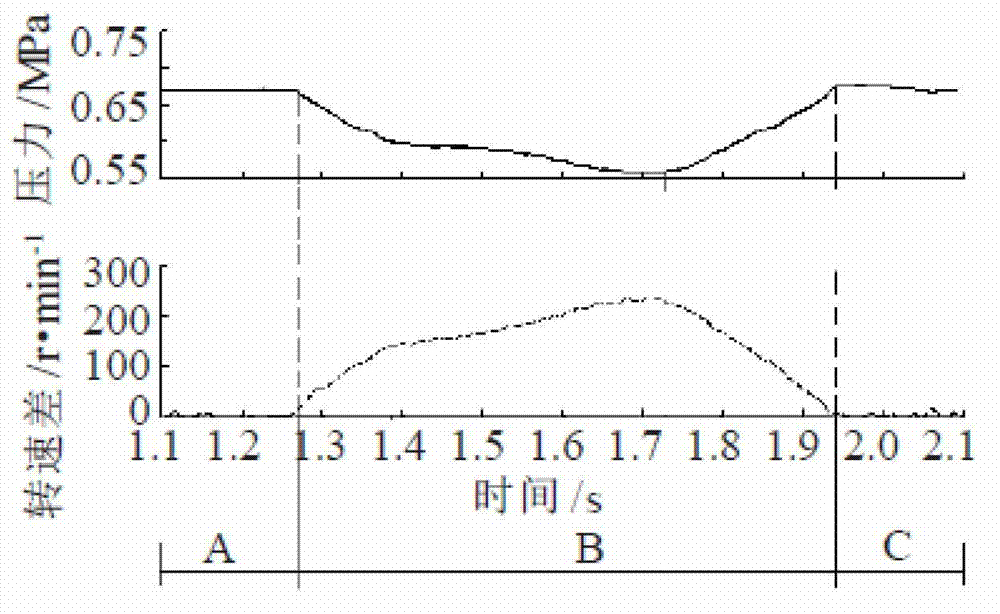

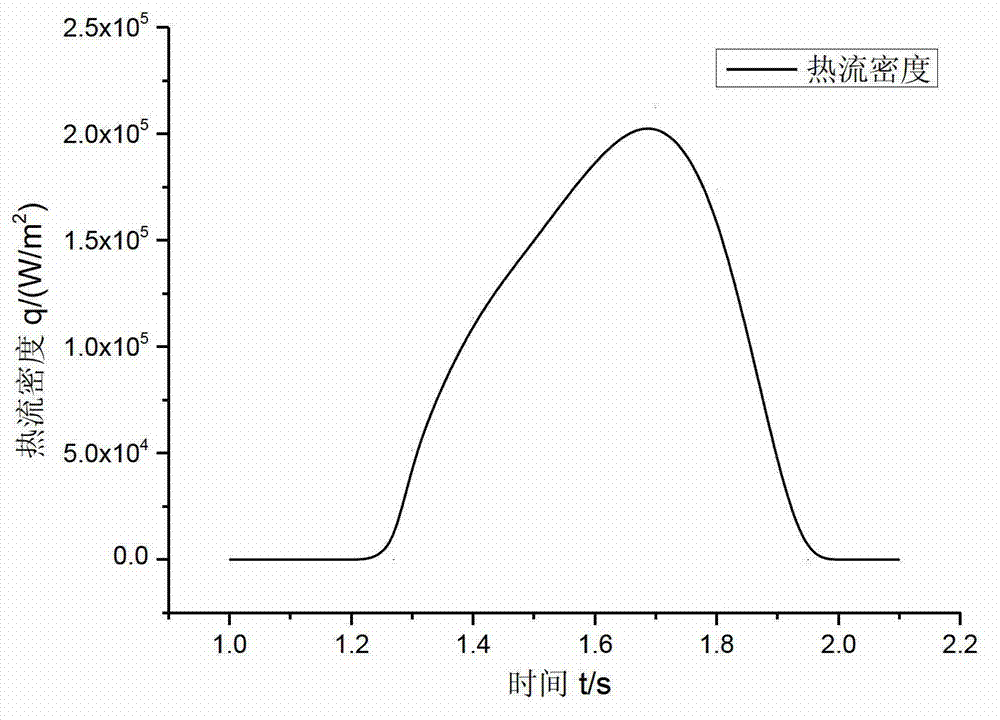

[0034] The method for analyzing the friction plate temperature of the lock-up clutch of the hydraulic torque converter according to the present invention is not dependent on external conditions, and obtains the hydraulic torque converter through the communication protocol (CAN line) between the engine electronic control unit and the transmission electronic control unit. When the lock-up clutch is combined, the control oil pressure of the friction plate and the speed difference between the main and driven plates (sliding friction speed difference), analyze and calculate the sliding work of the friction plate when the friction plate is working, and finally calculate the heat flux density; establish a hydraulic torque converter The three-dimensional fluid-solid coupling model of the lock-up clutch calculates the temperature change law and trend of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com