Antenna assembly detection method

An assembly detection and antenna technology, applied in the direction of measuring devices, measuring instruments, measuring angles, etc., can solve problems such as inability to intervene, low efficiency, time-consuming and labor-consuming measurement process, and achieve the goal of avoiding repeated calculation processes and improving assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

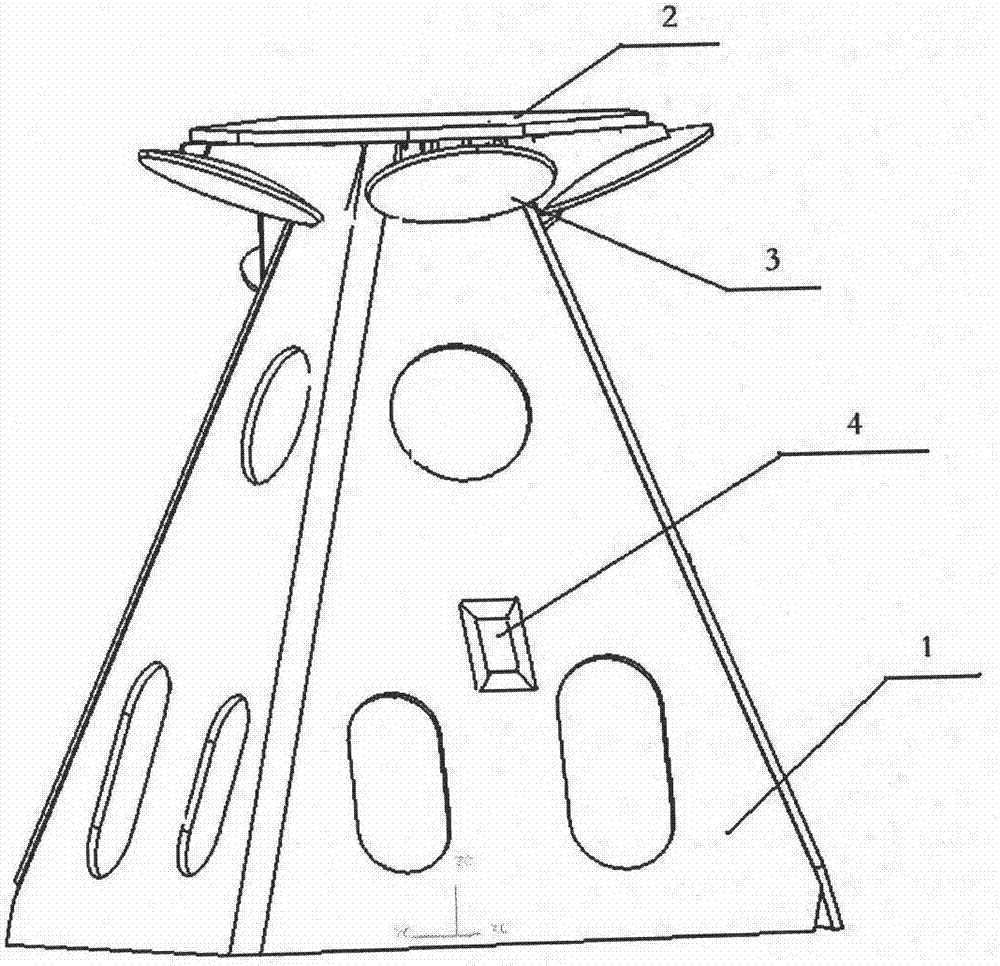

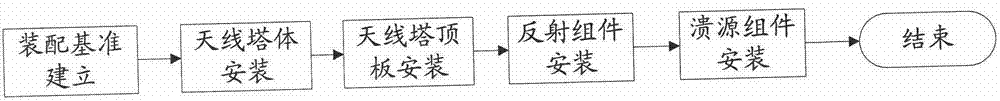

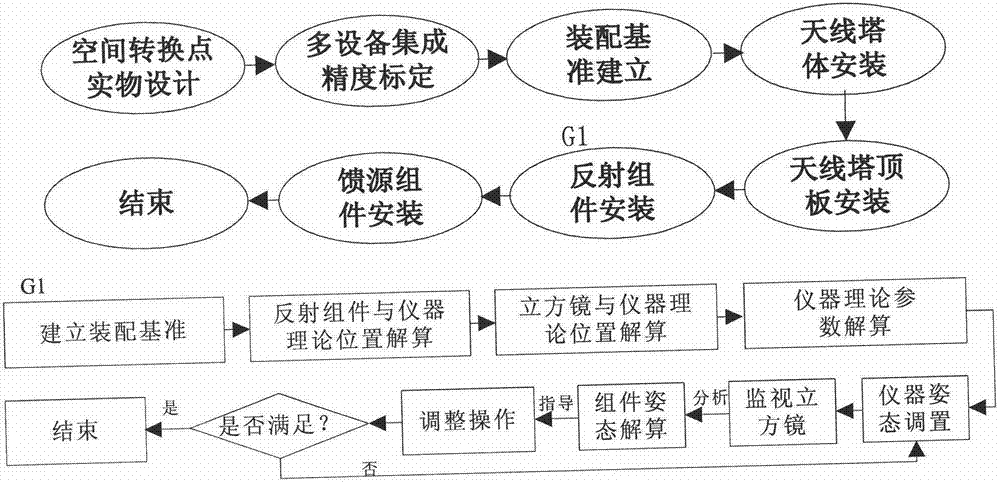

[0031] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings. An antenna assembly detection method, the detection object used in the method is as figure 1 As shown, the antenna takes the antenna tower body as the basic structure, and the antenna tower body is composed of the antenna tower body support plate 1 and the antenna tower top plate 2, and a group of secondary reflector assemblies 3 are respectively installed on each surface of the antenna tower body, and each group The corresponding feed source assembly 4 is installed under the sub-reflector assembly, and the above-mentioned parts are assembled on the assembly platform; figure 1It is given that the antenna tower body is a pentahedron, and it is also applicable to other polyhedrons. The detection system relied on by the method is a laser tracker system, a theodolite system and a laser radar system. The specific process is as follows: image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com