Liquid buoyancy weighing method for determination of aluminum and iron content in steel grit aluminum

A steel sand aluminum, weighing method technology, applied in the direction of weighing by removing certain components, material analysis by measuring buoyancy, measuring devices, etc., to achieve the effect of improved reliability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

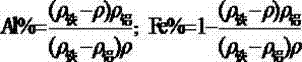

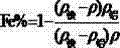

Method used

Image

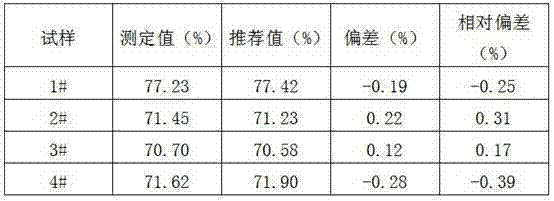

Examples

Embodiment

[0038] Embodiment: The process of the method for measuring the content of aluminum and iron in steel sand aluminum by this liquid buoyancy weighing method is as follows.

[0039] (1) Prepare steel sand aluminum samples according to Φ(25-45)mm×(25-70)mm.

[0040] (2) Select 4 representative samples, clean the surface of the samples, and mark them with a marker (1#; 2#; 3#; 4#). Weigh them separately and place them in a blast drying oven capable of precise temperature control. Put the samples into the drying oven and dry them at 105-110°C to constant weight. After drying for 15 minutes, take them out of the drying oven and place them in the drying oven. Cool naturally in the container to room temperature, weigh with a balance with a sensitivity d≤0.01g and a capacity ≥200g, and repeat the drying and weighing steps until the difference between the last two weighings does not exceed 0.1%. The measured value of the sample is m 1 (1#: 135.204g; 2#: 134.205g; 3#: 137.229g; 4#: 129....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com