Steel structure health monitoring system based on movable wireless sensor

A steel structure and sensor technology, applied in signal transmission systems, instruments, measuring devices, etc., can solve the problems of high cost and difficulty in fully displaying the safety status of bridges, so as to improve efficiency, save labor maintenance costs, and ensure safety status Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

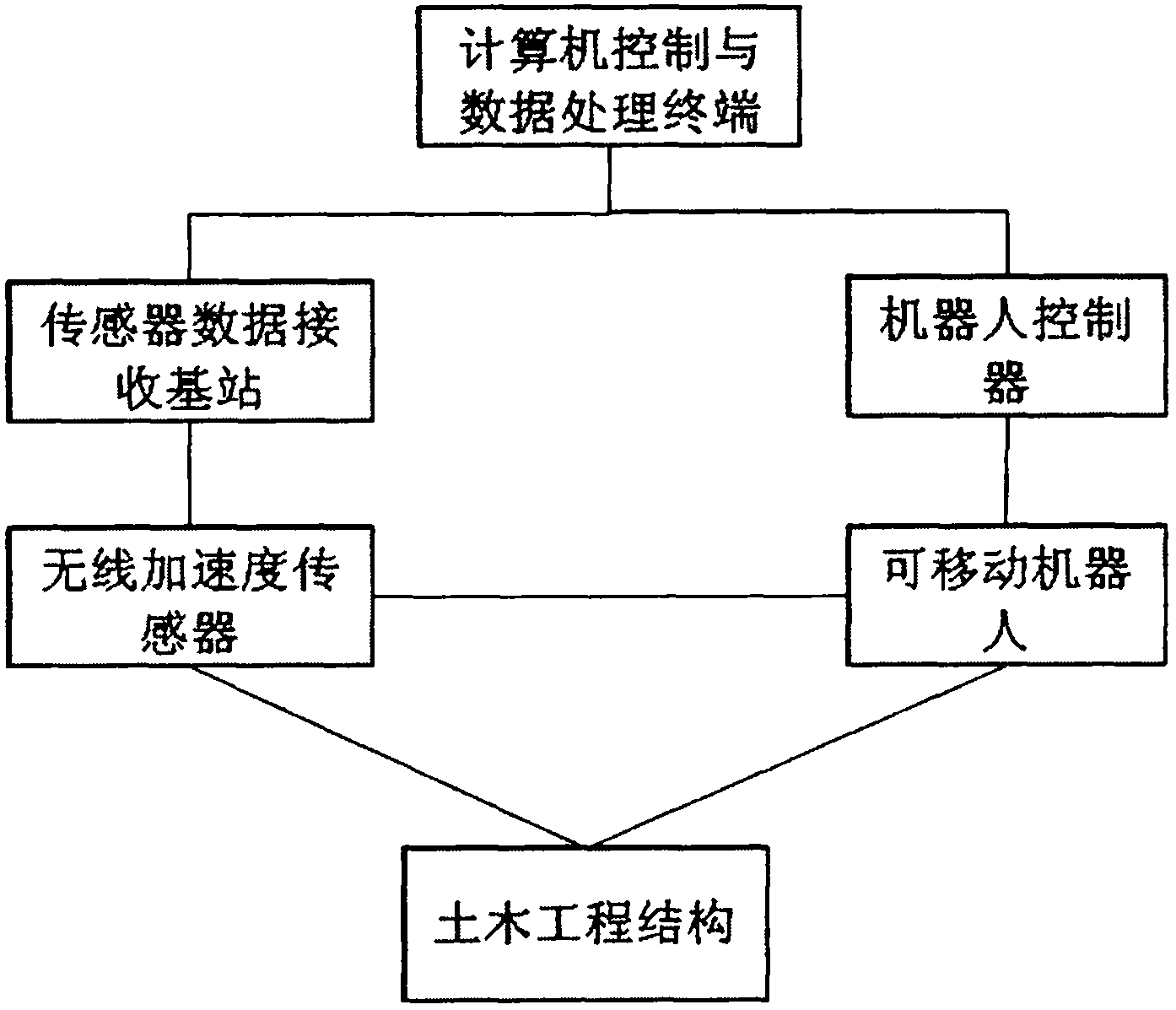

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

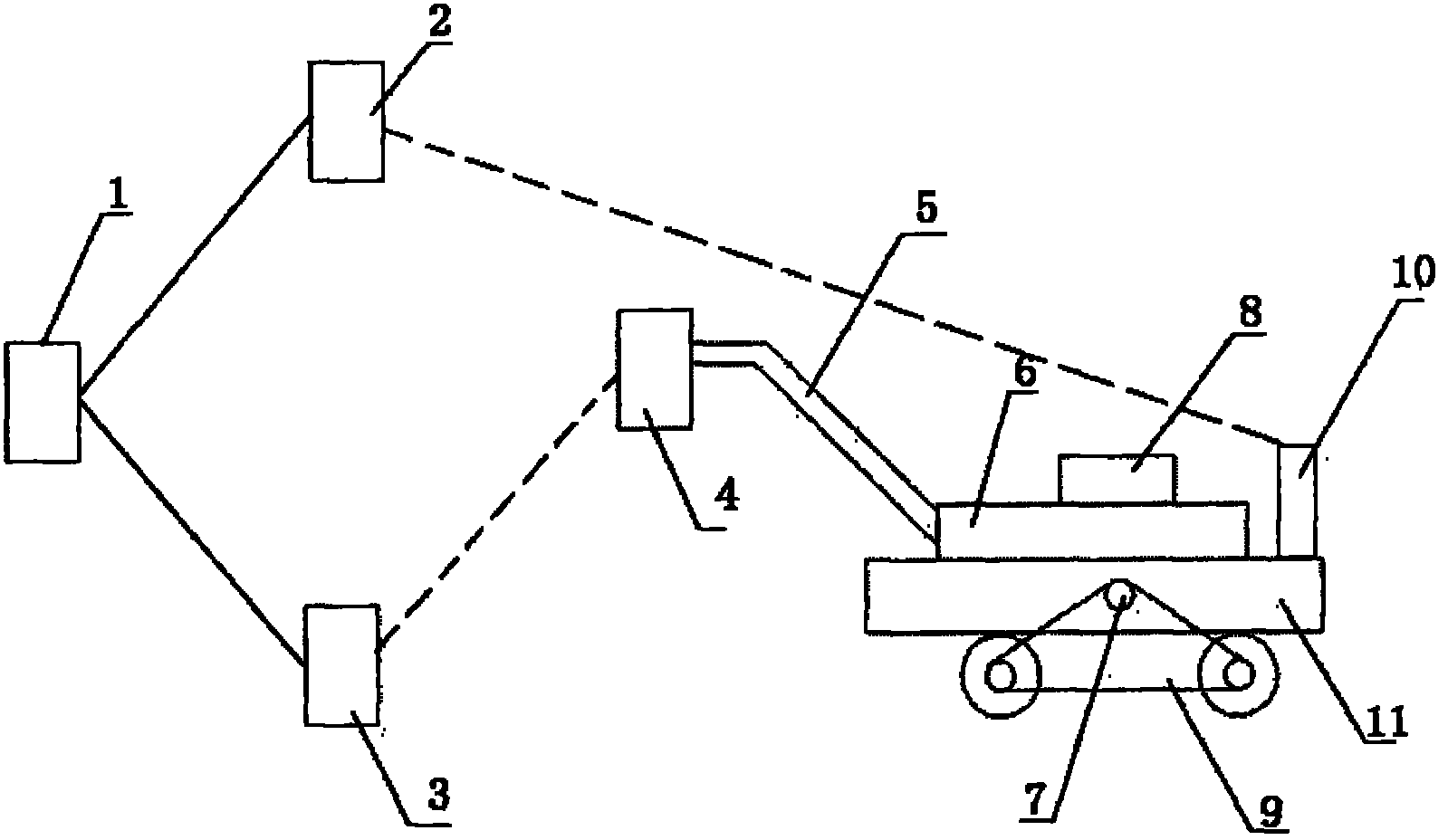

[0016] Embodiment 1: The mobile robot is the key technology of the present invention, and it is mainly divided into two parts, namely mechanical structure design and electronic system design. In terms of mechanical structure, it mainly focuses on improving the stability, safety and reliability of the robot. Proceeding from actual needs, the robot of the present invention must be lightweight, high-strength, and the adsorption force must be large enough. According to the above requirements, the main body material of the robot is mainly aluminum alloy. At the same time, in the structural design, try to reduce the amount of materials used under the premise of ensuring the strength, so as to achieve the purpose of light weight. The weight of the car body: 2.5kg. The mechanical structure of the present invention is mainly divided into two parts, a car body driven by four wheels and a multi-degree-of-freedom mechanical arm. The four-wheel drive body structure is made of 2A12 high-st...

Embodiment approach 2

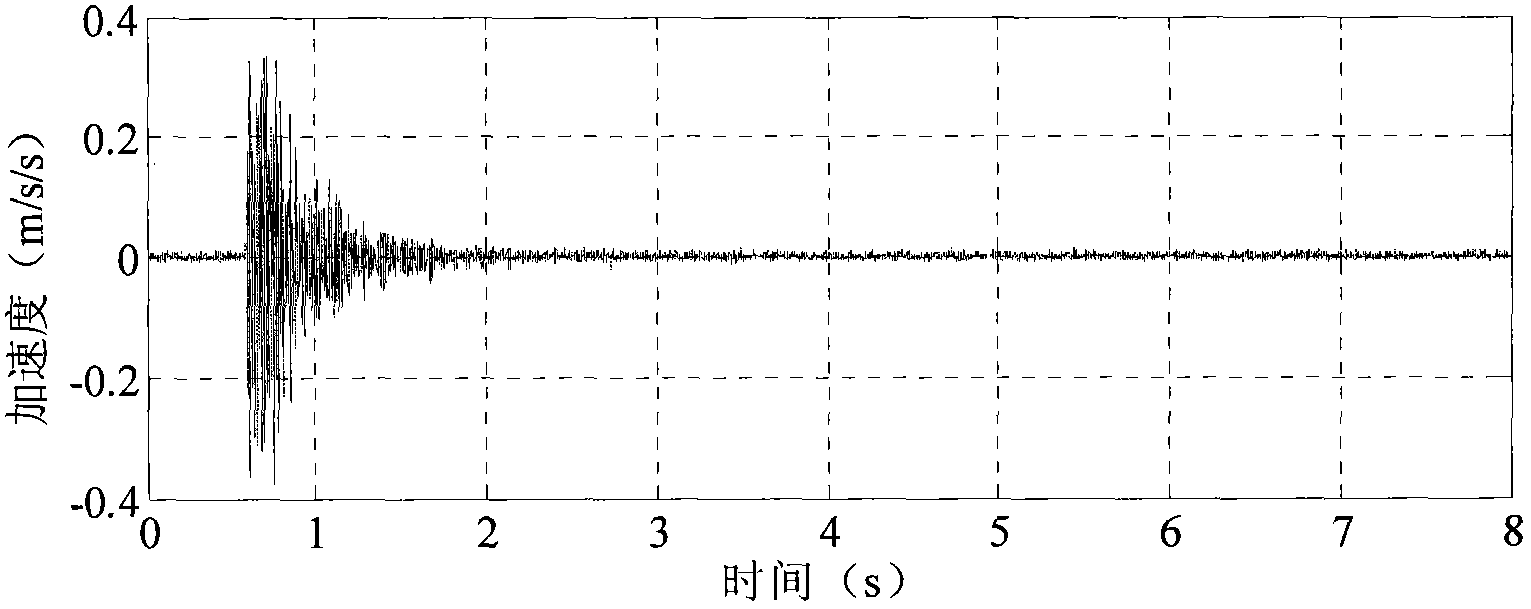

[0021] Embodiment 2: Here is an example of using the technology to carry out the vibration test of the structure, a 16-story steel frame experimental model, which uses the technology of the present invention to carry out the vibration test.

[0022]The mobile robot carries a wireless acceleration sensor and climbs on the surface of the structure. Under remote control, the wireless acceleration sensor is placed on the node of the second layer of the frame. Test the acceleration response of structural vibration. Under the impulse load excitation, the measured acceleration vibration response data are as follows: image 3 shown. After measuring the second layer, the robot picks up the sensor and continues to move the fourth and sixth layers. The measured acceleration response data are as follows: Figure 4 , Figure 5 shown. By repeating in sequence, the structural vibration response data of all floors can be realized. By adopting the technology of the invention, a single sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com