Bridge inspection machine

A technology of bridge inspection and inspection machine, applied in the direction of optical testing flaws/defects, etc., can solve the problems of limited detection range, backward detection methods, and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the examples, but the present invention is not limited to these examples.

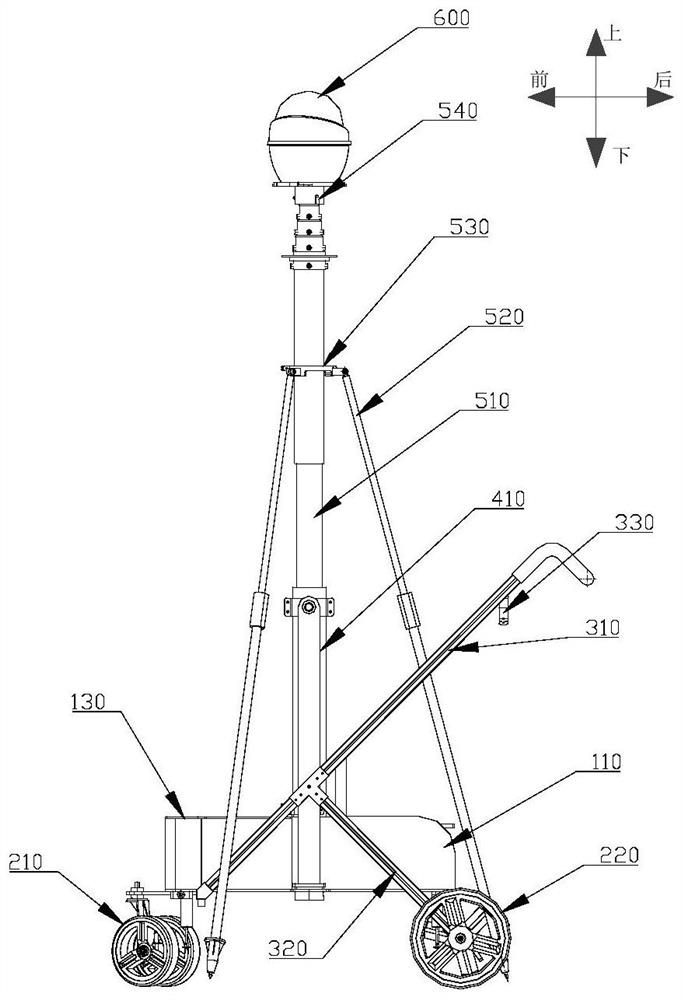

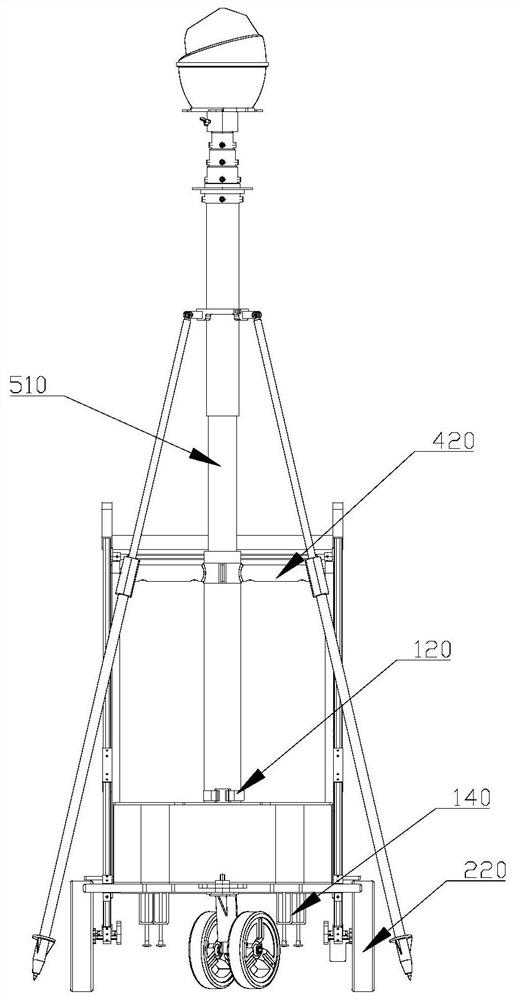

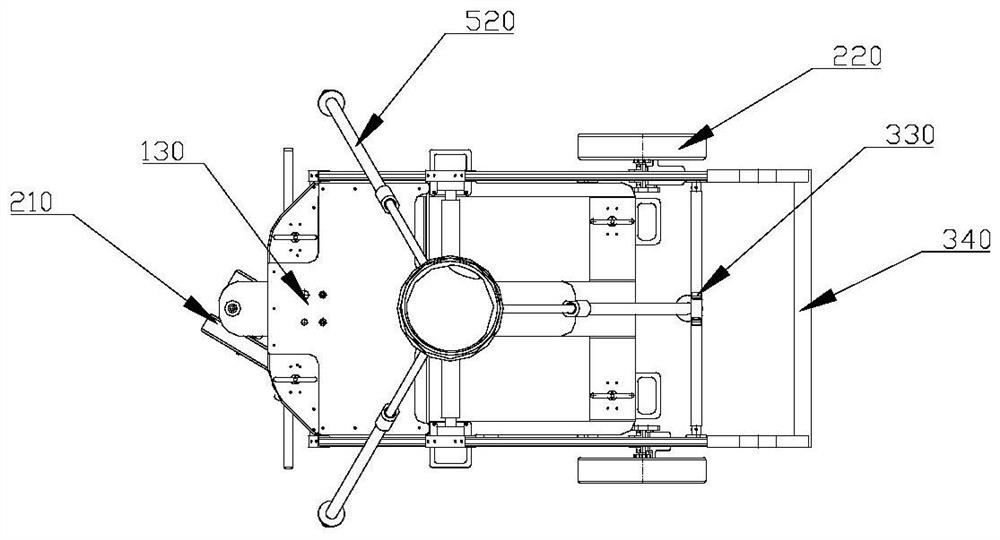

[0043] see figure 1 , The bridge detection machine provided by the present invention includes: a bridge disease detection system 600, an electrical control module, a pneumatic rod 510 and a vehicle box body 110, the bridge disease detection system 600 is installed on the top of the pneumatic rod 510, and the pneumatic The rod 510 is in control connection with the electrical control module;

[0044] The pneumatic rod 510 is suspended and rotatably installed above the vehicle box body 110;

[0045] Both ends of the pneumatic rod 510 rotate around its middle;

[0046] After the pneumatic rod 510 is rotated, the pneumatic rod 510 is suspended on the vehicle box body 110 or perpendicular to the vehicle box body 110 .

[0047] The bridge inspection machine provided by the invention is small in size, moves quickly, and is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com