Sampling, preparation and analysis management method for coal as received in thermal power plant

A management method and a technology of coal entering the factory, which are applied in the direction of sustainable manufacturing/processing, climate sustainability, energy industry, etc., can solve the problems of lagging measurement data and the inability to prevent coal entering the factory in time, so as to control production costs and save and make full use of energy and avoid the effects of artificial interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

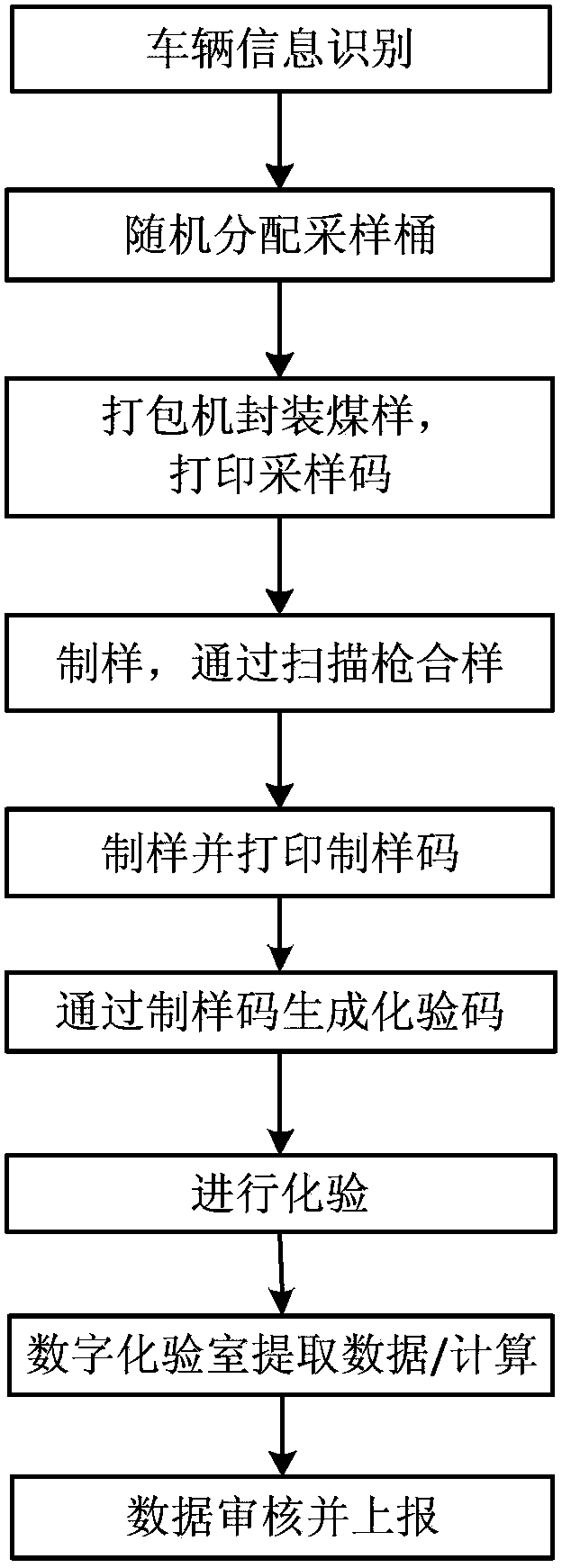

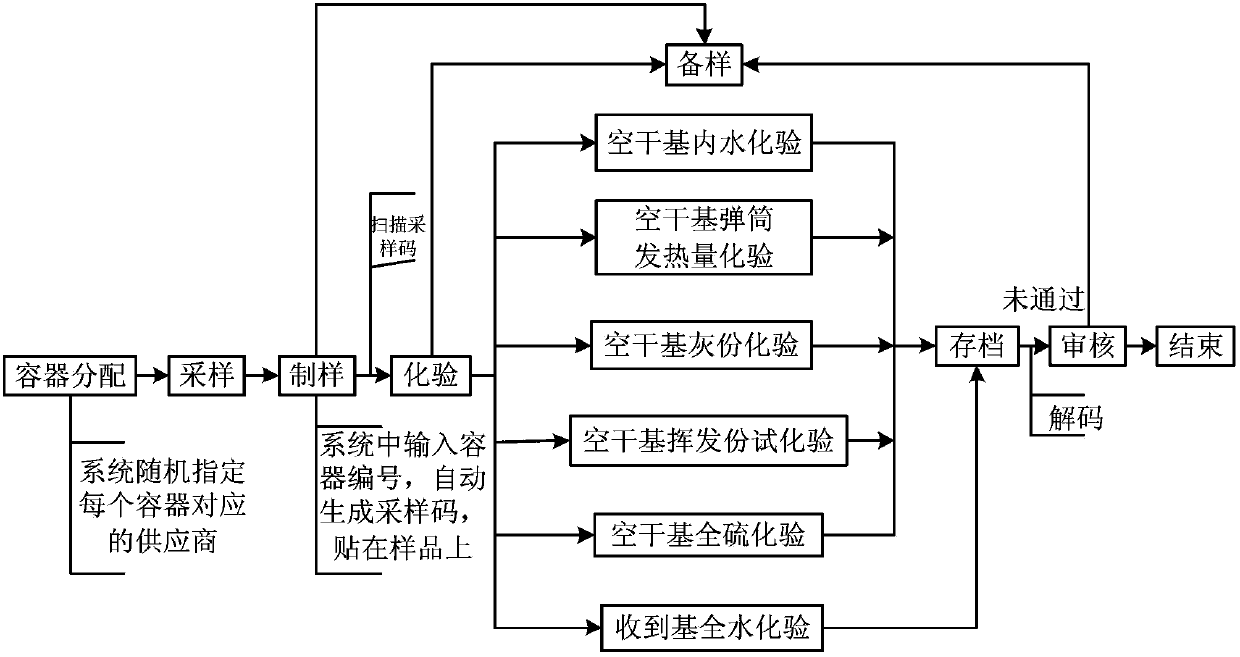

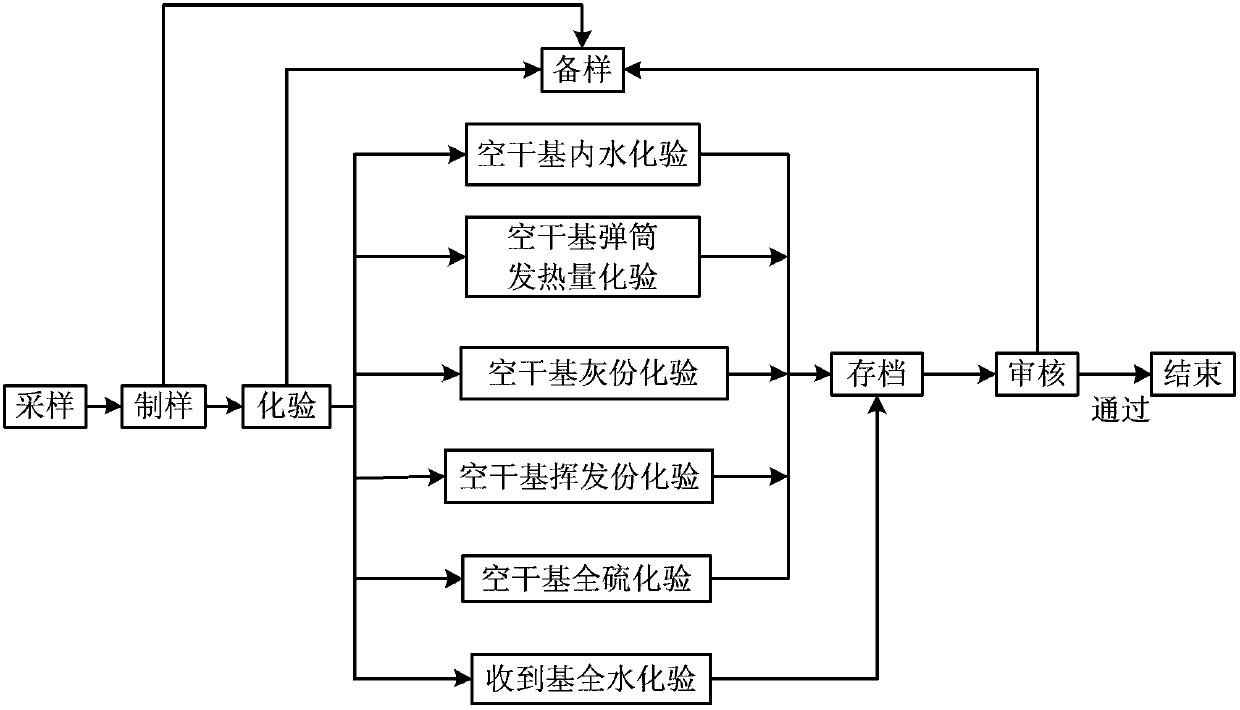

[0043] Such as Figure 1-Figure 3 , a thermal power plant incoming coal production system management method, the method comprises the following steps:

[0044] Step 1: Identify coal-carrying vehicle information;

[0045] Step 2: Assign sampling buckets;

[0046] Step 3: Print the sampling code for the packaged coal sample;

[0047] Step 4: Prepare samples to generate sample codes;

[0048] Step 5: Generate the verification code;

[0049] Step 6: Assay.

[0050] Described step 1 comprises the following steps:

[0051]Step 1-1: The coal-carrying vehicle arriving at the sampling point scans the plan card to check whether the coal-carrying vehicle violates regulations;

[0052] Step 1-2: The car number recognizer identifies the car number, scans the plan card, and records the coal-carrying vehicle and coal mine information. If it is manual sampling, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com