Foolproof monitoring method and device for automated device

An automation equipment and anti-fooling technology, which is applied in general control systems, program control, computer control, etc., can solve problems such as equipment damage, achieve the effects of reducing labor requirements, reducing costs, and avoiding defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

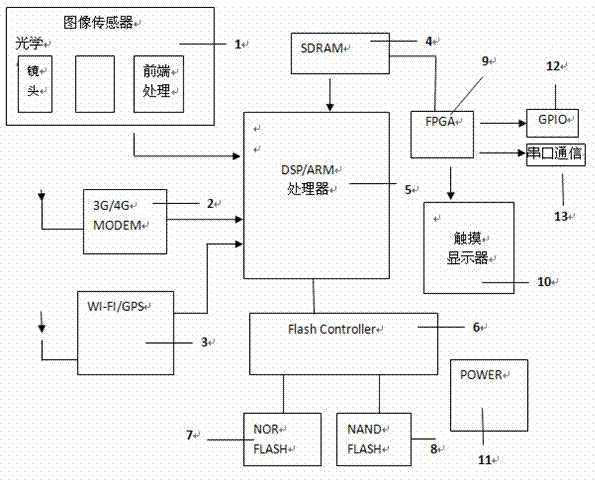

[0054] The device consists of image sensor 1, 3G / 4G modem 2, WI-FI / GPS 3, DSP / ARM processor 5, SD memory card 4, field programmable module 9, touch display 10, Flash controller 6, NOR Flash 7. Composed of NAND Flash 8, IO module 12, serial port communication module 13 and power supply 11.

[0055] Glossary:

[0056] 1. Fool Proofing, which is called Fool Proofing in English, originated from Japan, or Poka-Yoke, is a behavior restraint method for prevention and correction. It uses a restraint method to avoid mistakes, so that the operator does not need to spend attention, experience and experience. Know-how makes the right operation intuitive and error-free. In industrial design, in order to avoid the machine or personal injury caused by the user's operation error, there will be preventive measures for these possible situations, which are called fool-proofing.

[0057] 2. DSP / ARM, Digital Signal Processor / Arm.

[0058] 3. Flash, flash memory.

[0059] 4. The standard im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com