Method for designing rigidity and strength finite elements of plastic granulating mould

A finite element and granulation technology, applied in calculations, special data processing applications, instruments, etc., can solve problems such as the strength and stiffness design of plastic granulation templates for extruders that have not been seen, and achieve low production costs and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

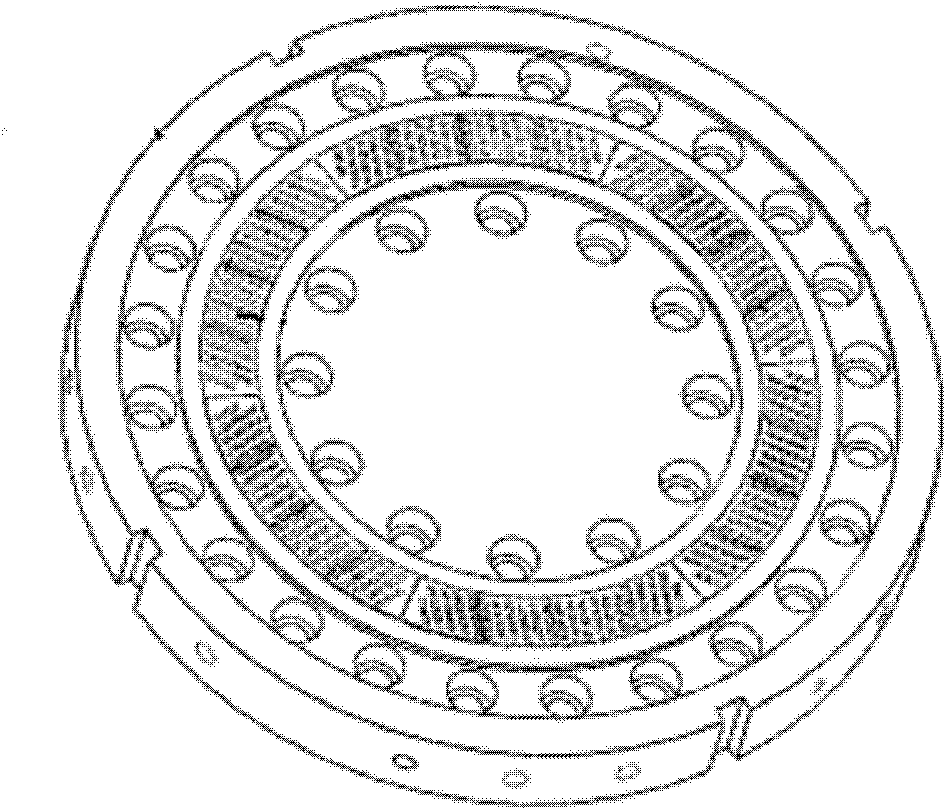

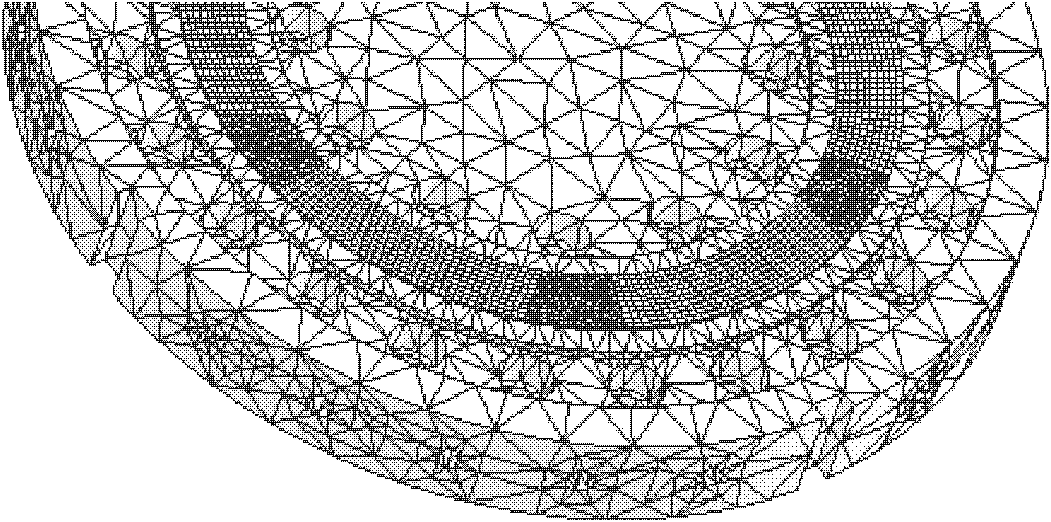

[0014] Taking the granulation formwork of a large-scale extruder of a polyolefin plant as an example below, in conjunction with the accompanying drawings, the present invention will be further described:

[0015] The main parameters of the granulation template of a large extruder in a polyolefin plant:

[0016] Geometric size of granulation template: φ1080 (outer diameter) × 130 (thickness);

[0017] Diameter of granulation belt: φ870×φ630;

[0018] Discharge hole parameters: φ2.5×20 (about 2640 holes);

[0019] Template body material: 1Cr13;

[0020] Template granulation belt material: WC carbide, thickness 4.00-4.50mm;

[0021] Granulation belt hardness: 62~65HRC

[0022] Surface flatness of granulation belt ≤0.01mm;

[0023] The parallelism between the surface of the granulation belt and the positioning reference plane of the installation notch is ≤0.02mm;

[0024] The roughness of the discharge hole is Ra0.8;

[0025] The main technical parameters of the granulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com