Cyclically liquid feeding apparatus

A liquid circulation and supply device technology, applied in cooling fluid circulation devices, household refrigeration devices, liquid level control, etc., can solve the problems of unbalance, large liquid level fluctuations, and high prices, and achieve easy temperature adjustment and elimination of liquid level. The effect of change, cheap installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred Mode for Carrying Out the Invention

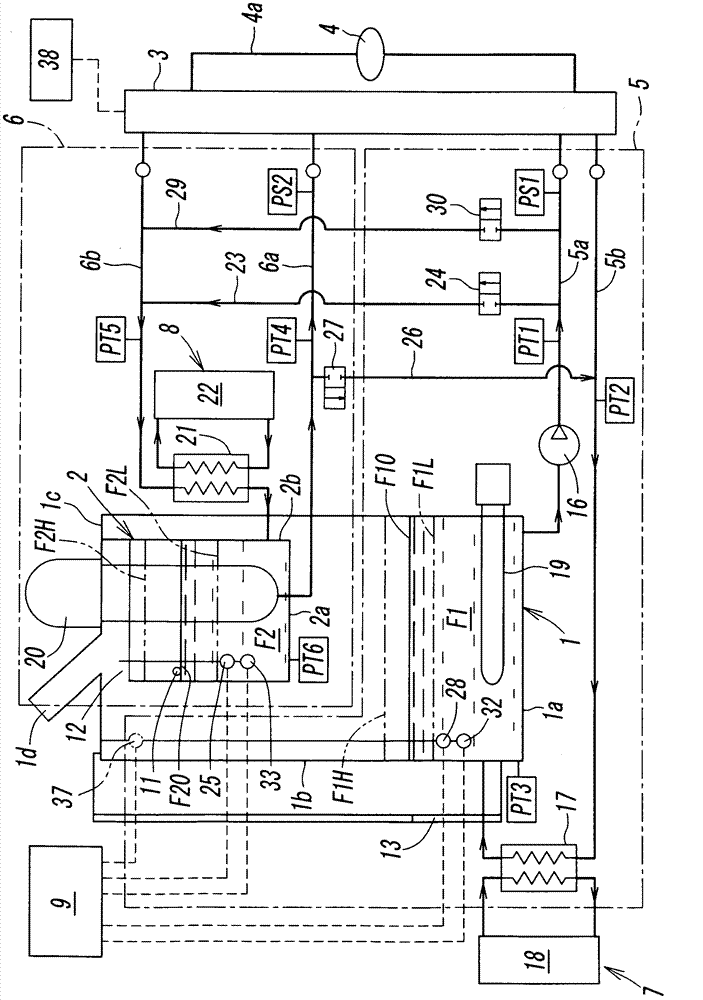

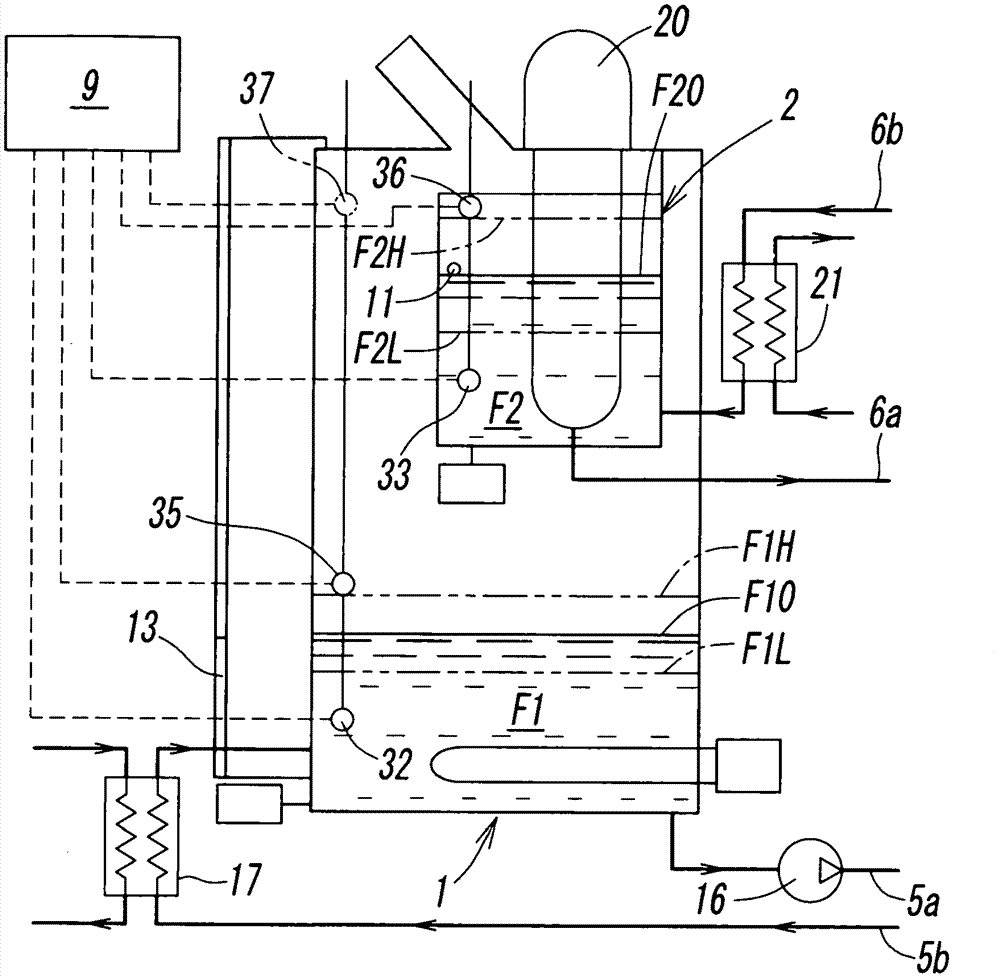

[0022] figure 1 A configuration diagram showing a first embodiment of the liquid circulation supply device according to the present invention. This liquid circulation supply device has a large-capacity outer container 1, a small-capacity inner container 2, a valve device 3, a liquid circulation path 5 for the outer container, a liquid circulation path 6 for the inner container, a first temperature adjustment device 7, a second The temperature adjusting device 8 and the control device 9, the above-mentioned large-capacity external container 1 accommodates the first liquid F1, and the above-mentioned small-capacity internal container 2 is installed inside the external container 1, and contains a second fluid having a temperature different from that of the above-mentioned first liquid F1. Two liquids F2, the valve device 3 supplies the first liquid F1 and the second liquid F2 individually or mixed to the load 4, and the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com