Filter loading broadband three-gap coupling output cavity structure

A technology of coupling output and output cavity, applied in the microwave field, can solve the problems of lengthening the interaction distance, increasing the weight of the focusing system, and the application of unfavorable interaction klystrons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to help a better understanding of the present invention, specific embodiments of the present invention will be described below with reference to the accompanying drawings.

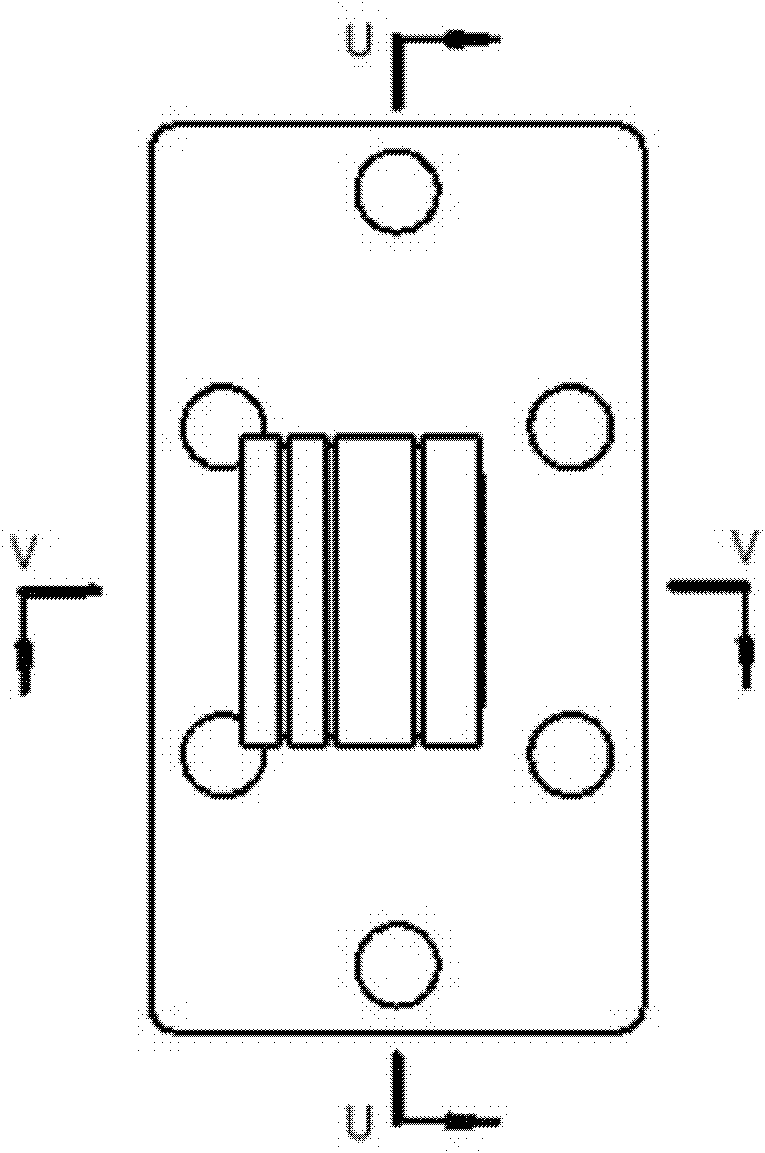

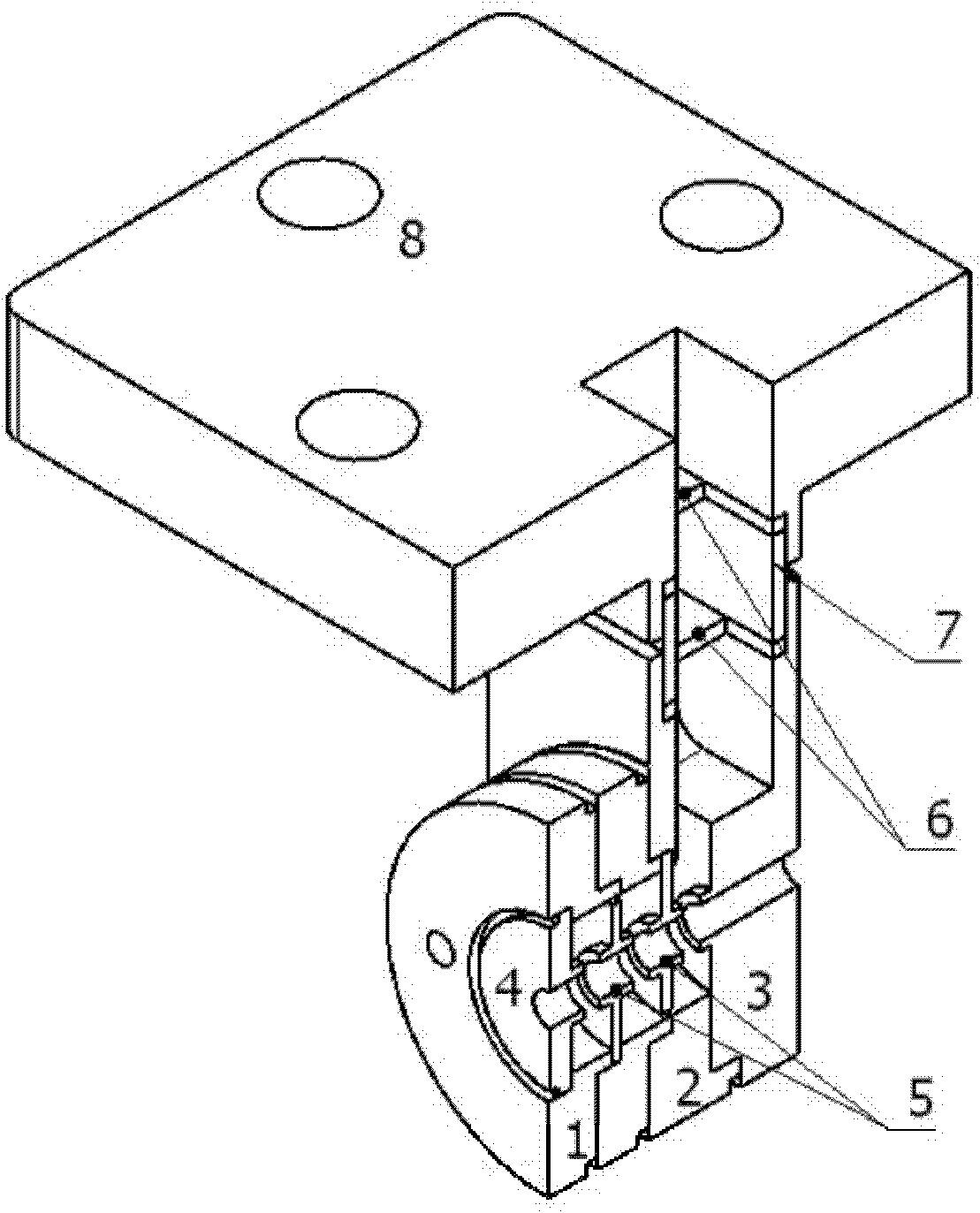

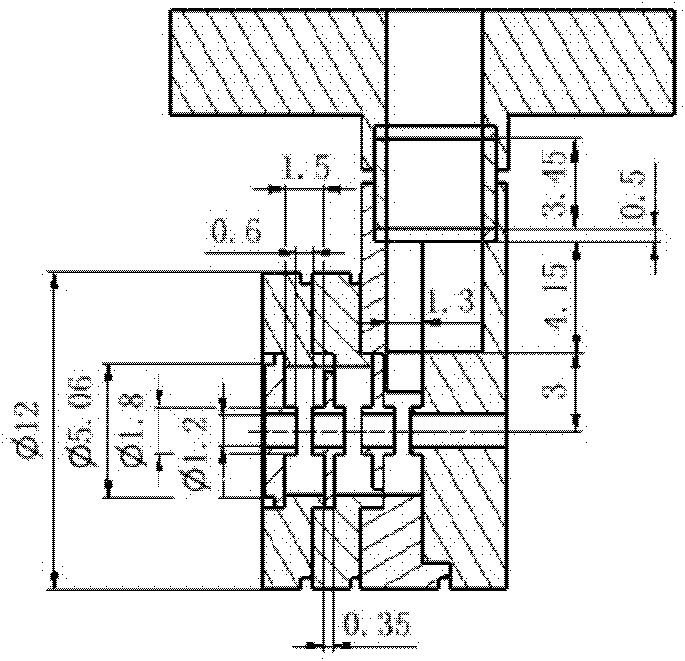

[0033] Referring to Fig. 1-Fig. 10, a filter loading broadband triple-gap coupling output cavity structure of the present invention includes cavity 1, output cavity waveguide 1, output cavity waveguide 2 3, cavity cover 4, and cavity plate 5 , filter diaphragm 6, output waveguide section 7 and output waveguide flange 8. The cavity 1 cooperates with the clasp structure of the cavity plate 5 to form a small-sized coupling groove structure; cavity 1, output cavity waveguide 1, output cavity waveguide 2, cavity cover 4, output waveguide section 7 and output waveguide method Welding is carried out by external cutting groove between the blues 8; the cavity 1, the output cavity waveguide 2, the output cavity waveguide 2 3, the cavity cover 4 and the cavity sheet 5 have a central axis, the cavity 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com