Integrated circuit plastic packaging mold for preventing horizontal overflowed material at cored hole

An integrated circuit and plastic packaging technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of increased thickness of horizontal flash, difficult removal, large spacing, etc., to achieve the effect of convenient removal and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

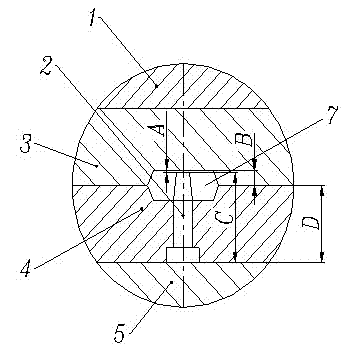

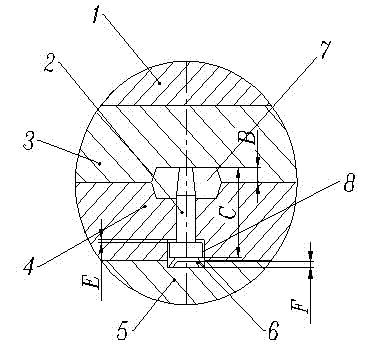

[0013] This example figure 2 As shown, it includes an upper insert seat 1, a lower insert seat 5, an upper forming insert 3 and a lower forming insert 4 and a core 2 which are superimposed between the upper and lower insert seats, the upper forming insert 3 and the lower A core hole 7 is provided in the center of the contact of the molding insert 4, and a stepped through hole 8 is provided on the lower molding insert 4. The core 2 is located in the stepped through hole 8. The bottom surface of the larger diameter end of the stepped through hole 8 is There is a gap between the corresponding surfaces of the core end at the larger end, and a spring 6 is arranged between the bottom surface of the core 2 and the lower insert seat 5 to realize the elastic extrusion of the upper end surface of the core 2 on the upper molding insert of the core hole. Pieces on 3 sides. The preferred form of the spring 6 is a butterfly spring. There is also a gap between the larger diameter end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com