Lead storage battery

A lead-acid battery and single-battery technology, applied in lead-acid battery, lead-acid battery construction, battery and other directions, can solve the problems of deep discharge depth, capacity reduction, battery scrapping, etc. Effects of stress corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

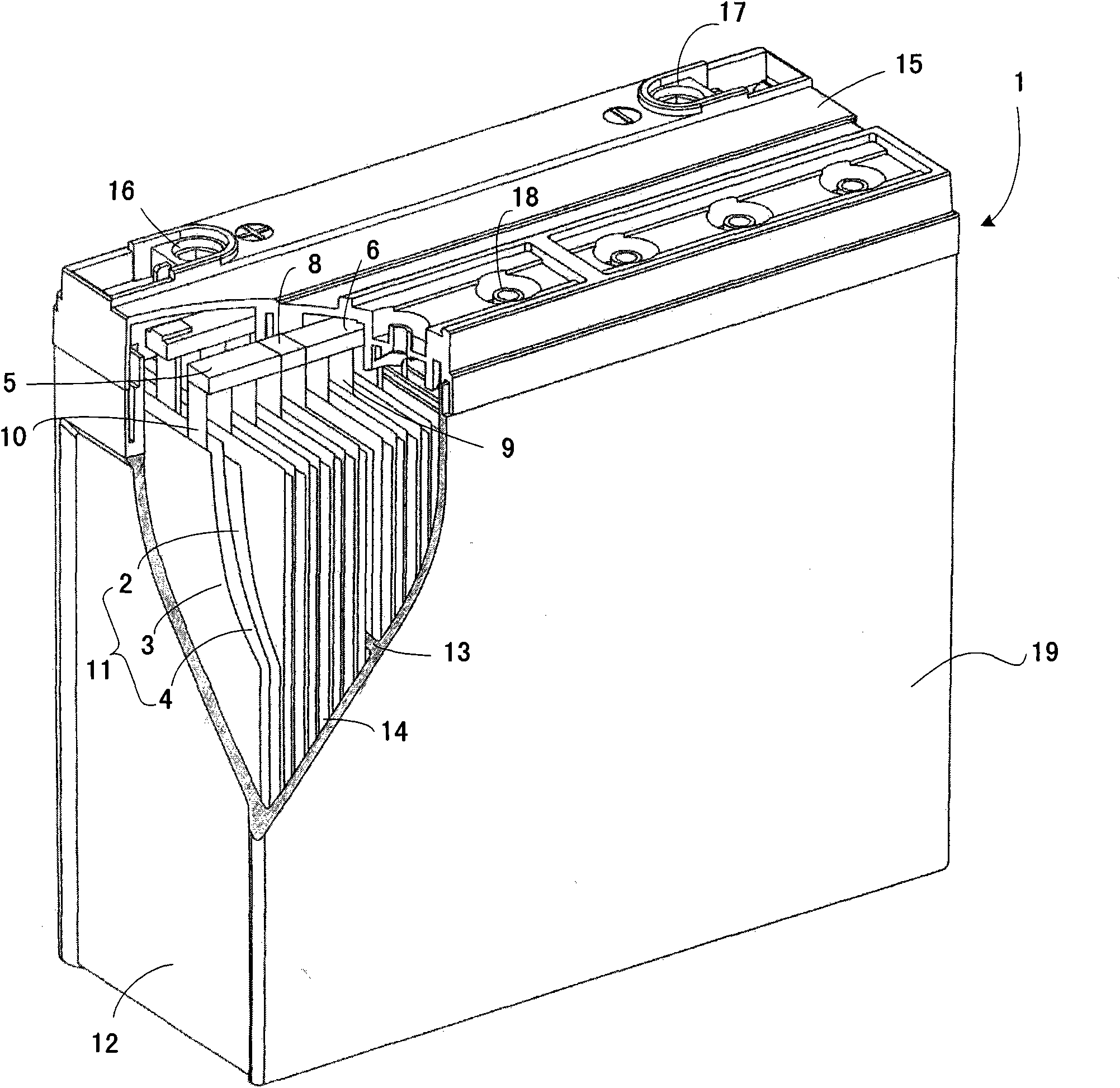

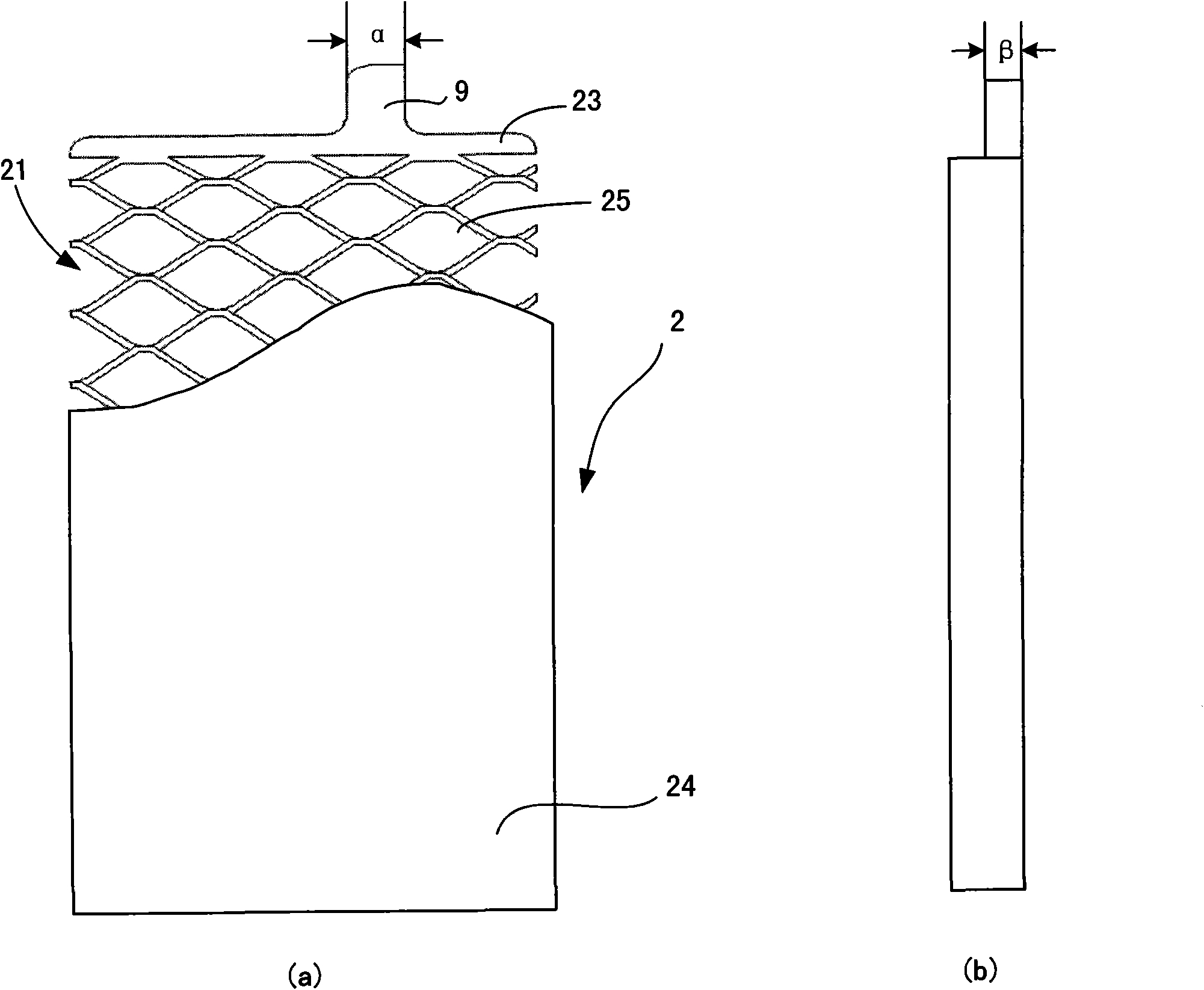

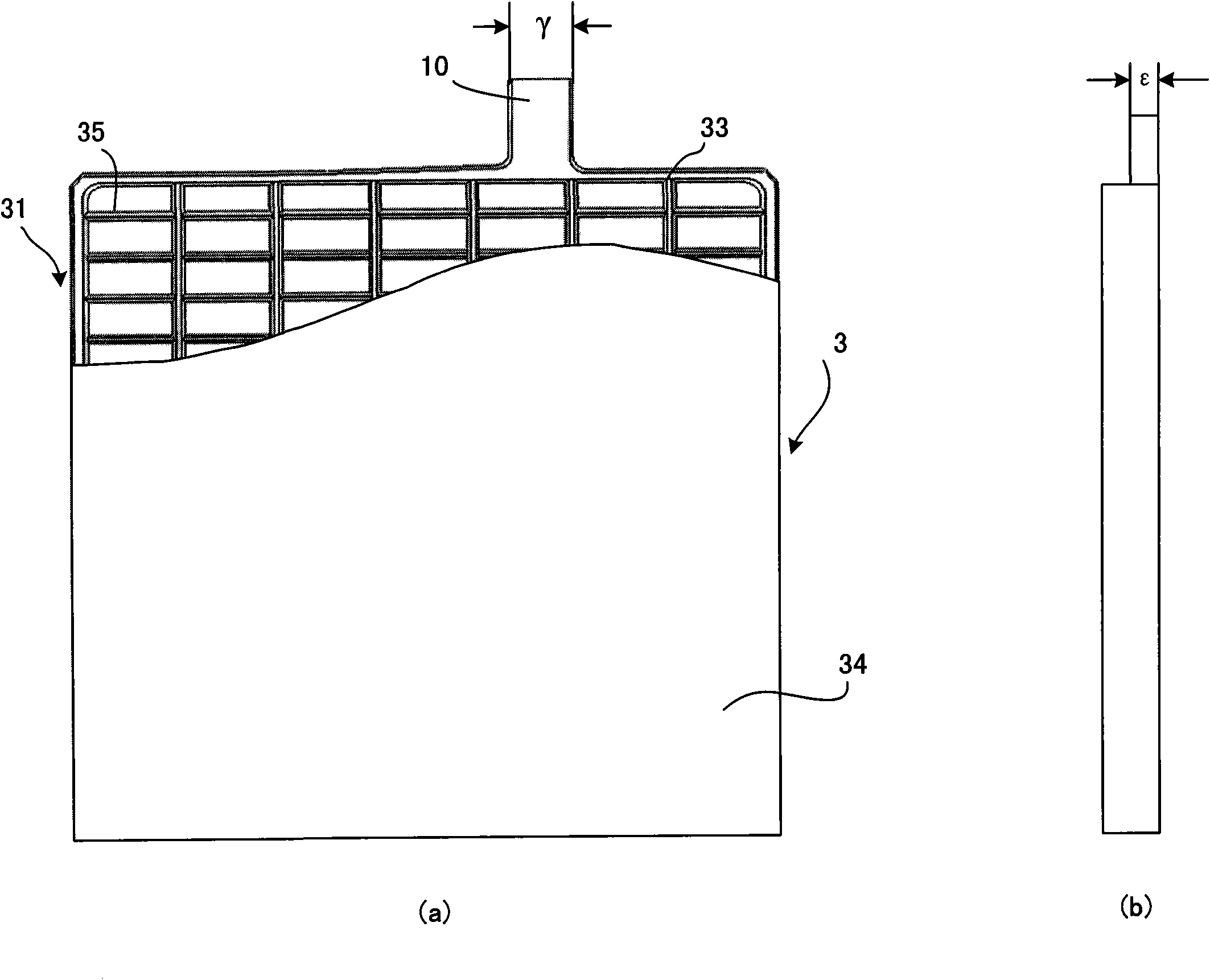

[0081] The lead storage battery 1 of Embodiment 1 has a plurality of unit cells 12, and each unit cell 12 has a pole plate group 11, an electrolyte solution (not shown) and a unit cell chamber 14, and the above-mentioned pole plate group 11 is immersed in The state of the electrolyte solution is accommodated in the above-mentioned single cell chamber 14, and the above-mentioned plate group 11 is formed by alternately arranging a plurality of positive plates 2 and a plurality of negative plates 3 with separators 4 interposed therebetween. A positive electrode current collector and a positive electrode active material layer held by the positive electrode current collector, each negative plate includes a negative electrode current collector with tabs and a negative electrode active material layer held by the above negative electrode current collector, characterized in that, The positive bus bar of the positive plate and the negative bus bar of the negative plate of each single bat...

Embodiment approach 2

[0084] The lead storage battery 1 of Embodiment 2 is based on the lead storage battery 1 of Embodiment 1, further setting the thickness of the tabs of each of the above-mentioned positive plates to be smaller than the thickness of the tabs of the above-mentioned negative plates, or the thickness of the above-mentioned multiple positive plates. The total thickness of the tabs is less than the total thickness of the tabs of the above-mentioned multiple negative plates, wherein the thickness of the tabs of each of the above-mentioned positive plates is 1.0-2.0 mm, preferably 1.2-1.8 mm; the tab of each of the above-mentioned negative plates The thickness is 1.2-2.5 mm, preferably 1.3-2.0 mm.

[0085] According to the final technical effect to be achieved, other constituent elements can be appropriately selected from the foregoing detailed description.

Embodiment approach 3

[0087] The lead storage battery 1 of Embodiment 3 is based on the lead storage battery 1 of Embodiment 1, and further assumes that the above-mentioned positive electrode current collector is an expanded mesh grid made by a reciprocating cutting method, so that the tortuosity T of the grid is / W is in the range of 1.60 to 1.80, and the negative electrode current collector is a grid made by casting. Moreover, it is preferable to set the ratio P / T which shows the paste overfill rate on the said expanded-grid to the range of 1.14-1.30.

[0088] According to the final technical effect to be achieved, other constituent elements can be appropriately selected from the foregoing detailed description.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com