Electric servo device and brake device employing same

A booster device, electric technology, applied in the direction of braking transmission device, using electric device, using electromagnetic means, etc., can solve the problem of loss of load and other problems, achieve the effect of reducing the installation space, reducing the number of parts, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, modes for implementing the present invention will be described using the drawings.

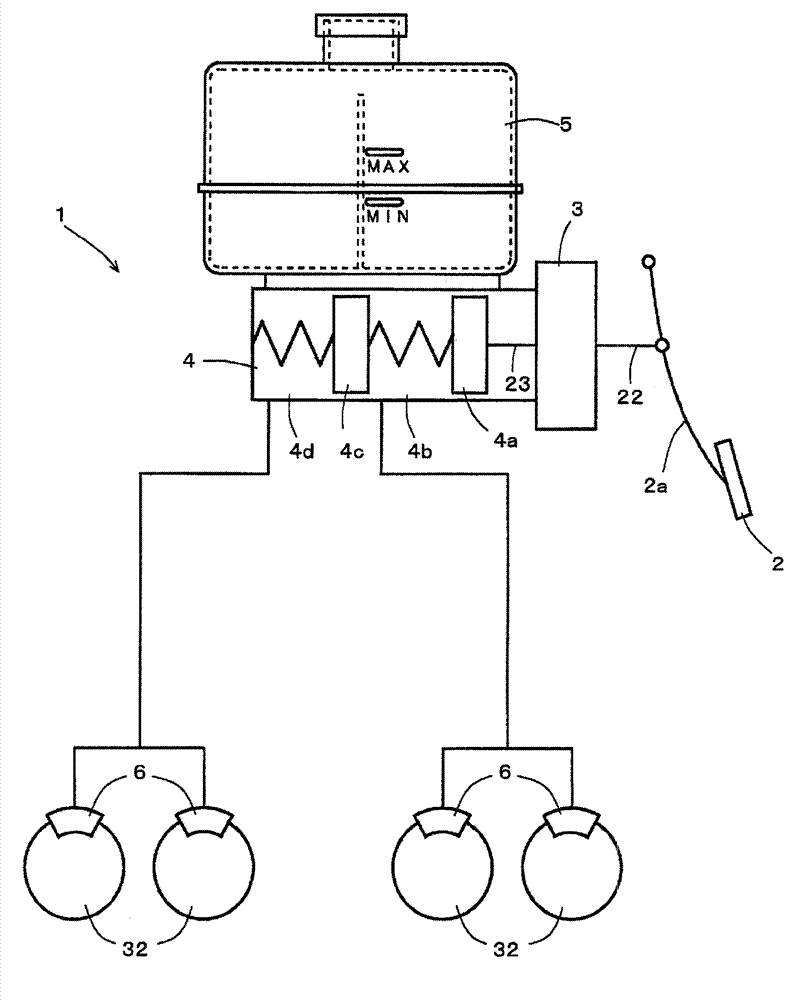

[0026] figure 1 It is a figure which schematically shows the braking device which has an example of embodiment of the electric booster of this invention.

[0027] Such as figure 1 As shown, the brake device 1 of this example is basically the same as a conventionally known general two-system brake device. That is, the brake device 1 includes a brake pedal 2 , an electric booster 3 , a tandem master cylinder 4 , a storage tank 5 , and a brake cylinder 6 .

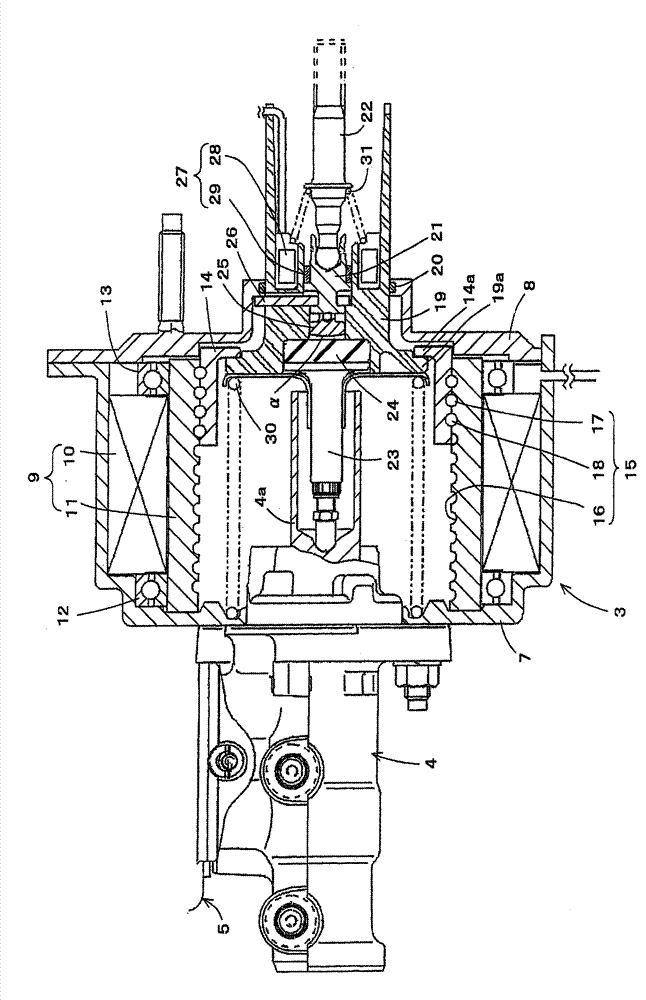

[0028] Such as figure 2 As shown, the electric booster 3 of this example has a front case 7 and a rear case 8 connected to each other. An electric motor 9 is arranged inside the front case 7 . The electric motor 9 has a stator 10 and a rotor 11, wherein the stator 10 is an annular magnetic force generating part composed of a coil fixedly supported on the front housing 7, and the rotor 11 passes through the inner circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com