Melon planing machine

A technology of melon machine and frame, which is applied in the fields of vegetable or fruit peeling, food science, application, etc. It can solve the problems of high cost, heavy labor, and complicated fixed mechanism, so as to improve production efficiency and save labor , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

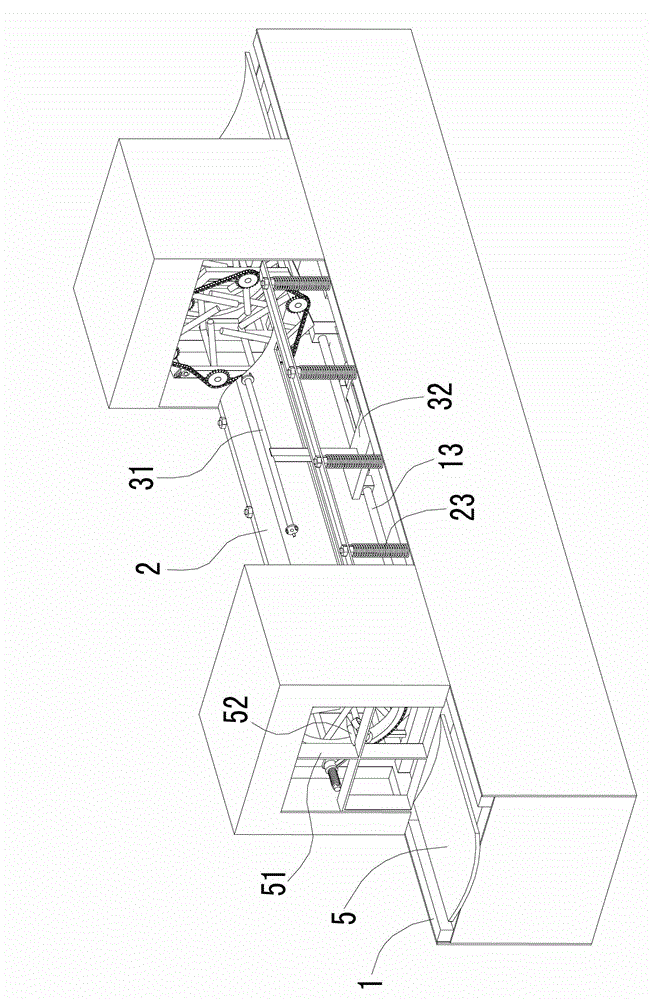

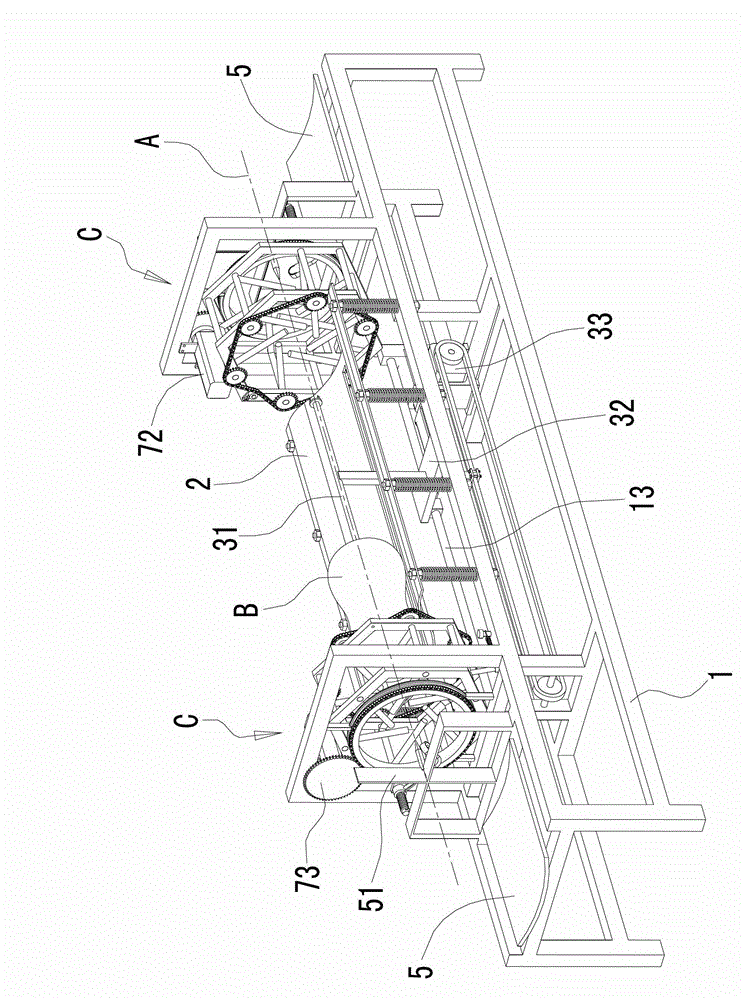

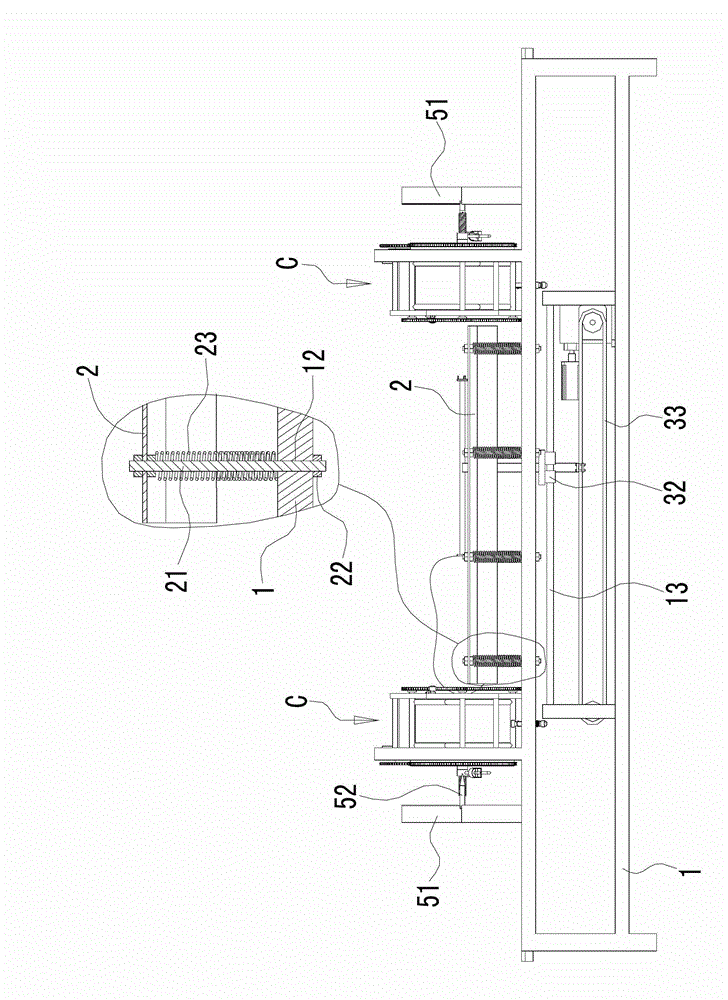

[0034] Such as Figure 1 to Figure 10 Shown, a kind of planing melon machine comprises frame 1, supporting plate 2, pushing mechanism, planing mechanism and receiving plate 5, and frame 1 has a feed path A, and pushing mechanism drives supporting plate 2 The melons and fruits B on the top enter the material receiving plate 5 through the planing mechanism along the feed path A, and the planing mechanism includes a planer 41;

[0035] The frame 1 is provided with a clamping device, and the pushing mechanism drives the fruits B on the supporting plate 2 to pass through the clamping device and the planing mechanism sequentially along the processing path A. The clamping device includes a frame 61 and at least three The clamping member 62, the frame 61 is installed on the frame 1, and the feeding path A passes through the hollow of the fra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap