Multipurpose waveband pressure wave device for metal honeycomb carrier

A metal honeycomb carrier and wave band technology, which is applied in the field of metal honeycomb carrier processing equipment, can solve the problems of unsatisfactory, single pressing structure, unsatisfactory pressure wave height, etc., to ensure product quality, reduce waste amount, and reasonable structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

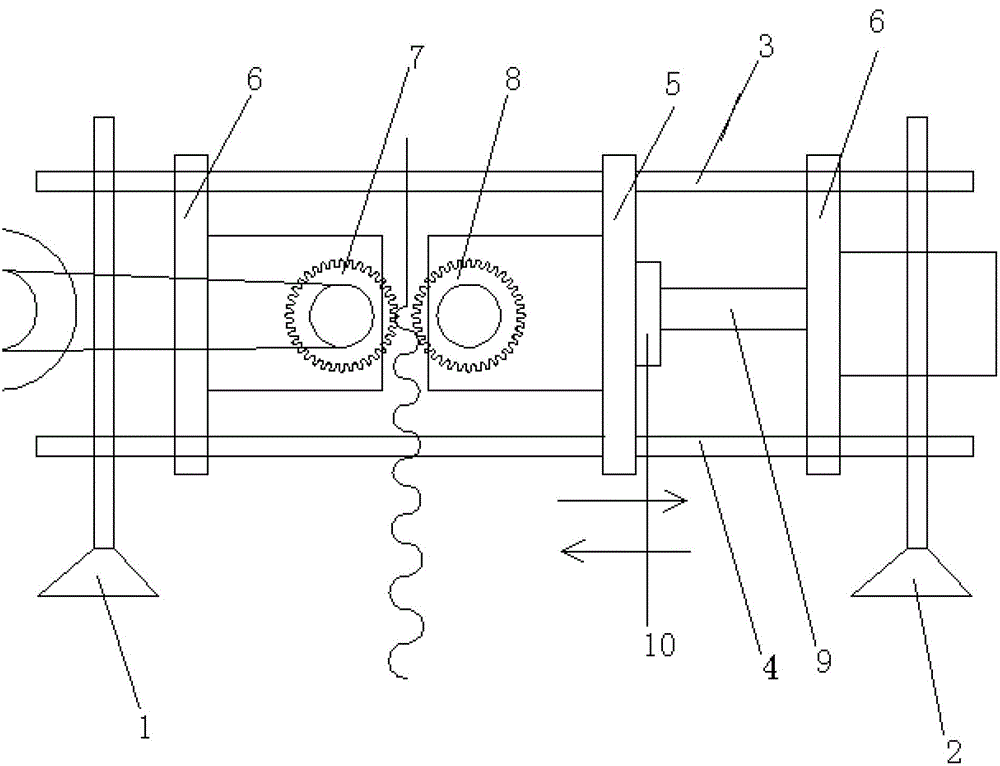

[0012] Referring to the accompanying drawings, a multi-purpose metal honeycomb carrier corrugated wave compression device includes left and right fixing frames 1, 2, and upper and lower guide rods 3, 4 are respectively arranged between the left and right fixing frames 1, 2 , between the upper and lower guide rods 3,4 is slidingly fitted with a slide plate 5, a fixed plate is fixedly installed between the slide plate 5 and the left and right fixed brackets 1, 2 respectively, and the fixed plate 6 on the left side and the slide plate 5 are respectively rotated and installed There are corresponding active pressure wave rollers 7 and driven pressure wave rollers 8. The rotation of the active pressure wave rollers 7 is driven by a motor, and the movement of the driven pressure wave rollers 8 is driven by a motor and a screw. The screw mandrel 9 is equipped with The screw nut 10 is fixedly connected to the outside of the slide plate 5; the teeth of the active pressure wave roller 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com