Assembling adhesive-dispensing device applied to micron order microtube and micropore

A dispensing device and micro-pipe technology, which is applied to the surface coating liquid device, metal processing, metal processing equipment, etc., can solve the problems that cannot meet the assembly of micron-sized parts, large size, and large dispensing volume. Achieve the effect of convenient and efficient assembly and dispensing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

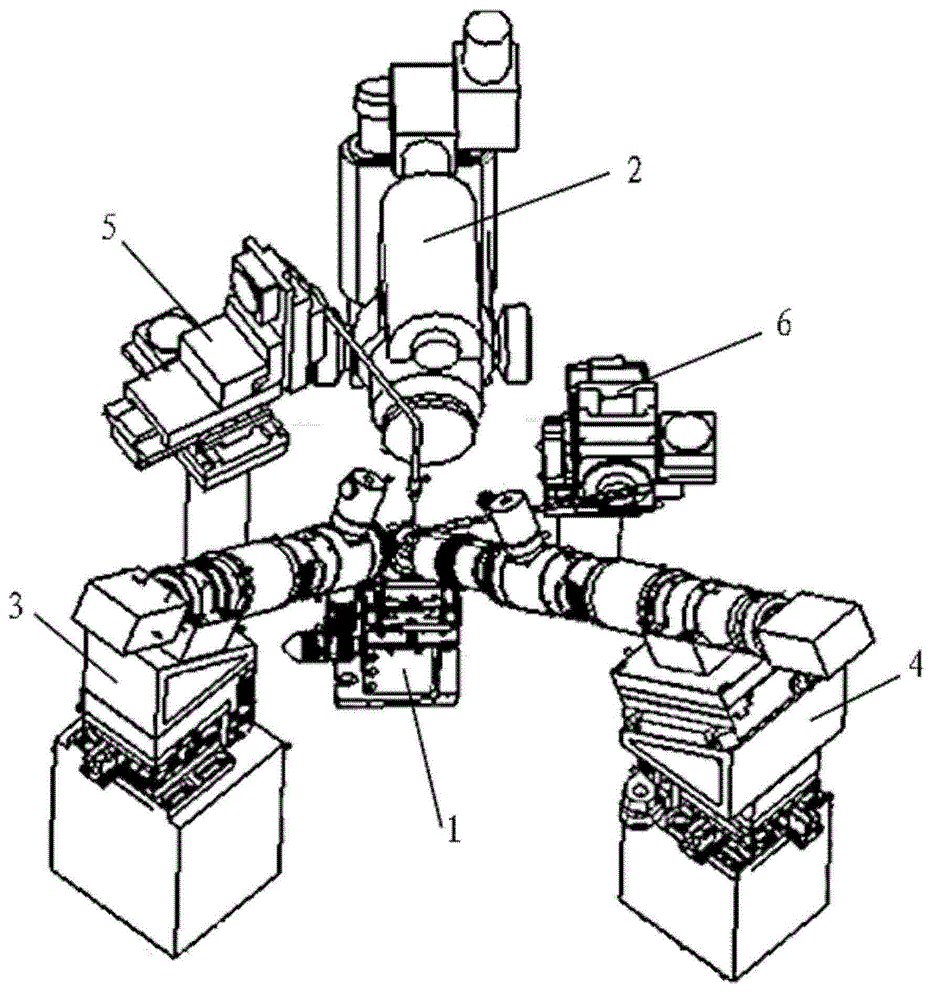

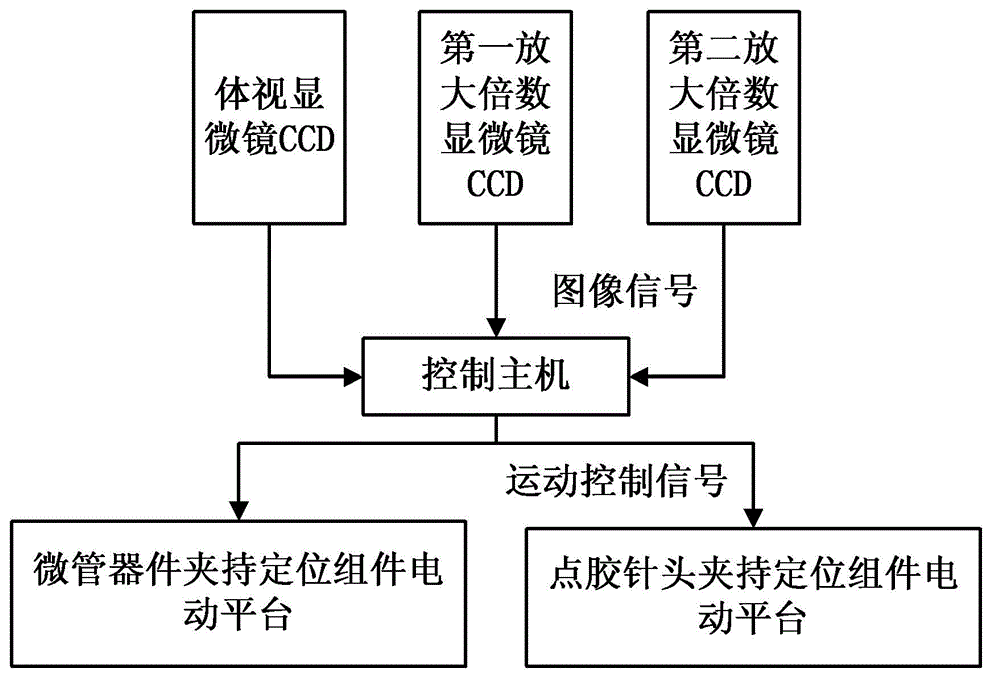

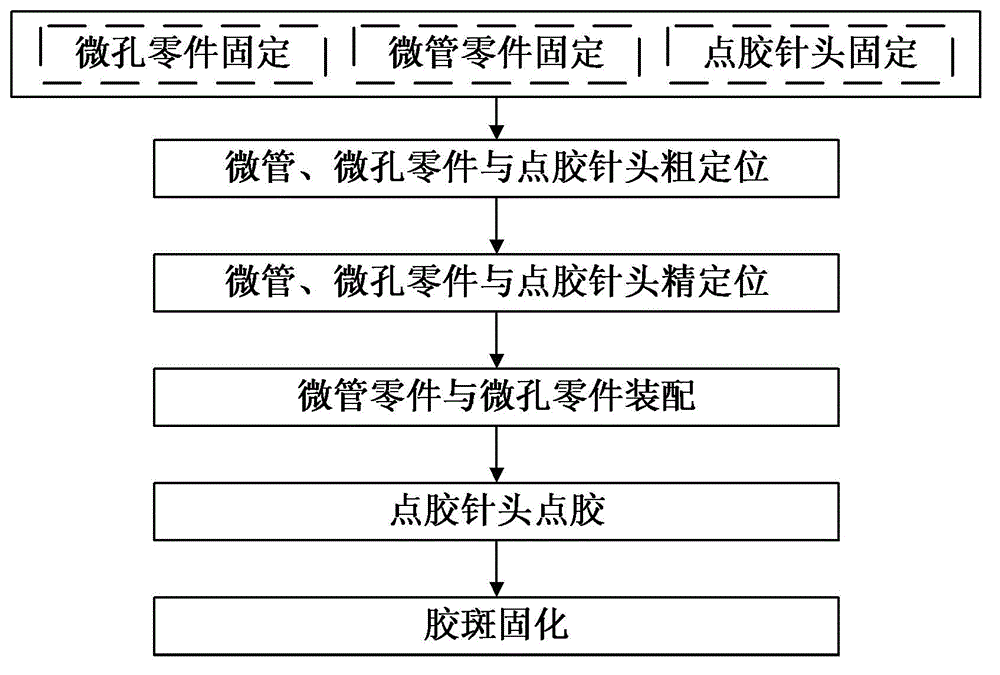

[0027] According to one embodiment of the present invention, the microscopic detection system includes multiple microscope components, and the magnification and field depth of each microscope component are different from each other, so that the depth of field of the images obtained by them are complementary to each other. In a preferred embodiment of the present invention, one microscope assembly among the plurality of microscope assemblies is a stereo microscope assembly, which is used for direct observation of the working area with the naked eye and includes eyepieces suitable for direct observation with the naked eye. In another preferred embodiment of the present invention, the microscopic detection system includes a first magnification microscope assembly and a second magnification microscope assembly, wherein the second magnification is greater than the first magnification, and the microscope assemblies of different magnifications are In order to be able to observe the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com