Embossing roller, embossing process and embossing paper using the embossing roller

An embossing roller and embossing technology, applied to the embossing roller, can solve the problems of reduced product strength, easy breakage in wet water, and product surface crushing, etc., and achieve the effects of high strength retention rate, improved aesthetics, and improved bulk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

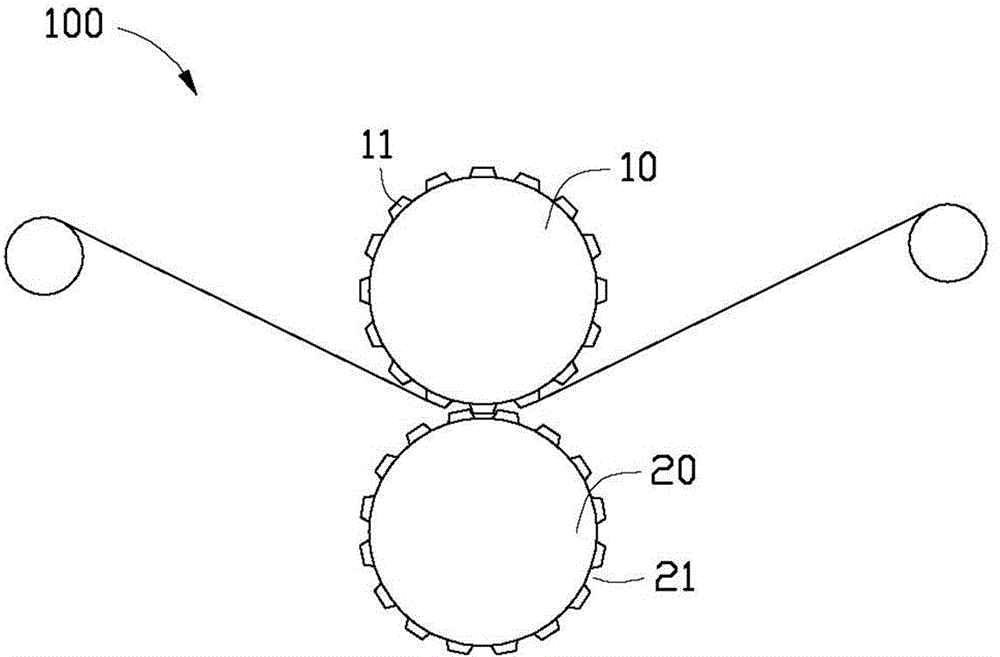

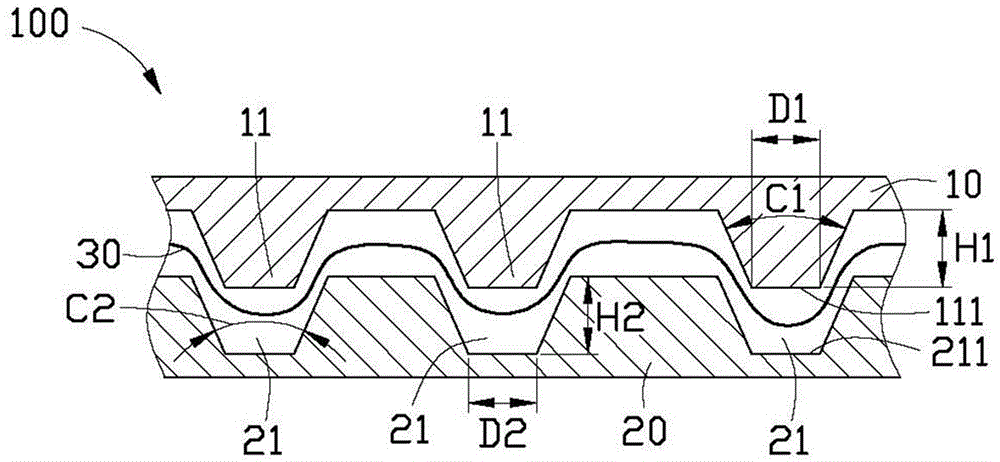

[0018] Please also refer to figure 1 with figure 2 , The embossing roll 100 of the present invention includes an upper embossing roll 10 and a lower embossing roll 20 that are matched. Both the upper embossing roll 10 and the lower embossing roll 20 are cylindrical and made of steel. The upper embossing roll 10 has a plurality of protrusions 11 extending outward, and the lower embossing roll 20 has a plurality of grooves 21 extending inward, and the protrusions 11 of the upper embossing roll 10 and the recesses of the lower embossing roll 20 The grooves 21 are arranged one-to-one. When the upper embossing roll 10 and the lower embossing roll 20 rotate with each other, the protrusions 11 of the upper embossing roll 10 extend into the corresponding grooves 21 of the lower embossing roll 20 .

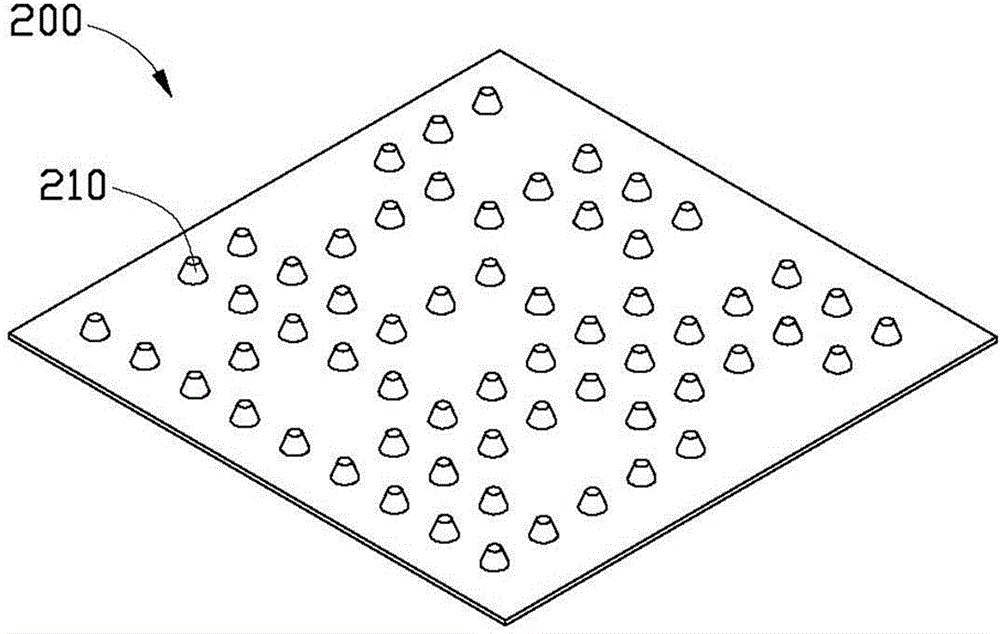

[0019] The plurality of protrusions 11 of the upper embossing roller 10 form a required pattern effect according to a certain arrangement. Each protrusion 11 is in the shape of a trunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com