Device for winding web of material

A bearing device and web rolling technology, which is applied in the field of devices for winding material webs into rolls, can solve problems such as inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

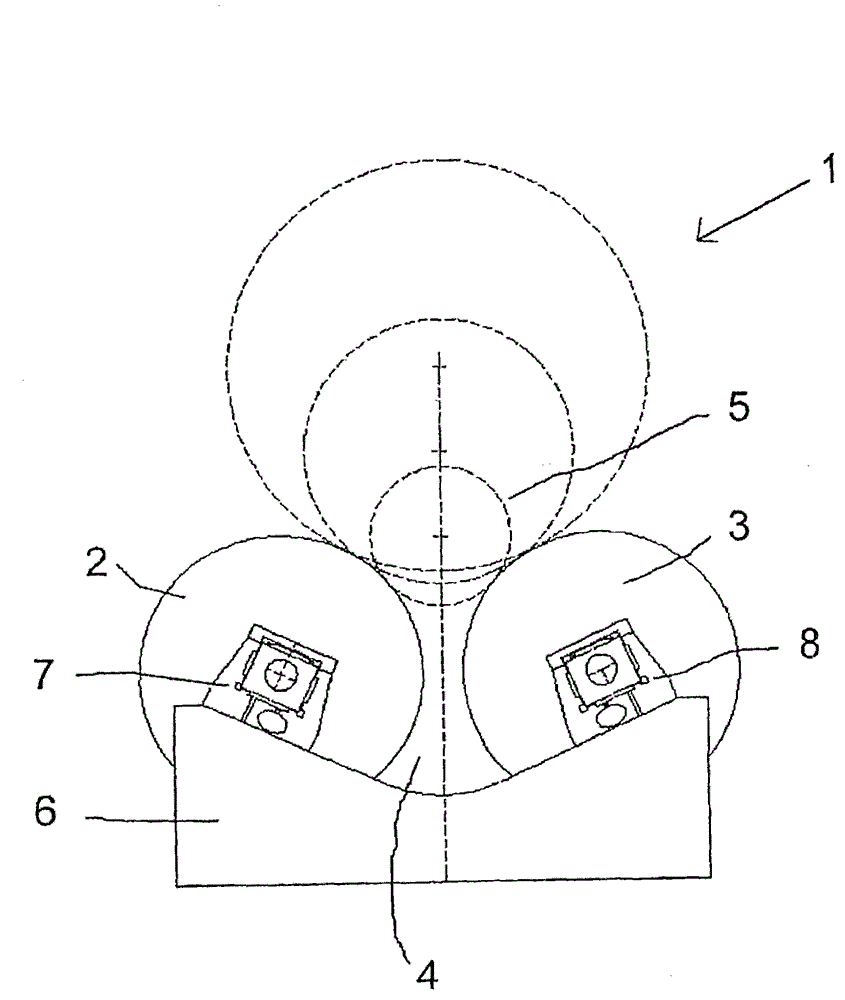

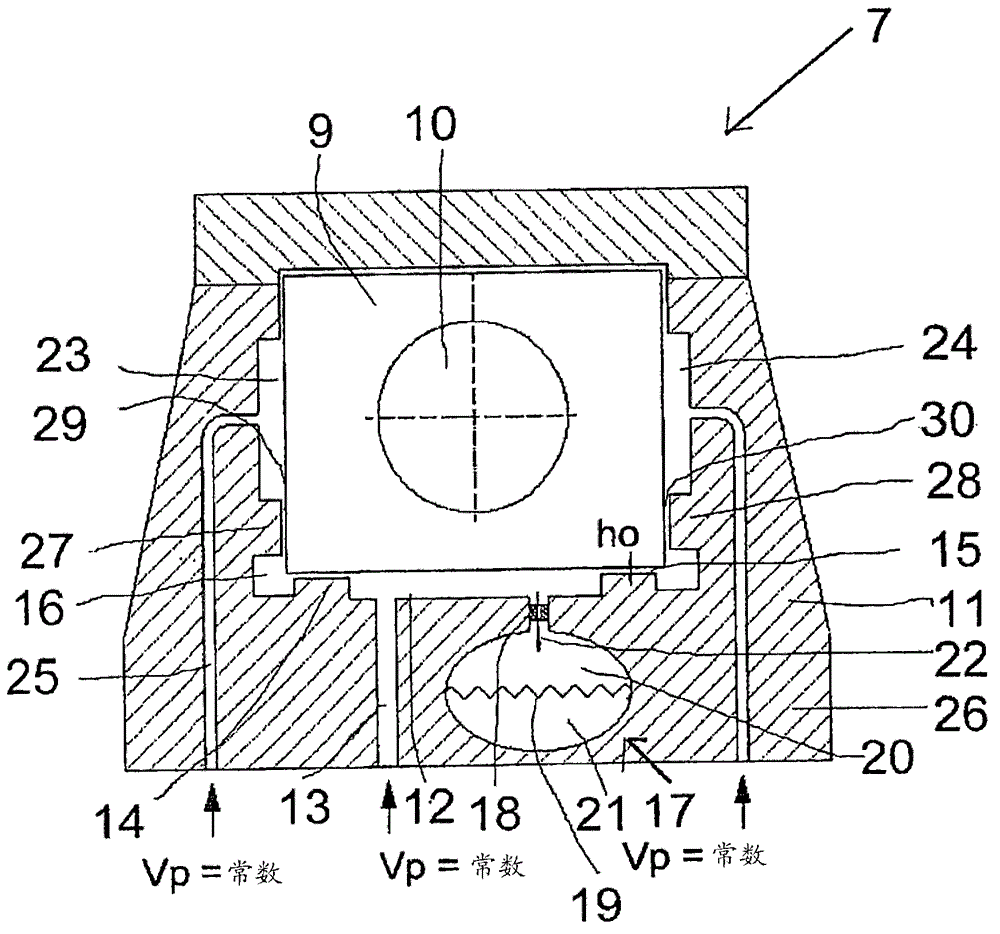

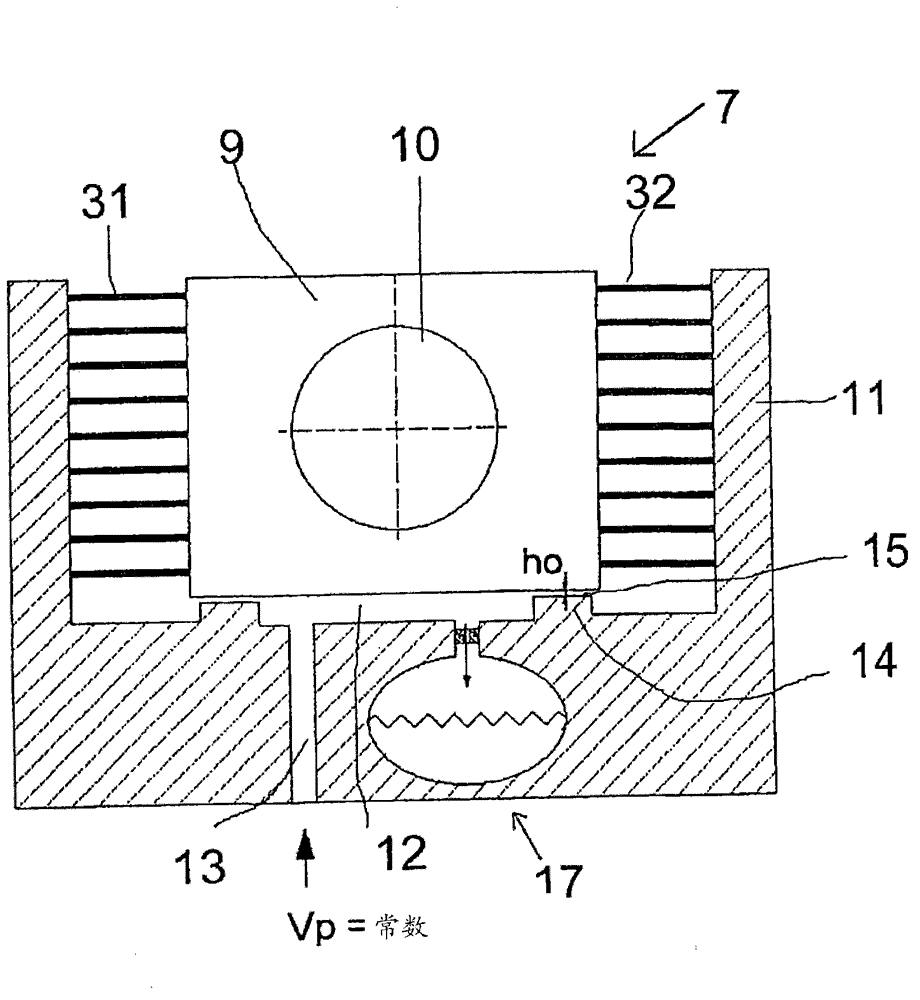

[0034] figure 1A winding device 1 is shown very schematically in the form of a double support roll winder. The winding device 1 has two support rollers 2, 3, between which a winding bed 4 is formed, in which a schematically shown mandrel 5 is arranged, onto which a not described in greater detail is wound. Material web. The structural arrangement of such a double backup roll winder is already known.

[0035] The two support rollers 2 , 3 are supported in a frame 6 . Each of the back-up rolls 2,3 has a bearing arrangement supported by a bearing 7,8 at each end of the back-up roll 2,3. Only bearings 7 and 8 are in figure 1 are visible separately.

[0036] This winding device can be operated at maximum conveying speed. The conveying speed is, for example, 2500 m / min or 3000 m / min. This results in a defined number of revolutions and thus a defined rotational frequency of the support rollers 2 , 3 . The winding device is designed for this rotational frequency. The number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com