Microfluidic chip based method for synthesizing needle-like hydroxyapatite nanoparticle

A microfluidic chip, hydroxyapatite technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

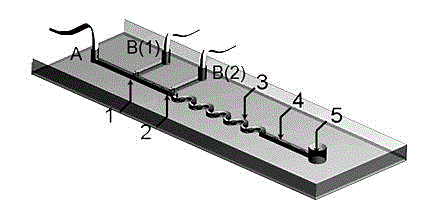

[0033] Droplet fusion and rapid mixing under different disperse phase flow rates using figure 1 The structure of the chip shown, see the actual figure 2 . The syringe pump continuously perfuses the reservoir A with mineral oil at a flow rate of 800 nl / min, and continuously perfuses the reservoir B (1) with deionized water at a flow rate of 500 nl / min. The flow rate ranges from 150 nl / min to 1000 nl / min. The inner pair of reservoir B (2) was continuously perfused with a 20 mg / ml amaranth dye solution. Water-in-oil droplets (deionized water / mineral oil) are continuously formed at the first-stage T-shaped channel 1, and driven by mineral oil to flow along the channel through the second-stage T-shaped channel 2 to meet the amaranth solution , through the three processes of collision, oil discharge, and oil film rupture, the amaranth solution enters the droplet and realizes fusion, such as Figure 4 shown. Keeping the flow rate of the continuous phase of mineral oil and the d...

Embodiment 2

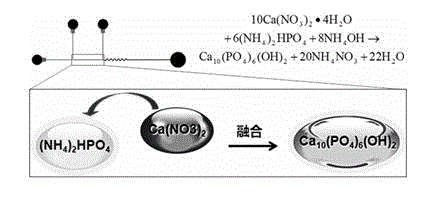

[0035] Synthesis and electron microscope characterization of acicular hydroxyapatite nanoparticles. Diamine hydrogen phosphate was dissolved in deionized water to prepare a 0.06 mol / L solution. The solution contained 0.1 mol / l ammonia water to control the droplets after fusion. The pH value of the phase solution (10~11); calcium nitrate was dissolved in deionized water to prepare a 0.1mol / L solution. Use a syringe pump to continuously perfuse mineral oil to reservoir A at a flow rate of 800 nl / min, and to continuously perfuse 0.06 mol / L aqueous ammonia solution of diamine hydrogen phosphate to reservoir B (1), and to perfuse the reservoir at a flow rate of 500 nl / min. Pool B (2) was continuously perfused with 0.1 mol / L calcium nitrate solution. Droplets of phosphorus-in-oil precursor (phosphorus precursor / mineral oil) are continuously formed at the first-stage T-shaped channel 1, and driven by mineral oil to flow along the channel through the second-stage T-shaped channel 2 an...

Embodiment 3

[0037] Droplet fusion and rapid mixing of different dyes as dispersed phases, using figure 1 The chip with the structure shown is shown in figure 2 . The syringe pump continuously perfused mineral oil into reservoir A at a flow rate of 800 nl / min, continuously perfused 20 mg / ml amaranth dye solution into reservoir B (1) at a flow rate of 500 nl / min, and Reservoir B (2) was continuously perfused with 20 mg / ml bromocresol blue dye solution. Droplets of the oil-in-amaranth solution (maranth / mineral oil) are continuously formed at the first-stage T-shaped channel 1, and the droplets flow along the channel through the second-stage T-shaped channel 2 under the driving of the mineral oil. When bromocresol blue solutions meet, through three processes of collision, oil discharge and oil film rupture, the bromocresol blue solution enters the droplets to achieve fusion. It can be seen from the observation that when the droplet moves in the curved channel, the bromocresol blue dye mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com