Preparation method for anti-oxidant silica-based ceramic coating with wide temperature range for carbon/carbon composite

A carbon composite material and anti-oxidation silicon-based technology, which is applied in the field of preparation of carbon/carbon composite material anti-oxidation silicon-based ceramic coatings in a wide temperature range, can solve the problems of insufficient bonding force, unsatisfactory coating compactness, and limitations. Problems such as thermal expansion mismatch, to overcome the effect of poor compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

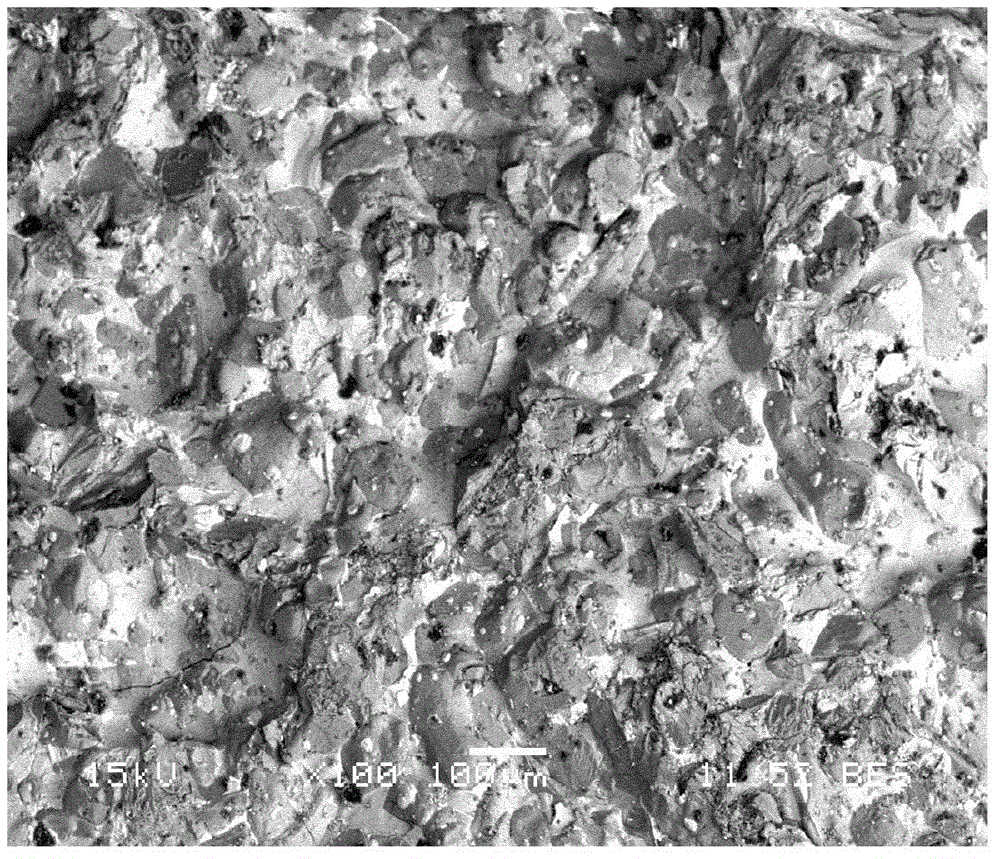

[0028] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0029] Weigh 75g of Si powder, 15g of SiC powder, 15g of C powder, 10g of Al 2 o 3 pink. Place in a turpentine ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours to obtain embedding powder.

[0030] Put 1 / 4 of the embedding powder into the graphite crucible, put the prepared C / C composite material, then put 1 / 4 of the embedding powder, shake the crucible slightly, so that the powder can evenly embed C / C composite material, and then put the graphite crucible into a vertical vacuum furnace with graphite as a heating element. After evacuating for 30 minutes, make the vacuum degree reach -0.09MPa, keep the vacuum for 30 minutes, and observe whether the indicati...

Embodiment 2

[0034]The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0035] Weigh 78g of Si powder, 10g of SiC powder, 11g of C powder, 6g of A l 2O 3 pink. Place in a turpentine ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 3 hours to obtain embedding powder.

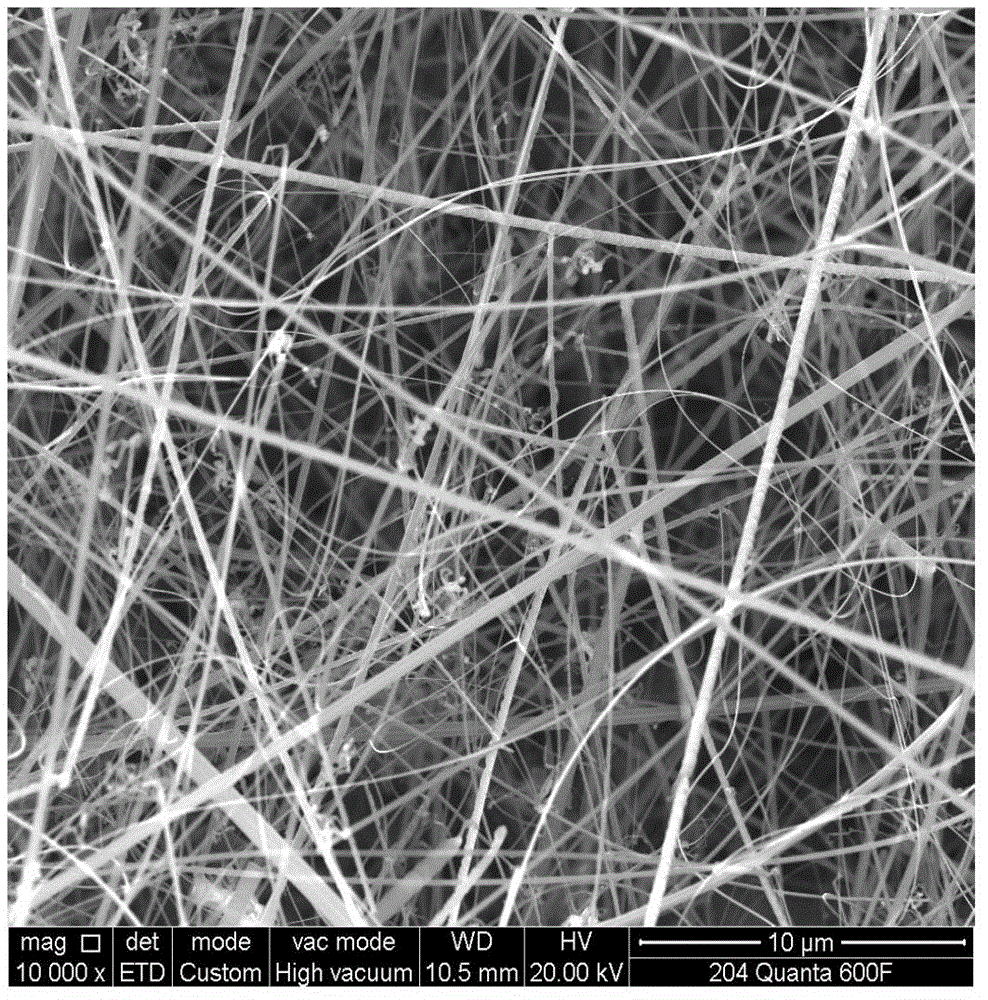

[0036] Put 1 / 4 of the embedding powder into the graphite crucible, put the prepared C / C composite material, then put 1 / 4 of the embedding powder, shake the crucible slightly, so that the powder can evenly embed C / C composite material, and then put the graphite crucible into a vertical vacuum furnace with graphite as a heating element. After evacuating for 30 minutes, make the vacuum degree reach -0.09MPa, keep the vacuum for 30 minutes, and observe whether the indication...

Embodiment 3

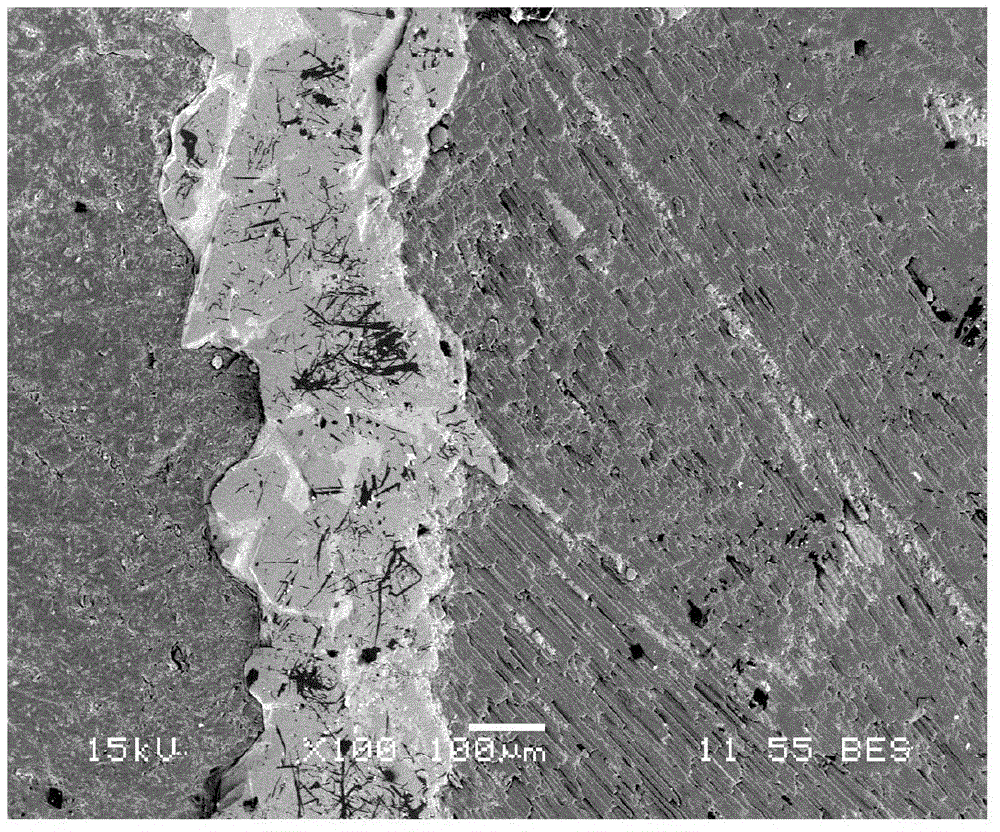

[0040] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0041] Weigh 85g of Si powder, 5g of SiC powder, 7g of C powder, 3g of Al 2 o 3 pink. Place in a turpentine ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 4 hours to obtain embedding powder.

[0042] Put 1 / 4 of the embedding powder into the graphite crucible, put the prepared C / C composite material, then put 1 / 4 of the embedding powder, shake the crucible slightly, so that the powder can evenly embed C / C composite material, and then put the graphite crucible into a vertical vacuum furnace with graphite as a heating element. After evacuating for 30 minutes, make the vacuum degree reach -0.09MPa, keep the vacuum for 30 minutes, and observe whether the indication ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com