High-frequency low-iron-loss excellent-magnetic-property non-orientated silicon steel strip and production method thereof

A technology of oriented silicon steel and its production method, which is applied in the field of production of non-oriented silicon steel strips, can solve the problems that cannot meet the needs of high-performance motors and other precision magnetic materials manufacturing and research and development, and need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

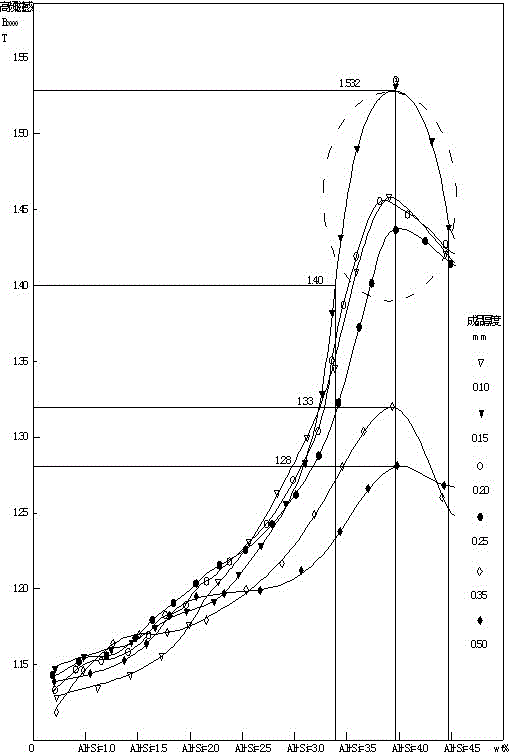

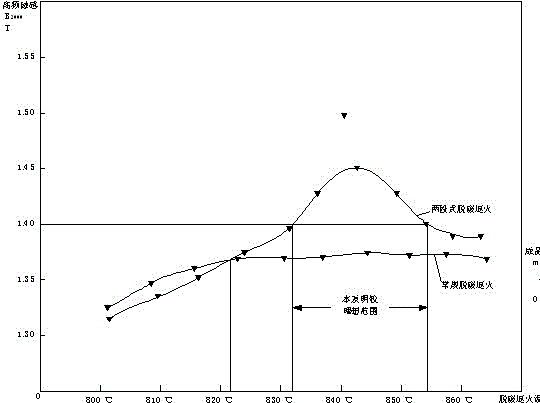

[0043] Example 2: With C0.002wt%, Si2.92wt%, Mn0.25wt%, S0.0018wt%, P0.017wt%, N0.002wt%, Als0.685wt%, Cr2.4wt%, Cu0.06wt% , Sn0.030 wt%, and Ti0.001 wt% are the basic components, and the rest is Fe and unavoidable components. After the slab is soaked at a.1120°C and b.1130°C for 80 minutes, it starts Direct hot rolling, after 5 passes rough rolling 45mm, 6 passes rolling into 2.2mm thick hot rolled plate. After that, after the hot rolling is finished, it is air-cooled for 3 seconds, and then cooled with water to 600-650°C for coiling. Infrequent treatment of hot-rolled plates The hot-rolled sheet is normalized at 750°C for 3 minutes The hot-rolled sheet is normalized at 820°C for 3 minutes The hot-rolled sheet is normalized at 950°C for 3 minutes, then pickled and cold-rolled to 0.45 mm for the first time with a reduction rate of about 80%, and then undergoes two-stage decarburization annealing at 820-950°C×300s to eliminate work hardening. The reduction rate is about...

example 3

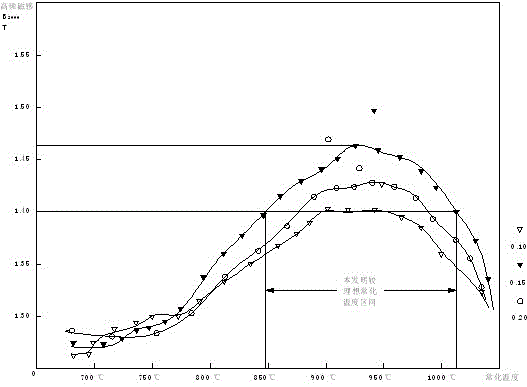

[0045] Example 3: With C0.005wt%, Si3.12wt%, Mn0.26wt%, S0.0025wt%, P0.014wt%, N0.0018wt%, Als0.654wt%, Cr2.2wt%, Cu0.05wt% , Sn0.020 wt%, and Ti0.001 wt% are the basic components, and the rest is Fe and unavoidable components. After the slab is soaked at a.1120°C and b.1130°C for 80 minutes, it starts Direct hot rolling, after 5 passes rough rolling 45mm, 6 passes rolling into 2.2mm thick hot rolled plate. After that, after the hot rolling is finished, it is air-cooled for 3 seconds, and then cooled with water to 600-650°C for coiling. The hot-rolled sheet was normalized at 950°C for 3 minutes, then pickled and cold-rolled to 0.45 mm for the first time with a reduction rate of about 80%. 820~860℃×300sN 2 、H 2 Conventional decarburization annealing under wet atmosphere, 820~860℃×300sN 2 、H 2 Two-stage decarburization annealing under atmosphere, the first stage is 180sN 2 、H 2 Concentrated decarburization in wet atmosphere, and non-decarburization in the later stage o...

example 4

[0048] Example 4: With C0.003wt%, Si3.25wt%, Mn0.24wt%, S0.002wt%, P0.019wt%, N0.002wt%, Als0.586wt%, Cr2.3wt%, Cu0.08wt% , Ti0.001 wt% as the basic composition, adding Sn0.001 wt% Sn0.005 wt% Sn0.04wt% 230mm slab made of Sn0.08wt%, the rest is Fe and unavoidable composition, after the slab is soaked at a.1120℃, b.1130℃ for 80 minutes, it starts to be directly hot-rolled, and after 5 passes of rough rolling 45mm , 6 passes rolled into 2.2mm thick hot-rolled sheet. After that, after the hot rolling is finished, it is air-cooled for 3 seconds, and then cooled with water to 600-650°C for coiling. The hot-rolled sheet is normalized at 950°C for 3 minutes, then pickled and cold-rolled to 0.45 mm for the first time with a reduction rate of about 80%, and then undergoes two-stage decarburization annealing at 820-850°C×300s to eliminate work hardening. The reduction rate is about 67%. The second cold rolling includes a critical rolling and finally reaches 0.15mm, and then pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com