Construction tool for glues

A construction tool and glue technology, applied in the field of auxiliary tools for decoration construction, can solve the problems of poor bonding effect, waste of colloid, uneven surface of the colloid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

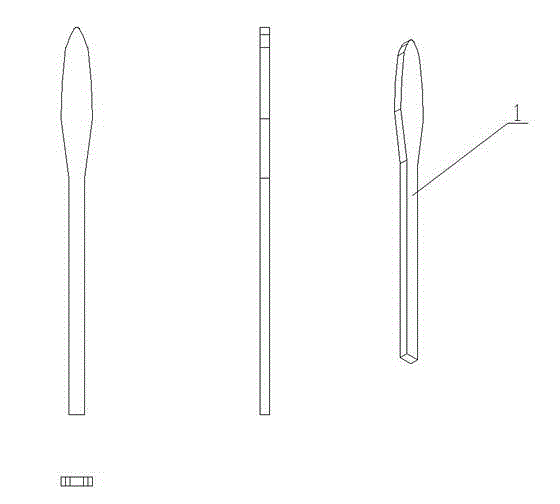

[0022] The area of the front side 3 is smaller than the area of the back side 4, and the angle between the connecting surface 5 and the back side 4 is 45 degrees, that is, the cross-section of the tool head 2 is an isosceles trapezoid with a base angle of 45 degrees, and the front side 3 and the back side 4 The contours of both have the same shape, and they are all parabolic-like shapes formed by multiple smooth transition curves (such as figure 1 , figure 2 , image 3 shown), that is, its profile is an axisymmetric smooth curve. When in use, use the curved connecting surface 5 or the back surface 4 to smooth and squeeze the glue.

Embodiment 2

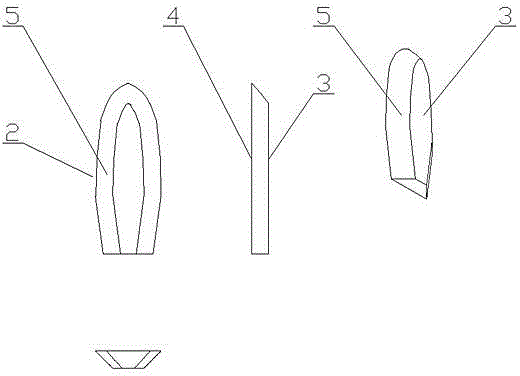

[0024] The area of the front side 3 is smaller than the area of the back side 4, and the angle between the connecting surface 5 and the back side 4 is 45 degrees, that is, the cross-section of the tool head 2 is an isosceles trapezoid with a base angle of 45 degrees, and the front side 3 and the back side 4 The contour shapes of the two trapezoids are the same, they are all isosceles trapezoids, and the end of this isosceles trapezoid near the handle 1 is its short side, and the bottom corners of the two trapezoids on the long side are smooth rounded transitions (such as Figure 4 , Figure 5 , Figure 6 shown), when in use, use the connection surface 5 or the back surface 4 to smooth and squeeze the glue.

Embodiment 3

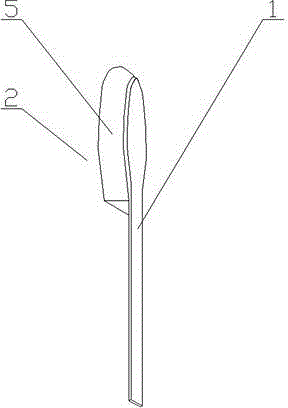

[0026] The area of the front 3 is smaller than the area of the back 4, and the contours of the front 3 and the back 4 are convex (such as Figure 7 , Figure 8 , Figure 9 shown), and the angle between the connection surface 5 and the back surface 4 at the front end (that is, the protruding end) of the convex shape is 45 degrees, and the angles between the connection surface 5 and the back surface 4 and the front surface 3 of other parts are equal It is 90 degrees. When in use, the front end of the convex shape (that is, the protruding end set at an angle) is used to smooth and squeeze the glue, which is suitable for the construction of glue in a gap with a certain width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com