Reverse-procedure installation technology for fully mechanized mining face

A technology of fully mechanized mining face and installation process, which is applied in ground mining, earthwork drilling, underground mining, etc., and can solve the problems of safe installation of fully mechanized mining equipment and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

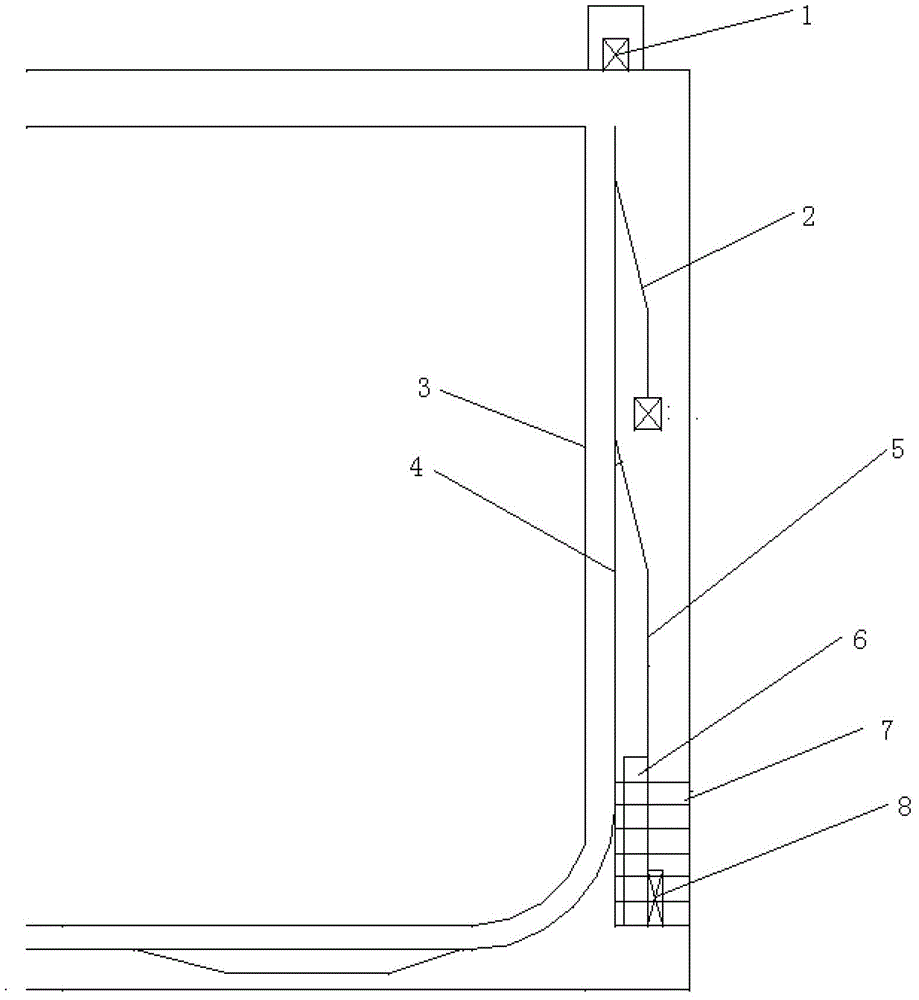

[0013] Such as figure 1 Shown, installation method of the present invention is as follows:

[0014] The first step: widen the width of the cut hole, which is one set of track width more than the width of the ordinary cut hole, generally 1.2 meters more. To strengthen the roof support, according to the conditions of the roof, use anchor belt nets with anchor cables or anchor belt nets with single pillars to support the widened roof.

[0015] Step 2: Lay double rails in the opening, lay the main rail 4 on the side close to the coal wall 3, and lay the auxiliary rail 5 at the installation position of the bracket; the main rail 4 and the auxiliary rail 5 are connected by the switch 2, and the installation distance between the switch 2 is not large. If it is greater than 100 meters, avoid repeated lifting distances that are too long, resulting in a slowdown in installation speed.

[0016] The third step: transport the coal shearer 8 from the lower slot to the lower part of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com