Driving-driven hybrid vibration isolator

A hybrid vibration isolator, active and passive technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of easily damaged actuators, large amount of permanent magnets, and poor closure of magnetic circuits , to achieve the effect of convenient use, simple wiring, and effective attenuation of vibration energy transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

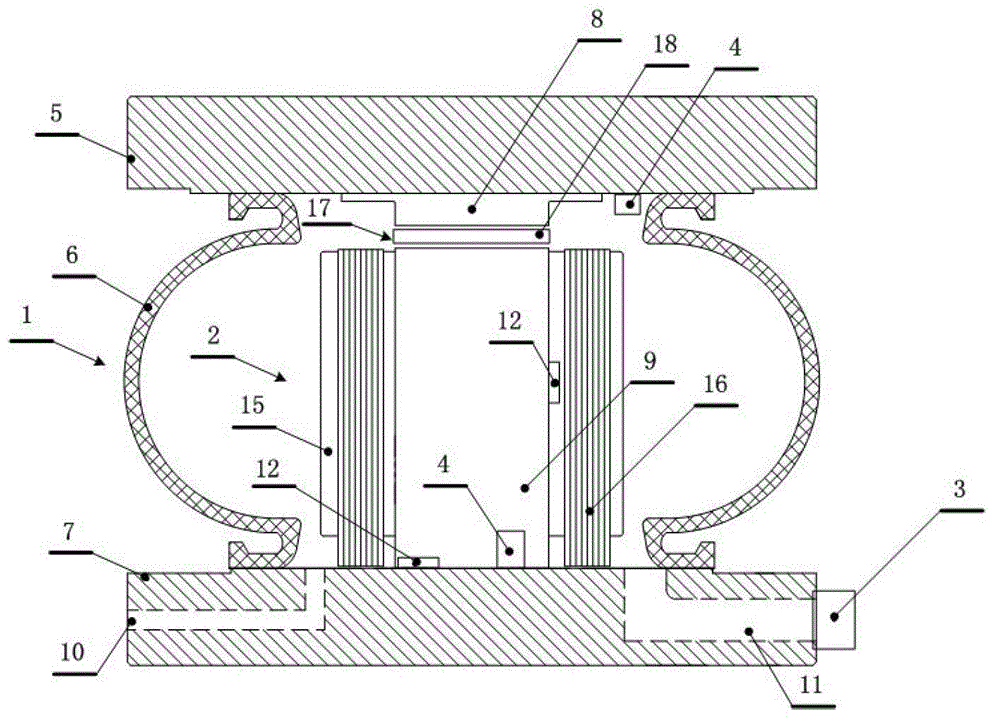

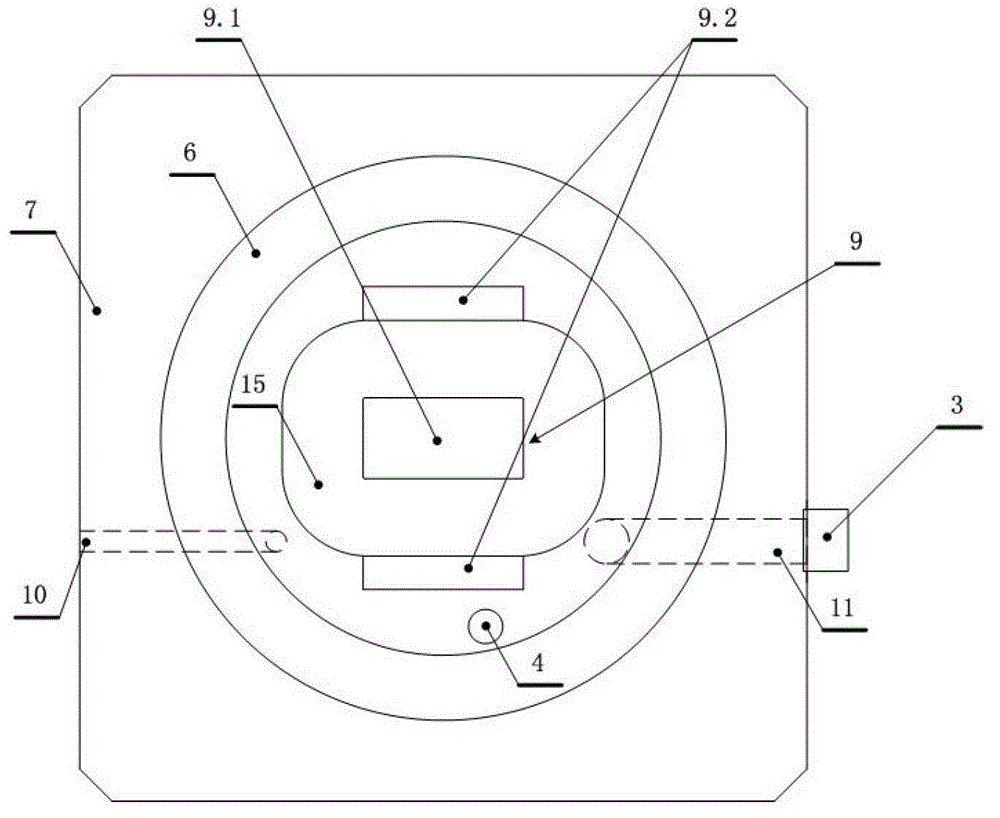

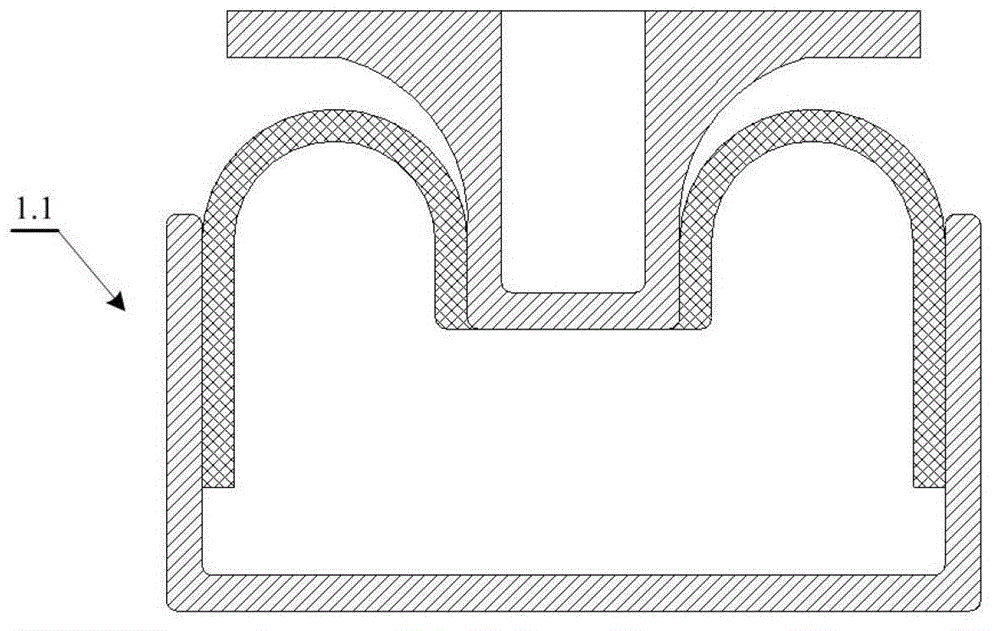

[0031] The active and passive hybrid vibration isolators shown in Figures 1 to 4 include an airbag vibration isolator 1, and the airbag vibration isolator 1 includes an upper cover plate 5, a lower cover plate 7, and is arranged between the upper cover plate 5 and the lower cover plate 7. Between the elastic capsule 6, the elastic capsule 6 is provided with an electromagnetic actuator 2, the electromagnetic actuator 2 includes an armature 8, an iron core 9 matched with the armature 8, and a coil 15 wound on the iron core 9, wherein, The armature 8 is fixed on the bottom of the upper cover plate 5, and the iron core 9 is fixed on the top of the lower cover plate 7. There is an air gap 17 between the armature 8 and the iron core 9. The coil 15 is provided with a cooling fin 16, and the bottom of the cooling fin 16 is connected to The lower cover 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com