Floodlight total-reflection lens and LED (Light Emitting Diode) lamp using lens

A technology of LED lamps and total reflection, applied in the field of LED lamps and floodlight total reflection lenses, can solve the problems of large lens size, small floodlight angle, low utilization rate of light efficiency of lamps, etc., achieve small size and improve illumination uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

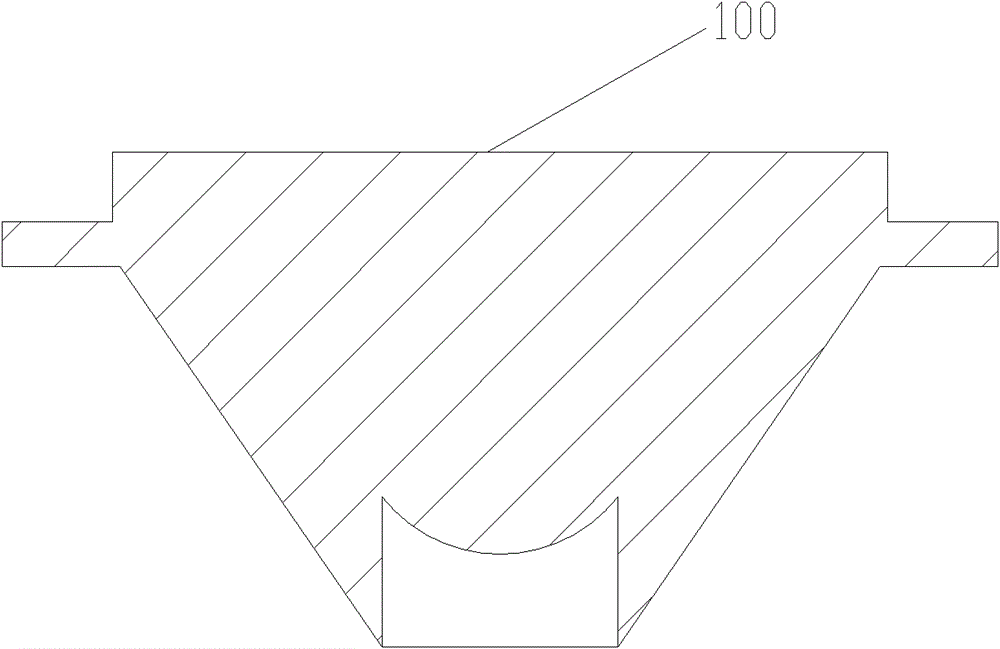

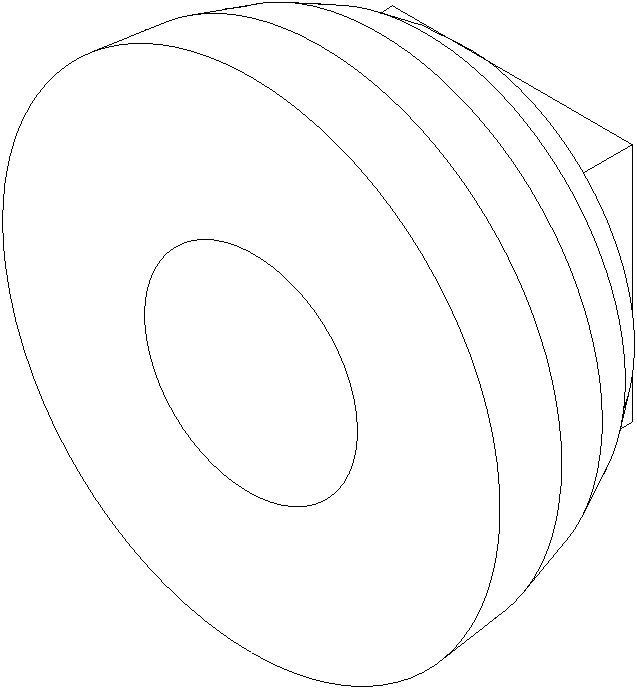

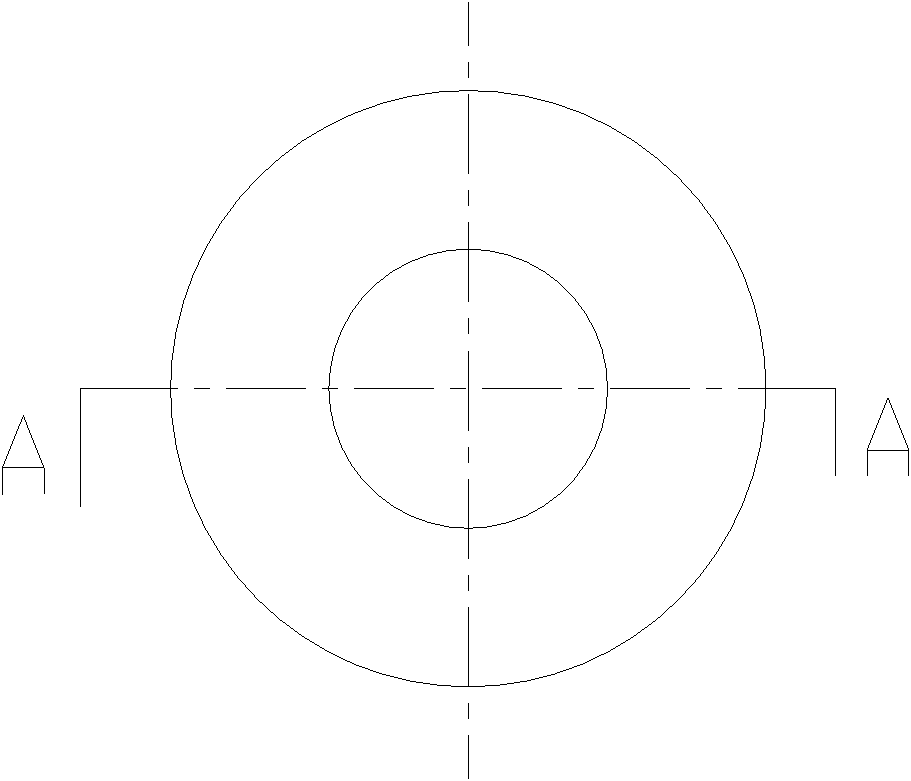

[0034] Such as figure 2 shown, see also image 3 with Figure 4 . In a preferred embodiment of the present invention, the total reflection lens is a revolving body whose revolving generatrix is a broken line, wherein the revolving body's revolving generatrix is formed by successively connecting four line segments, the bottom of which is provided with a light source installation hole, and the center of its light-emitting surface is provided with There is a conical concave surface 3 whose apex falls on the symmetry axis of the total reflection lens. The above-mentioned light source installation hole includes a cylindrical blind hole 1 located at the center of the incident surface of the total reflection lens, and a conical concave hole 2 connected to the cylindrical blind hole 1, wherein the cylindrical blind hole 1 is used for installi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com