On-site testing method for dry density of fine sand subgrade

A field test, dry density technology, used in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of increased void ratio, feasibility limitation, low dry density of test results, etc., to reduce test errors and reduce the degree of disturbance. , the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

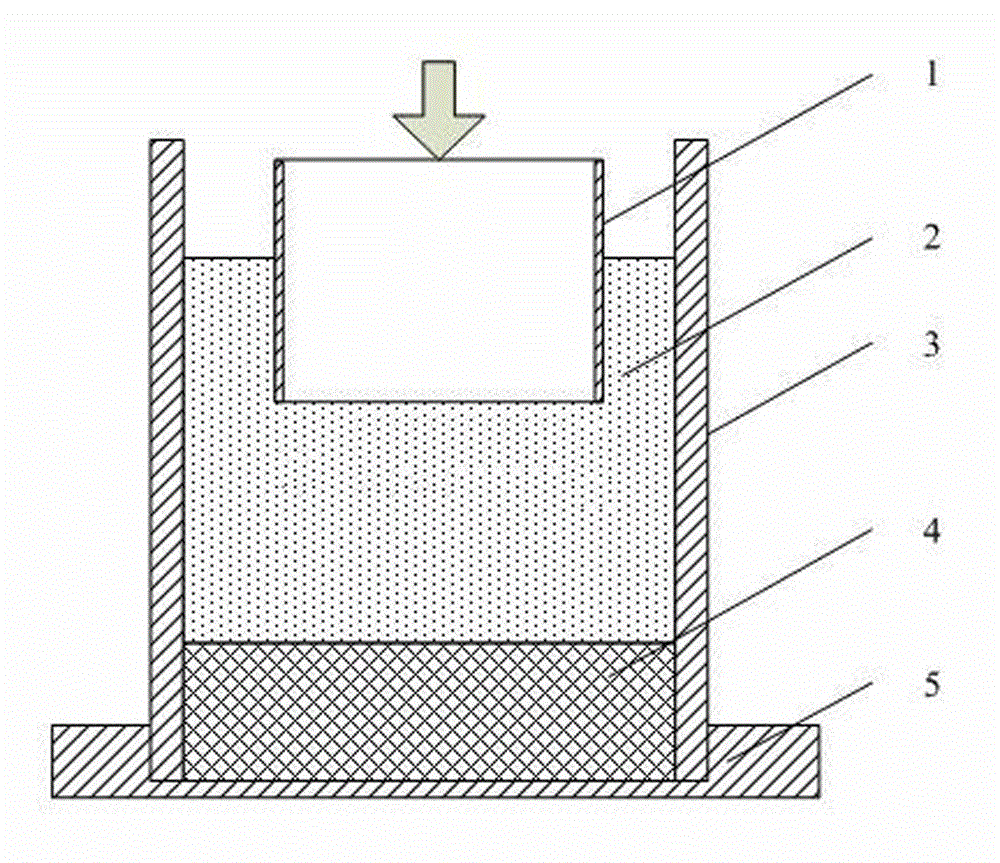

[0022] Example: such as figure 1 As shown, the test process of this embodiment is carried out on the heavy-duty compaction instrument 3. The heavy-duty compaction instrument 3 is a sleeve structure containing a cavity, and its bottom is a double-layer sealing structure, which is composed of a backing plate 4 and a bottom plate 5. , which accommodates the interior of the cavity for placing the sample fine sand 2 .

[0023] This embodiment is realized through the following steps:

[0024] 1. Take a representative sample of 20-30g (fine sand 2 with a limited weight) as a sample, put it into the cavity of the heavy-duty compactor 3 (inner diameter 15.2cm, height 7cm), cover the lid immediately and weigh When weighing the mass, you can put a weighing box of equal mass or a weight of the box and other mass on one end of the balance, and the weighing result is the mass of fine sand 2 under the condition of water content in that year.

[0025] 2. Use a dropper to inject alcohol in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com