Method for establishing virtual prototype of hydraulic excavator

A technology for hydraulic excavators and virtual prototypes, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high design costs and long design cycles, and achieve reduced test costs, accurate results, and improved modeling process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

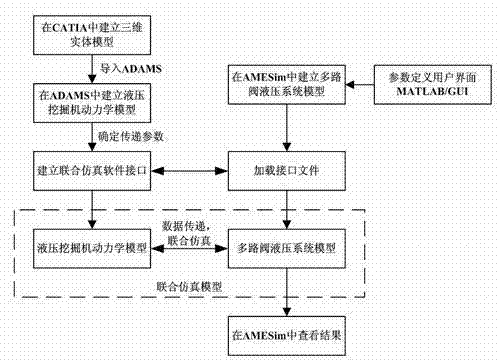

[0021] The establishment method of the hydraulic excavator virtual prototype of the present invention, such as figure 1 shown, including the following steps:

[0022] Step 1: Establish the dynamic model of the hydraulic excavator in the dynamic simulation software ADAMS, and establish the multi-valve hydraulic system model of the hydraulic excavator in the hydraulic system simulation software AMESim;

[0023] Step 2: Use the dynamic model and the related state variables and parameters associated in the simulation process of the multi-way valve hydraulic system model as the transfer parameters between the two models, and use the Controls module of the ADAMS software and the interface module of the AMESim software to establish Software interface, real-time data transmission, joint simulation of excavator dynamic model and multi-valve hydraulic system model;

[0024] Step 3: Check the simulation results in the hydraulic system simulation software.

[0025] In a preferred embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com