Overvoltage protection circuit, power module and overvoltage protection method

A technology for protecting circuits and power modules, which is used in protection against overvoltage, emergency protection circuit devices, electrical components, etc. It can solve the problem of main power shutdown, protection circuit malfunction, and large difference in OVP overvoltage checkpoints of power supply boards. and other problems, to achieve the effect of accurate setting value, reducing difficulty, and overcoming the malfunction of the protection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

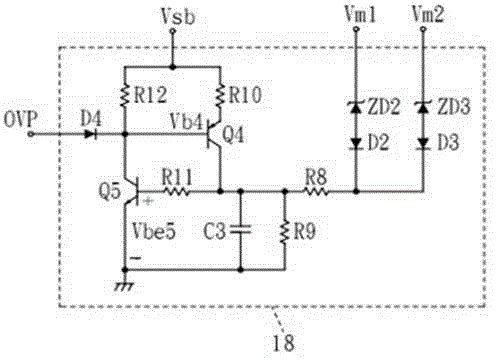

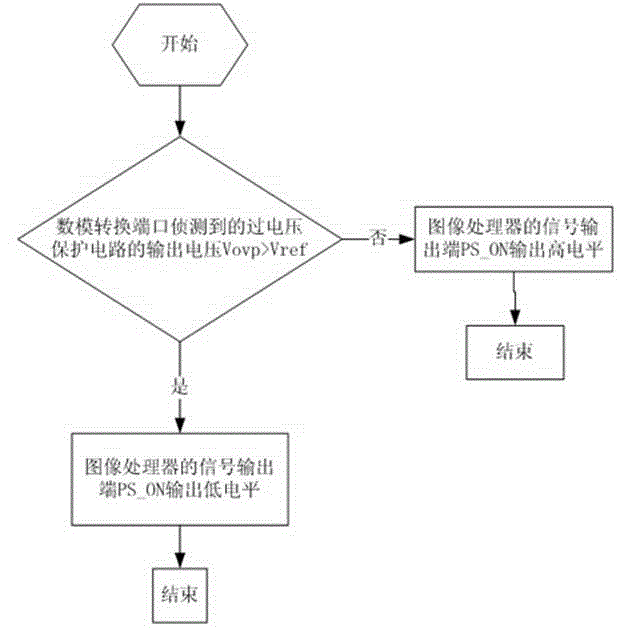

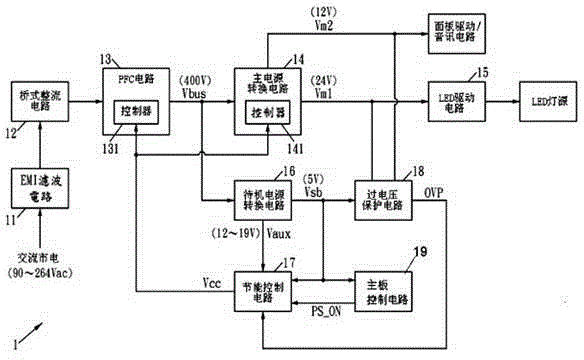

[0034] figure 1 It is a block diagram of a power supply module of an existing high-power liquid crystal display product. See figure 1 , the power module 1 includes an electromagnetic interference (Electro Magnetic Interference, EMI) filter circuit 11, a bridge rectifier circuit 12, a power factor correction (Power Factor Correction, PFC) circuit 13, a main power conversion circuit 14, a light-emitting diode (Light-Emitting Diode , LED) drive circuit 15 , standby power conversion circuit 16 , energy saving control circuit 17 and overvoltage protection circuit 18 . AC mains (such as 90-264Vac) passes through EMI filter circuit 11 to filter out conductive EMI noise, bridge rectifier circuit 12 for full-wave rectification, PFC circuit 13 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com