Device for obtaining a multicrystalline semiconductor material, in particular silicon, and method for controlling the temperature therein

A semiconductor and polysilicon technology, applied in the field of polysilicon semiconductor materials, can solve problems such as high energy consumption and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

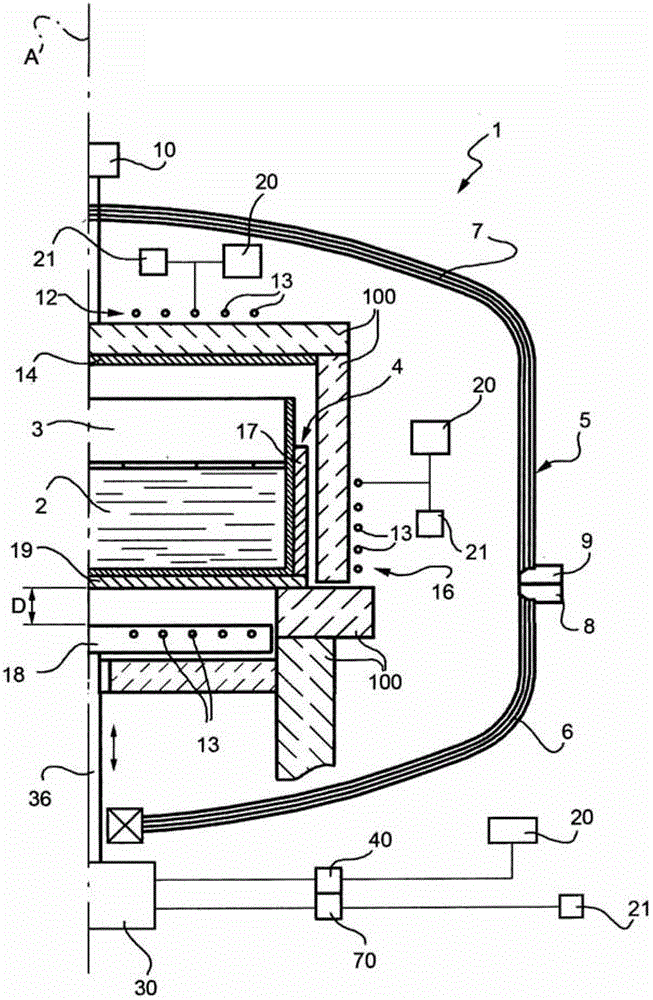

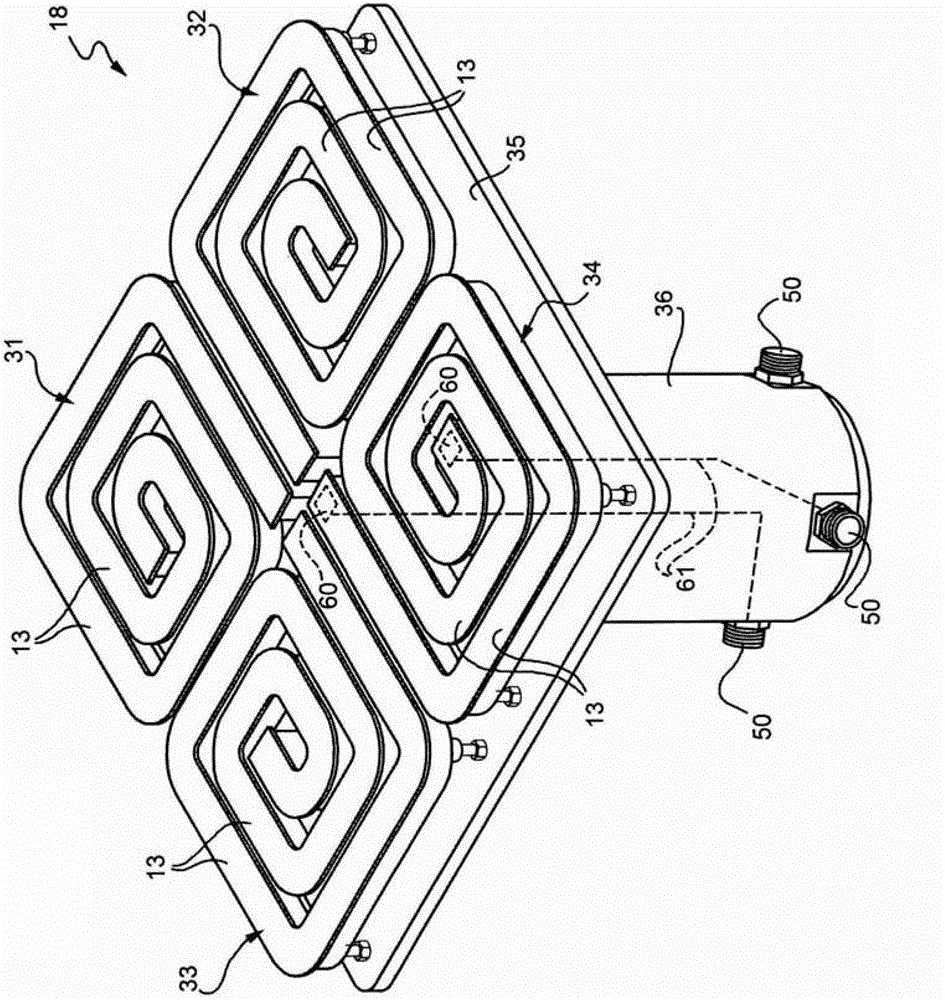

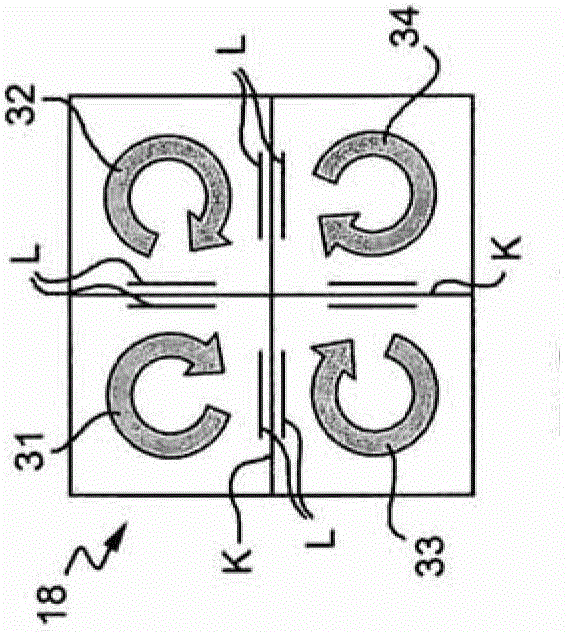

[0020] refer to figure 1 and 2 , an apparatus for melting and subsequent directional solidification of semiconductor material 2 , in particular for obtaining polysilicon of “solar purity”, is indicated overall by 1 .

[0021] Said device 1 comprises: at least one crucible 3 for semiconductor material 2, preferably made of quartz or ceramic material, removably housed in a cup-shaped graphite container 4; and a fluid-tight enclosure 5, inside which The graphite container 4, fluid-tight cover 5 comprises a cup-shaped bottom half-shell 6 and top half-shell 7; said bottom half-shell 6 and top half-shell 7 are preferably made of steel, usually with their concave faces facing each other connected one above the other ( figure 1 ), and appropriate gaskets (not shown) are provided on each edge 8, 9 to butt together in a fluid-tight manner.

[0022] Said apparatus 1 further comprises means 10 for vertically removing the top half-shell 7 from the bottom half-shell 6 so that the cover 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com