Curve cutting equipment

A cutting equipment and curve technology, applied in the field of curve cutting equipment, can solve the problems of poor product edge effect, inconvenient curve cutting, loud vibration machine noise, etc., and achieve the effects of low cost, low cutting energy consumption, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

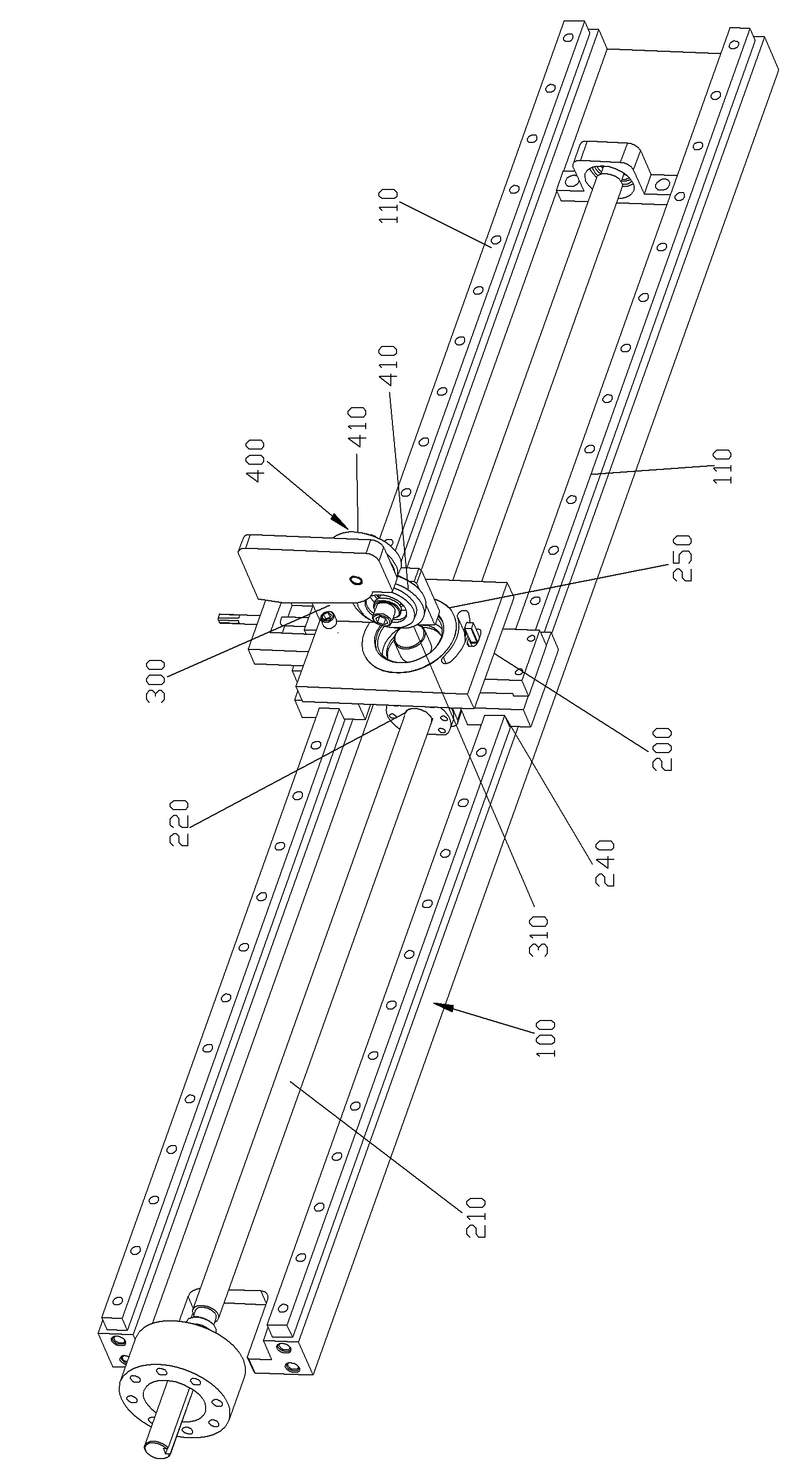

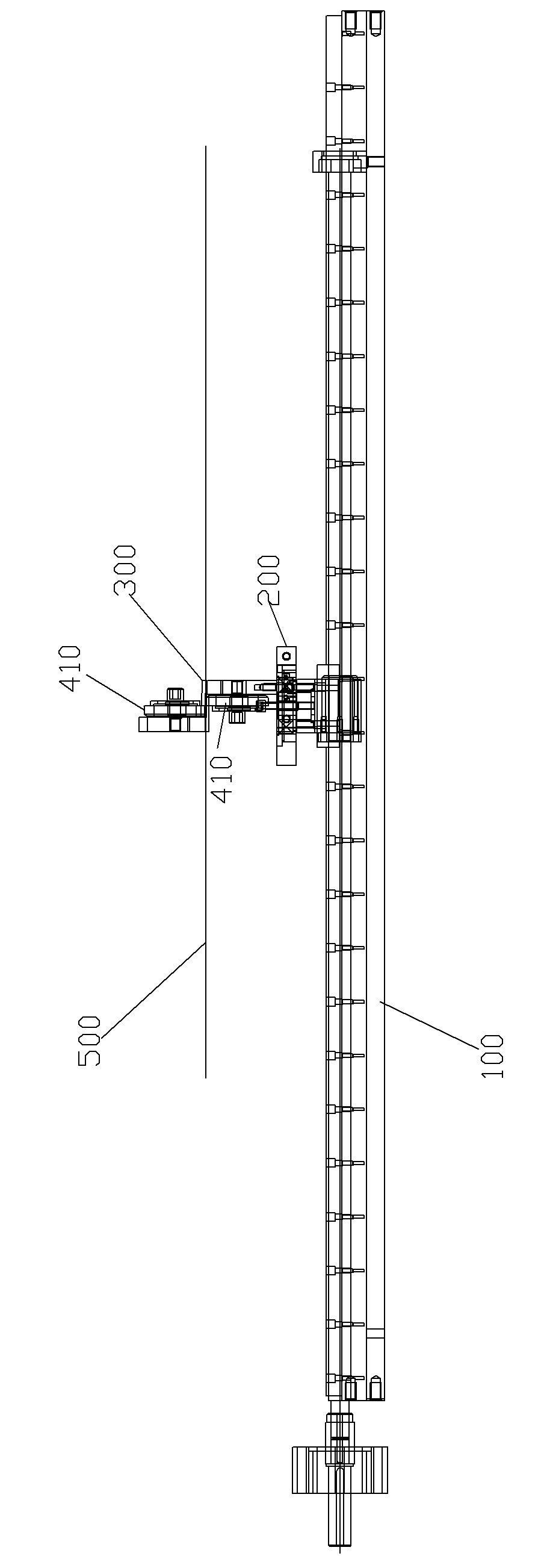

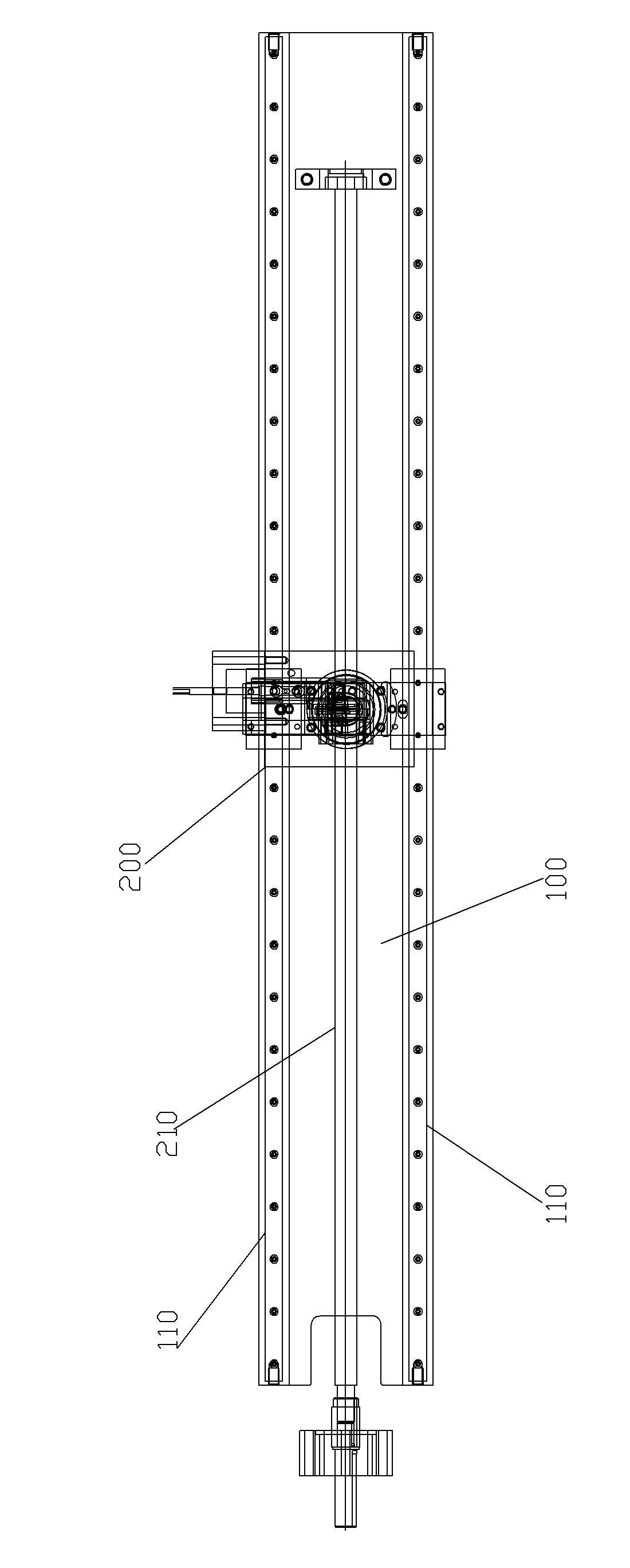

[0030] Please check Figure 1 to Figure 4 , curve cutting equipment, which includes a frame 100, a first unit, a second unit, a knife frame 300, a cutting knife group 400 and a control mechanism. The X-axis, Y-axis, and Z-axis described below can be defined like three-dimensional coordinates. In this embodiment, the cutting device is used for cutting strips for the thin steel plate (to-be-cut object 500 ).

[0031] The first unit is installed on the frame 100 and includes a first power part and a conveying mechanism, and the first power part is connected to the conveying mechanism by transmission so as to make the conveying mechanism move so as to drive the object to be cut to move along the X axis . In this embodiment, the conveying mechanism may be a conveying roller mechanism, a conveyor belt mechanism, a sliding seat mechanism, a hydraulic mechanism, a screw nut mechanism and the like.

[0032] The second unit is installed on the frame 100 and includes a second power pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com