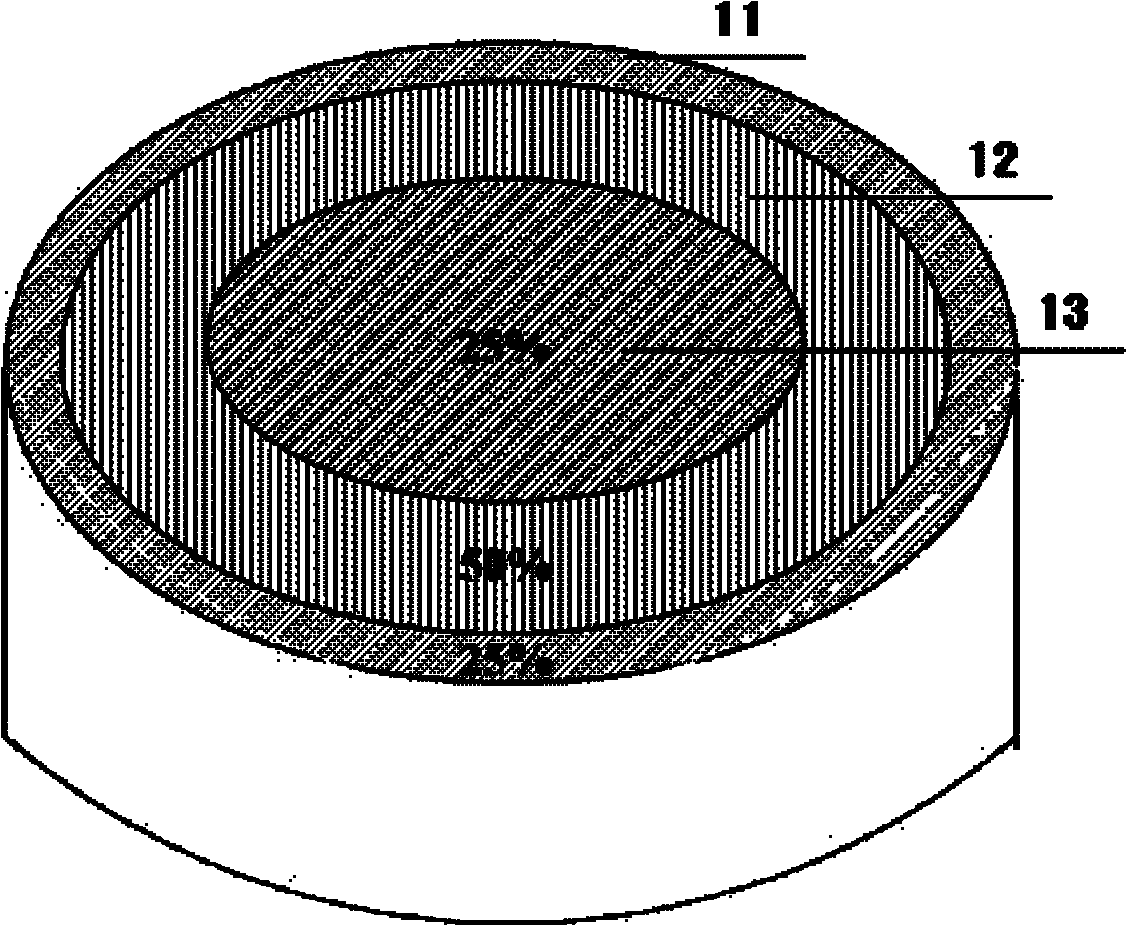

Method for evaluating material distribution uniformity of bell-less blast furnace

A technology of uniformity and distribution, which is applied in the field of evaluating the uniformity of distribution of bellless blast furnaces, and can solve problems such as the lack of further theoretical understanding of production indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

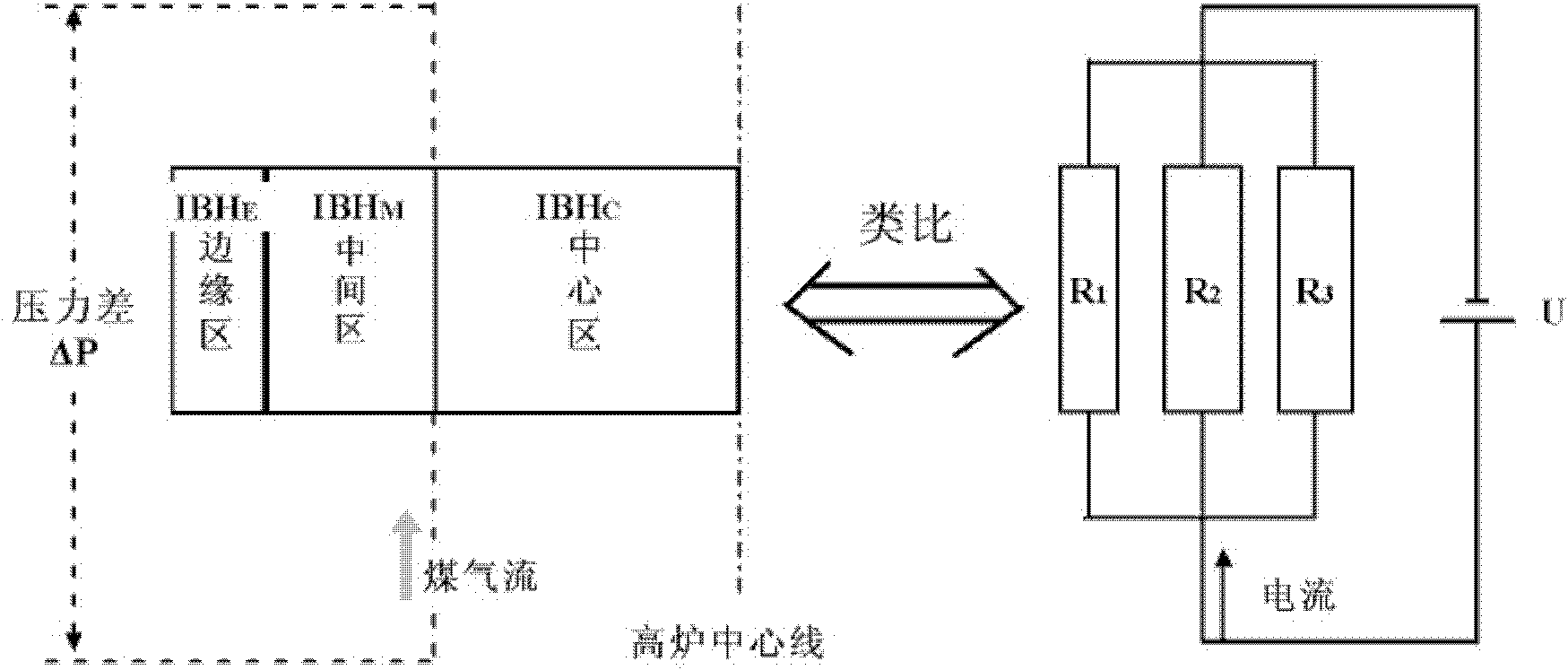

[0043] 1. The distribution uniformity index IBH under different ore-coke ratios

[0044]With a step size of 0.10, simultaneously adjust the ore-coke ratio in the central area and the edge area to increase it from 1.50 to 2.50, and at the same time reduce the ore-coke ratio in the middle area from 2.75 to 1.63. During the adjustment process, the total ore-coke ratio of the column is always guaranteed is 2.00. In this process, the distribution uniformity index of the material column is calculated. The data are summarized in Table 1. It can be seen from the table that with the increase of the ore-coke ratio in the central area and the edge area, and the decrease of the ore-coke ratio in the middle area, The distribution uniformity index IBH increases first and then decreases, and the variation range of the distribution uniformity index IBH tends to be larger at both ends of the curve, while the variation range is smaller in the vicinity of the three areas where the mineral-coke ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com