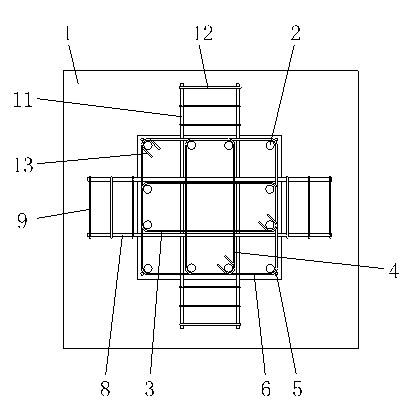

Anti-seismic beam-column joint column hoop fixing method and structure

A fixing method and technology of beam-column joints, which are applied in the directions of earthquake resistance, building components, building structures, etc., can solve the problems of insufficient quantity, dense stirrups outside the column, and uneven spacing, so as to achieve simple structure and process, and ensure construction quality. , the effect of design quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

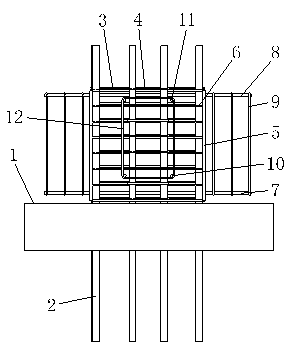

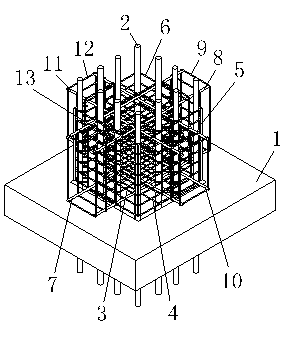

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] A kind of anti-seismic beam-column node column hoop fixing method of the present invention, such as figure 1 , 2 and 3 are shown. The method is constructed in the following steps:

[0031] ①. First, tie or weld a set of inner stirrups according to the designed spacing on a set of column bars 2 that run through the floor formwork surface 1 (see Figure 5 );

[0032] ②. Put the pre-tied or welded column outer stirrup cage from the top of a group of column bars 2 on the outside of a group of column bars 2, and adjust the column outer stirrup cage according to the design requirements (see Figure 4 ), then bind or weld the outer stirrup cage and the inner stirrup;

[0033] ③. Position and connect the X-direction beam reinforcement at one end (refer to Figure 6 ) horizontally pass through the gap between a group of column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com