Conical-surface friction type overrunning clutch

A technology of overrunning clutches and conical surfaces, applied in the direction of friction clutches, clutches, one-way clutches, etc., can solve problems such as high requirements for material and manufacturing consistency, non-self-locking, large slip angle, etc., to improve various performances Indicators, low cost, easy to unlock effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

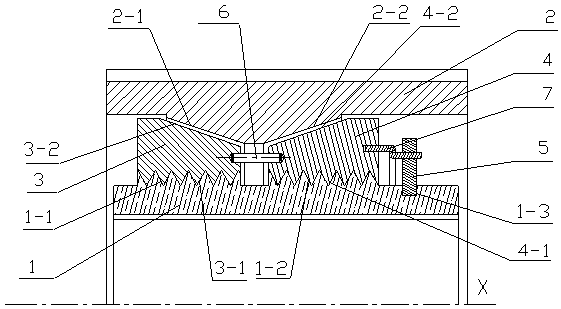

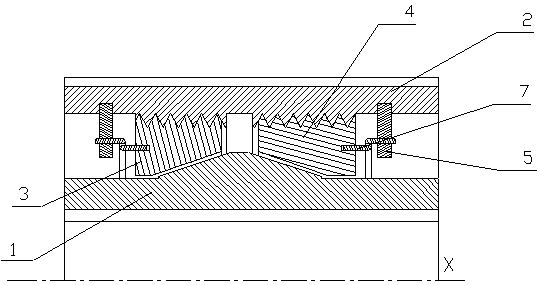

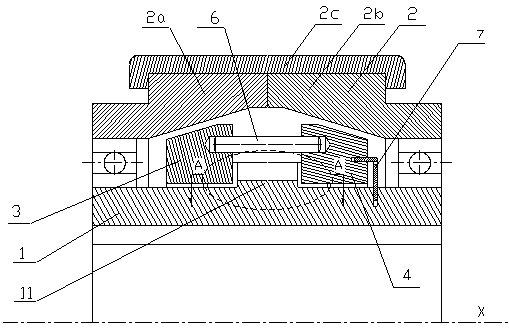

[0046] figure 1 A structure of the conical surface friction overrunning clutch of the present invention is shown, including an inner ring 1 (or called an inner ring assembly), an outer ring 2 (or called an outer ring assembly), a first intermediate ring 3 and a second Intermediate ring 4, intermediate ring axial limiter 5 and pre-tightened elastic member 7;

[0047] The inner ring 1, the outer ring 2, the first intermediate ring 3 and the second intermediate ring 4 have a common axis of rotation, the X axis in the figure; the inner ring 1 adopts an integral inner ring, 1-1 In order to directly process the first external thread on the outer peripheral surface of the inner ring 1, 1-2 is to directly process the second external thread on the outer peripheral surface of the inner ring 1, and a limit ring groove 1-2 is also arranged on the outer peripheral surface of the inner ring. 3. Connecting parts such as straight splines are directly arranged on the inner peripheral surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com