Surge wave pipe structure of nuclear power station voltage stabilizer

A voltage stabilizer and wave tube technology, applied in the field of the voltage stabilizer wave tube structure, can solve the problems of instability, difficulty in reactor plant layout, increased equipment complexity, installation difficulty and maintenance workload, etc., to improve safety, The effect of facilitating the promotion of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

[0020] In a pressurized water reactor nuclear power plant, nuclear fuel is fissioned in the reactor to convert nuclear energy into thermal energy. The heat generated during normal operation of the reactor core is transferred through the coolant system to the steam generator, which produces the saturated steam required to propel the turbo-generator set. The coolant cooled by the working fluid of the steam turbine is pumped back to the reactor by the main pump to absorb heat again, and so on.

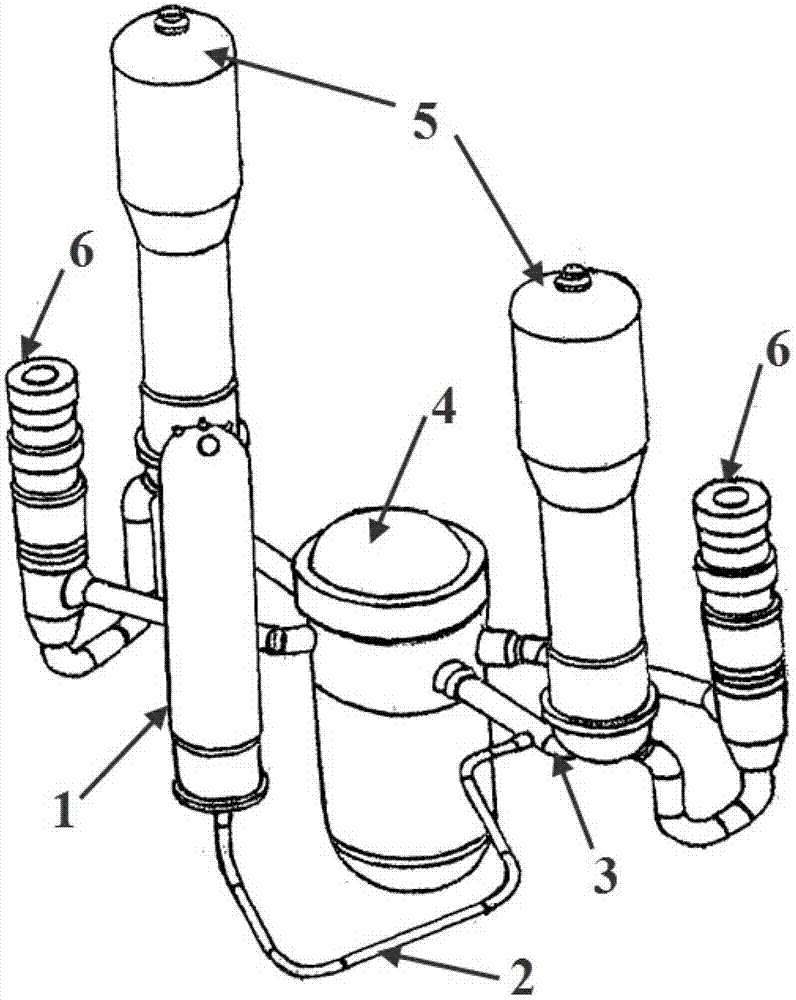

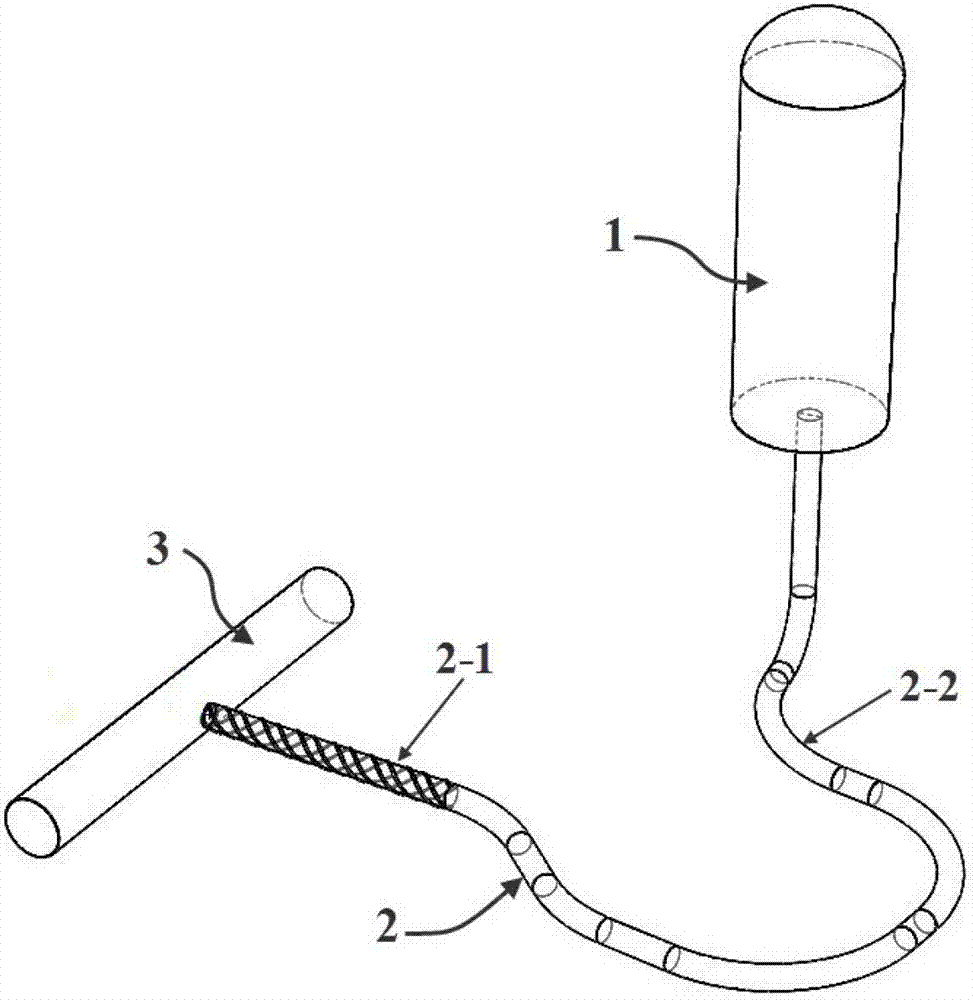

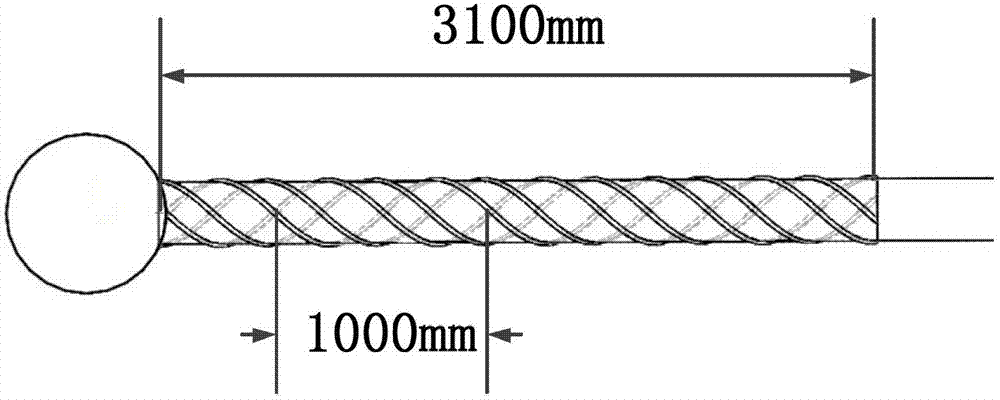

[0021] like figure 1 As shown, the coolant system of the current commercial pressurized water reactor nuclear power plant is generally connected with the reactor pressure vessel 4 by two to four loops, each loop has a main coolant pump 6, a steam generator 5 . The entire system shares a single voltage regulator 1. The reactor coolant system relies on the pressure regulator 1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com