Hand-free ternary inspection machine

A technology of inspection machine and lifting mechanism, applied in the field of chip welding and wire bonding, can solve the problems of increasing artificially bumped products, deformation of welding wires in the state of chip bonding, and no direct connection, so as to avoid manual direct contact with packaged products and satisfy the The effect of safety protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

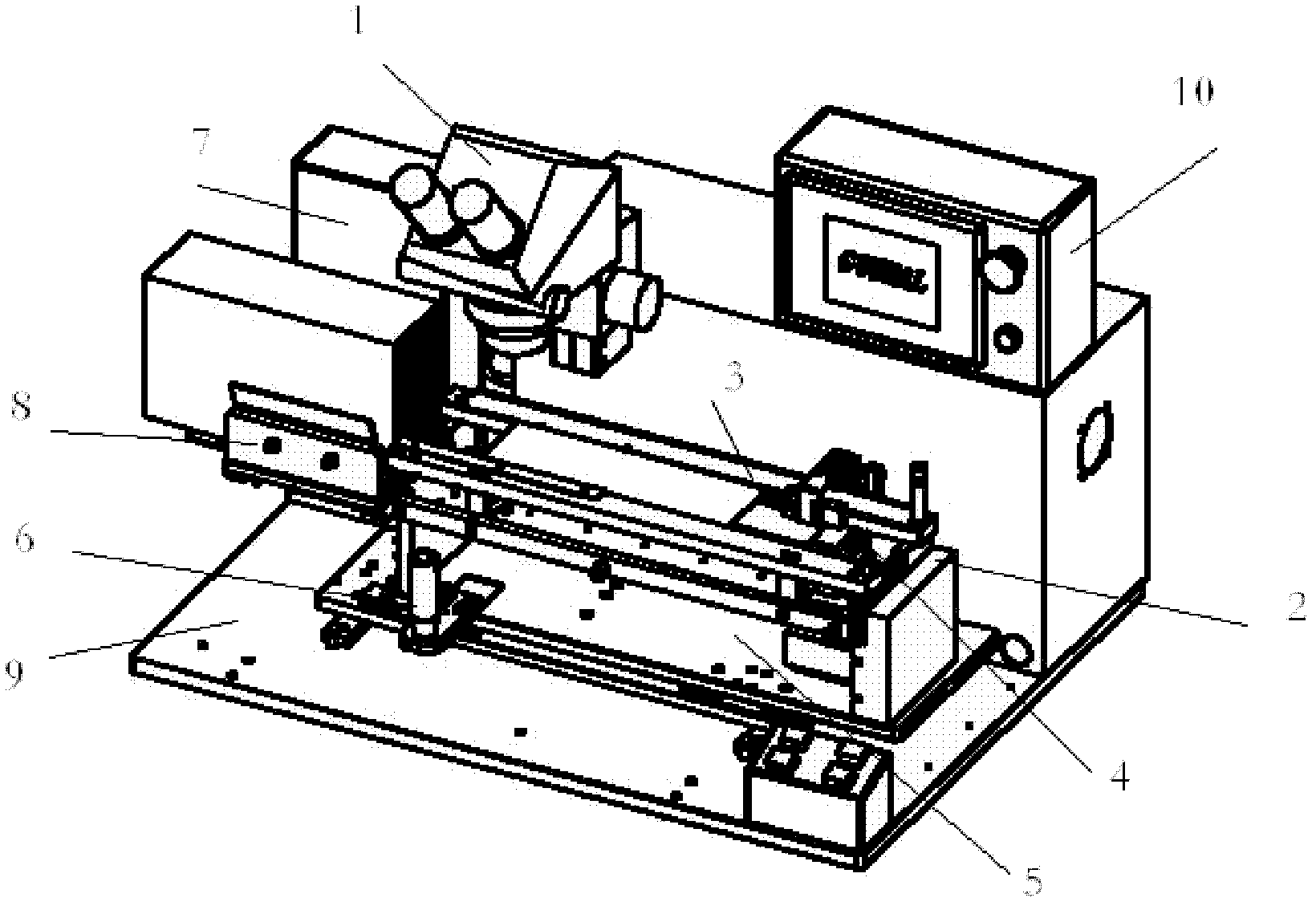

[0011] Depend on figure 1 It can be seen that the present invention includes: a stereoscopic microscope 1; also includes: an X-axis guide rail 2 and a moving claw 3 on the X-axis guide rail 2; the X-axis guide rail 2 can move in steps; The claw 3 clamps the material strip through a pneumatic feeding mechanism 4 arranged on the X-axis guide rail; a guide rail width adjustment assembly 5 is also arranged on the X-axis guide rail 2; it also includes: an X, Y manual moving table 6 ; The described X, Y manual mobile platform 6 is placed on the base plate 9; a material box elevating mechanism 7 arranged on the X, Y manual mobile platform 6 and a material box holder arranged on the material box elevating mechanism 7 8; The X-axis guide rail 2, the material box lifting mechanism 7 and the pneumatic feeding mechanism 4 are connected to a PLC 10 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com