High-capacity lithium battery

A lithium battery, high-capacity technology, used in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as low assembly efficiency and inability to meet fully automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

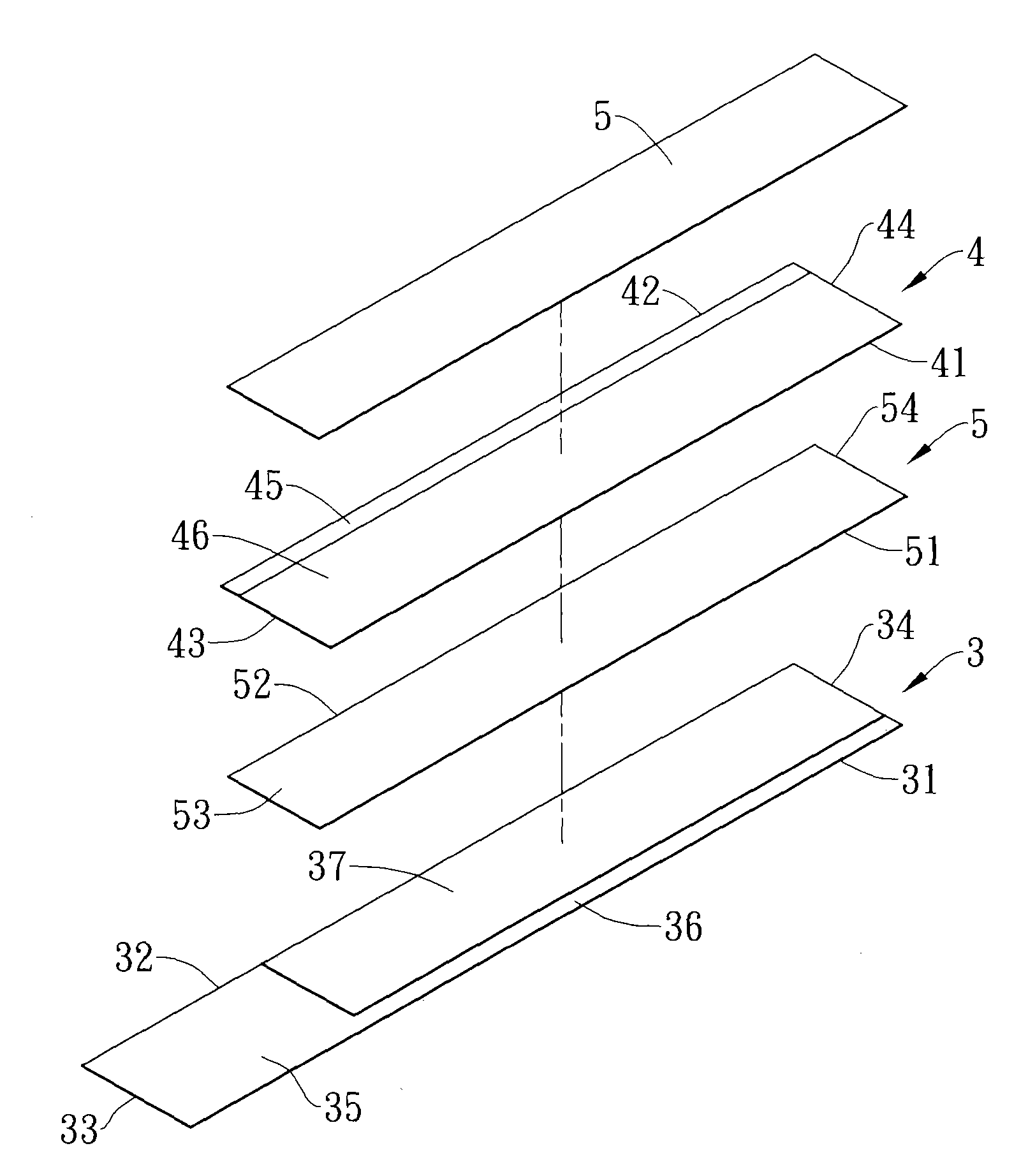

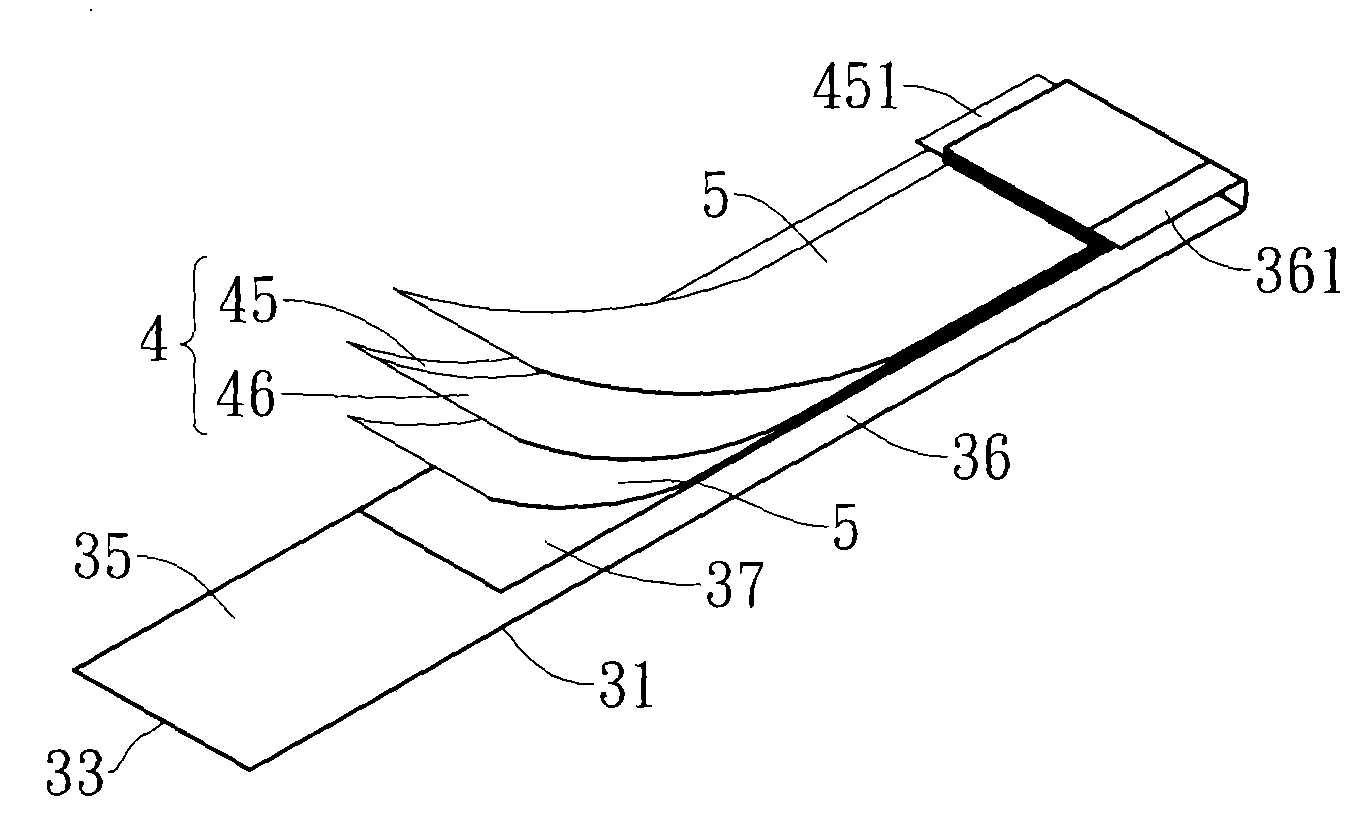

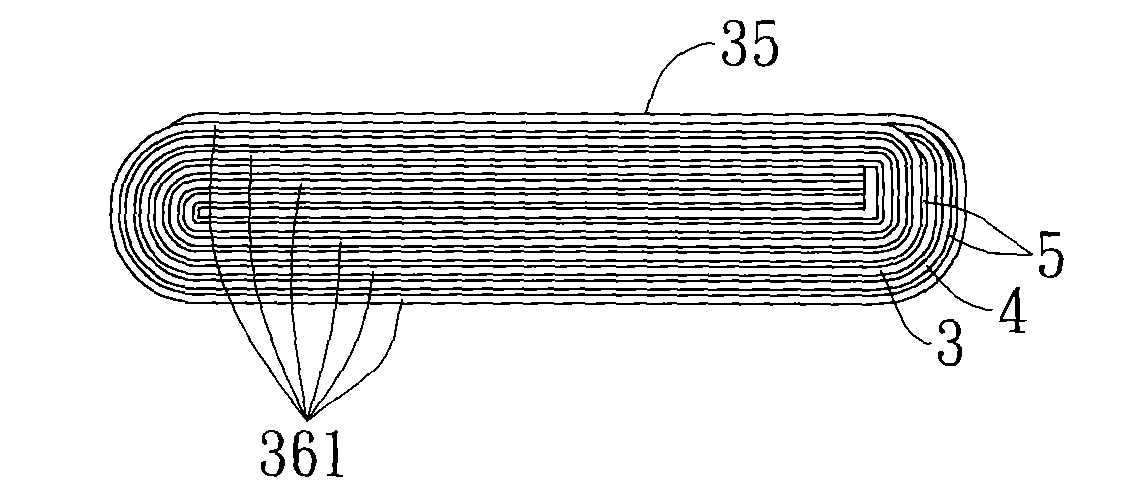

[0019] see figure 1 , 4 As shown, it is a preferred embodiment of the high-capacity lithium battery 1 of the present invention, and the positive electrode sheet 3 , the negative electrode sheet 4 , the separator 5 and the electrolyte solution 6 are covered with the packaging structure 2 . Wherein, the positive electrode sheet 3, the negative electrode sheet 4, and the separator 5 are elongated, so that the positive electrode sheet 3, the negative electrode sheet 4, and the separator 5 respectively have a first long side (31, 41, 51), a parallel The second long side (32, 42, 52) of the first long side (31, 41, 51), a first short side (33, 43, 53) and a parallel to the first short side (33, 43, 53) the second short side (34, 44, 54).

[0020] During implementation, the positive electrode sheet 3 is a strip-shaped aluminum foil, and the positive electrode sheet 3 can also be a positive electrode collector of other metal materials. The positive electrode sheet 3 forms an extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com