Multi-functional liquid pesticide spray machine

A sprayer, multi-functional technology, applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of unacceptable and unsatisfactory farmers, etc., to achieve high production efficiency and good spraying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

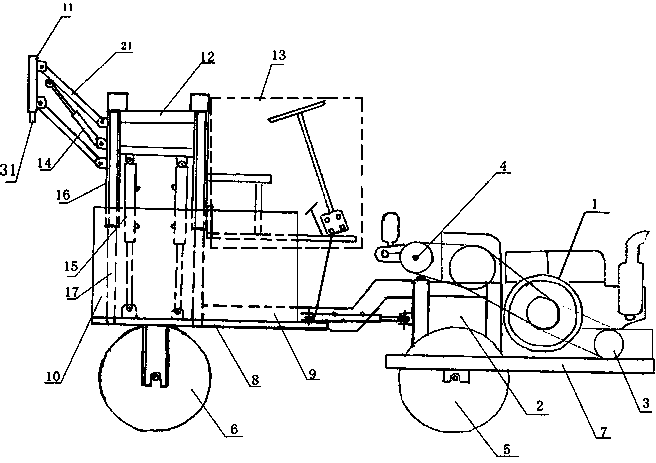

[0021] Such as Figure 1-3 As shown, a multifunctional liquid spraying machine includes a diesel engine, a gearbox, a drive shaft, a hydraulic oil pump, a spraying pump, front wheels, left wheels, right wheels, front frame, middle frame, left frame, right Frame, left medicine box, right medicine box, folding spraying frame, driving platform, multiple spraying heads, four spraying frame arms and two spraying frame lifting hydraulic cylinders, diesel engine installed on the front frame, hydraulic The oil pump is installed at the front end of the front frame, the diesel engine is connected to the hydraulic oil pump through a belt, the front wheels are installed at the lower end of the front frame, and a gearbox is installed on the frame, the diesel engine is connected to the gearbox through a clutch, and the gearbox is connected to the front wheels through a drive shaft. connection, the spray pump is connected with the diesel engine through a belt; the right wheel is installed at...

Embodiment 2

[0023] The sprayer also includes a steering hydraulic cylinder, one end of the steering hydraulic cylinder is connected to the front end of the middle frame, the other end of the steering hydraulic cylinder is connected to the rear end of the front frame, the hydraulic oil pump is connected to the steering hydraulic cylinder through a hydraulic oil pipe, and the steering wheel Control the expansion and contraction of the steering hydraulic cylinder.

Embodiment 3

[0025]This embodiment is the same as Embodiment 1, the difference is that: the six top support frame lifting hydraulic cylinders are replaced by six lead screws, and the lifting of the six lead screws is manually controlled, thereby controlling the lifting of the top support frame.

[0026] The sprayer has the following functions:

[0027] (1) The wheelbase is adjustable, and the normal operation can be completed from 1.3m to 2.6m. It can also complete the spraying of special crops such as corn, flue-cured tobacco, and cauliflower in large ridges.

[0028] (2) The working height is adjustable, with a minimum of 1.7 meters and a maximum of 2.2 meters. When it is raised, the driver's cab is fully raised, and it is also lowered simultaneously when it is lowered.

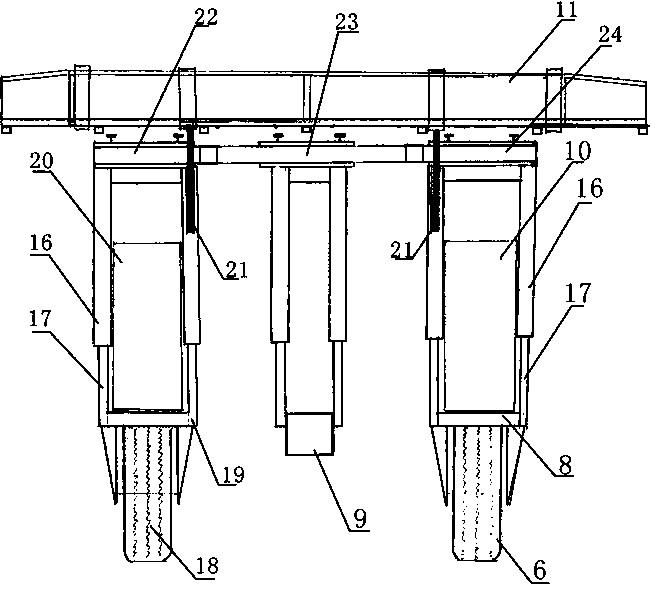

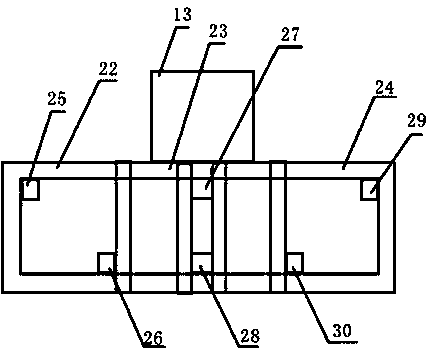

[0029] (3) The frame is raised and lowered, and 24 square steels of different specifications are used to process 12 casings, which are divided into three groups of four, the body is a group of brackets, and the two main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com