Concrete mixer

A technology for concrete mixer trucks and mixing tanks, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., and can solve the problem of the center of gravity deviation of the upper part of the concrete mixer truck, affecting the life and safety of the whole vehicle, and affecting driving comfort issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the concrete mixer truck proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. The details are as follows.

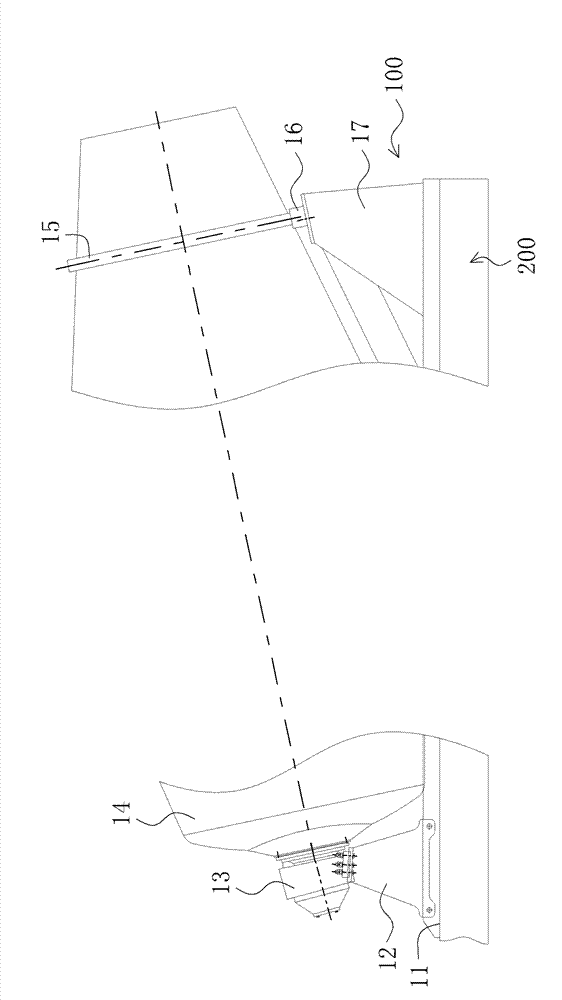

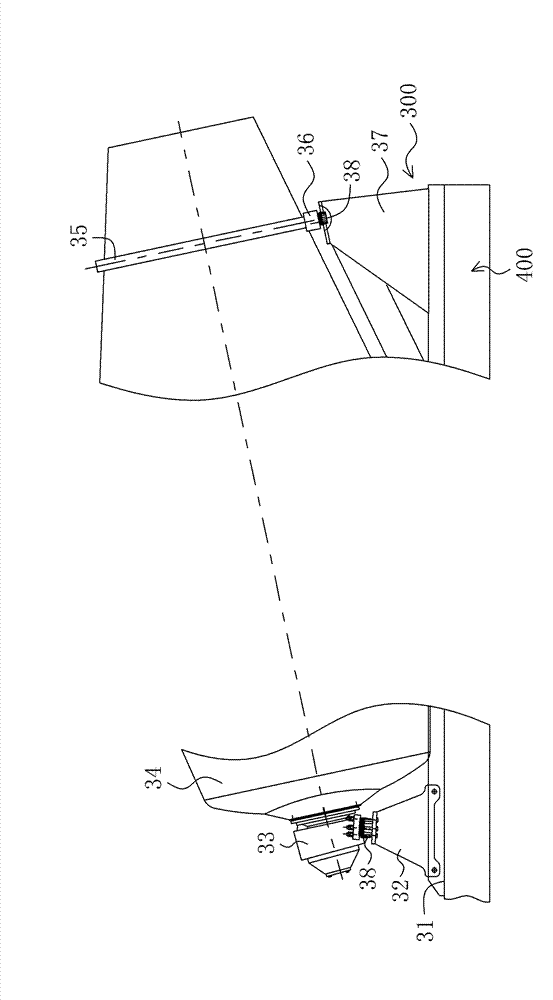

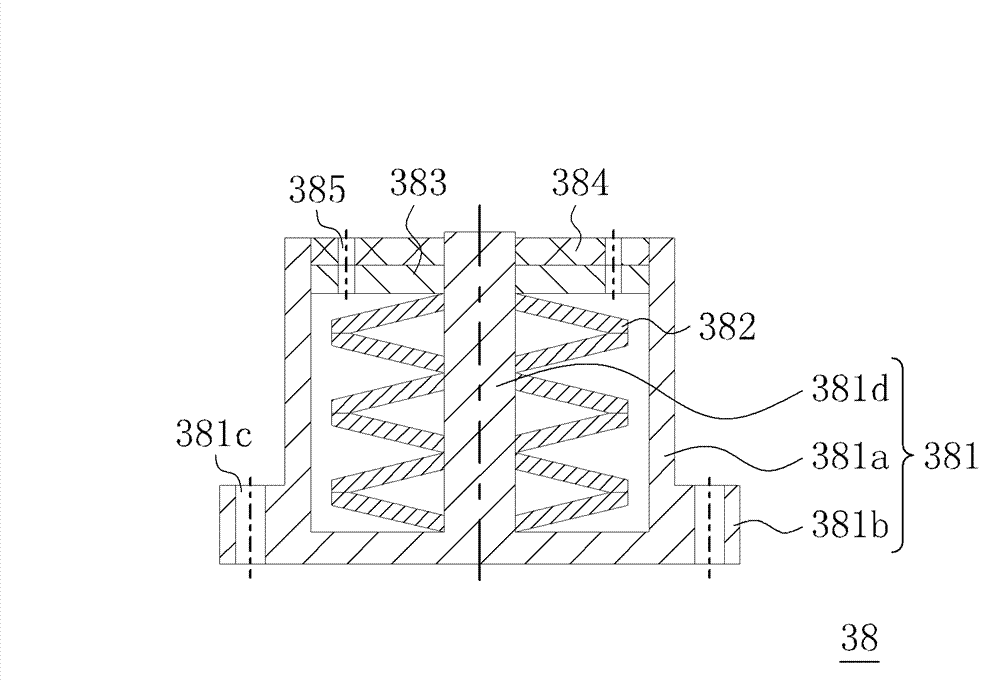

[0022] The concrete mixer truck of the present invention includes an upper part 300 and a car chassis 400, and the upper part 300 is fixed to the car chassis 400 for providing the mixed concrete. figure 2 Shown is a schematic diagram of an embodiment of the upper body part of the concrete mixer truck of the present invention. Such as figure 2 As shown, the upper part 300 includes a subframe 31 , a front bracket 32 , a speed reducer 33 , a mixing tank 34 , a guide rail 35 , a supporting wheel 36 , a rear bracket 37 and a plurality of elastic damping devices 38 . Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com