Antiwear additive for lubricating oil

A technology of lubricating oil and additives, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve problems such as unreported, application restrictions, etc., and achieve the effect of improving anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

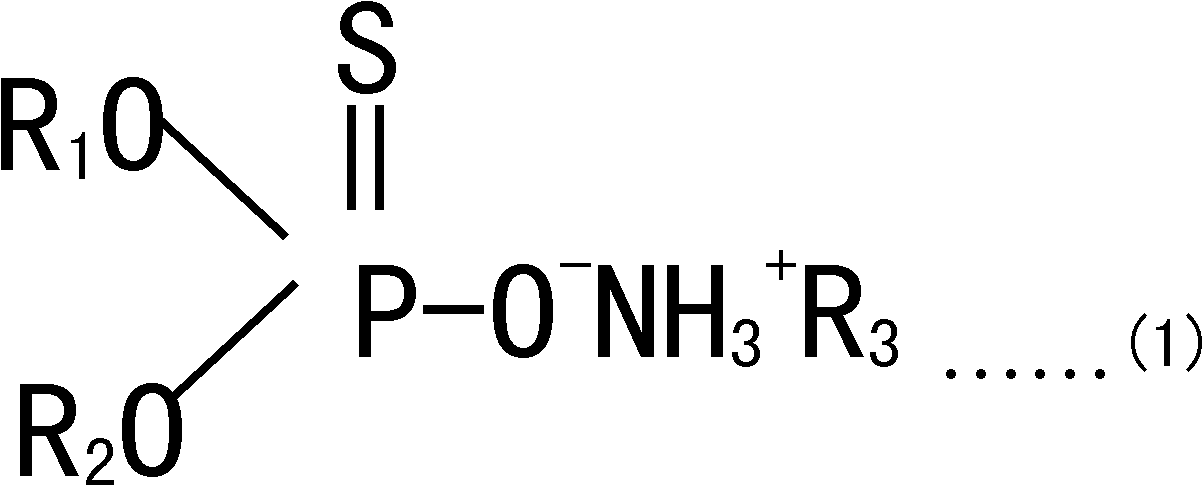

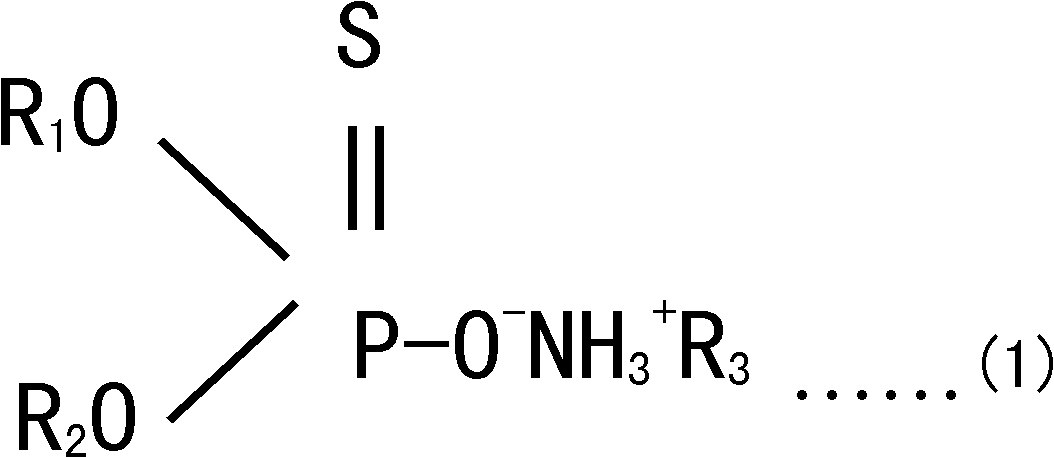

Method used

Image

Examples

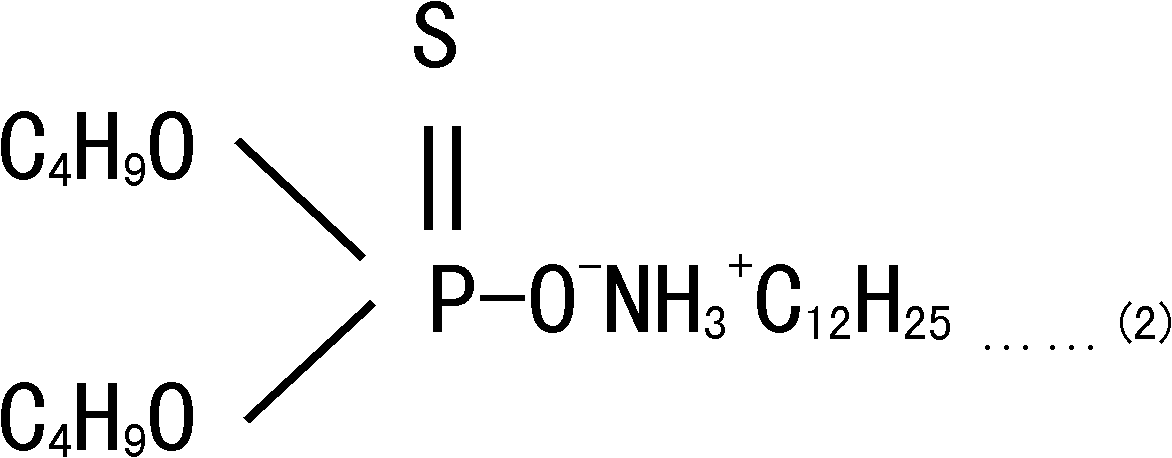

Embodiment 1

[0018] 0.45% (mass) di-n-butyl phosphorothioate dodecylamine salt (compound (2)) is added in the 80W-90GL-5 vehicle gear oil complete formula that total dosage is 3.8% (mass), passed L-37 , L-42, L-33, L-60-1 four bench tests, and the anti-wear performance of the oil is 15% higher than that of GL-5 oil containing ZDDP.

Embodiment 2

[0020] Containing 0.50% (mass) di-n-butyl phosphorothioate octadecylamine salt (compound (3)) in the full formula of 320 heavy-duty industrial gear oil, the formula is formulated with 2.0% (mass) dosage of 320 heavy The heavy-duty industrial gear oil passed the FAG FE-8 bearing wear test, while the 320 heavy-duty industrial gear oil with the same formulation using ZDDP failed the FAG FE-8 bearing wear test.

Embodiment 3

[0022] The full formula of ashless hydraulic oil contains 0.20% (mass) of di-n-octyl phosphorothioate dodecylamine salt (compound (5)), and the formula is formulated with 0.80% (mass) of HM anti-wear The hydraulic oil has passed the V104 vane pump wear bench test, indicating that compound (5) has excellent anti-wear performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com