Method for surface treatment of carbide cutter by broad-beam N ion and device thereof

A hard alloy, surface treatment technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of easy peeling, easy change of tool geometry, coating material and cemented carbide tool substrate Insufficient bonding force on the surface of the material, etc., to achieve the effect of improving cutting characteristics, increasing hardness, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

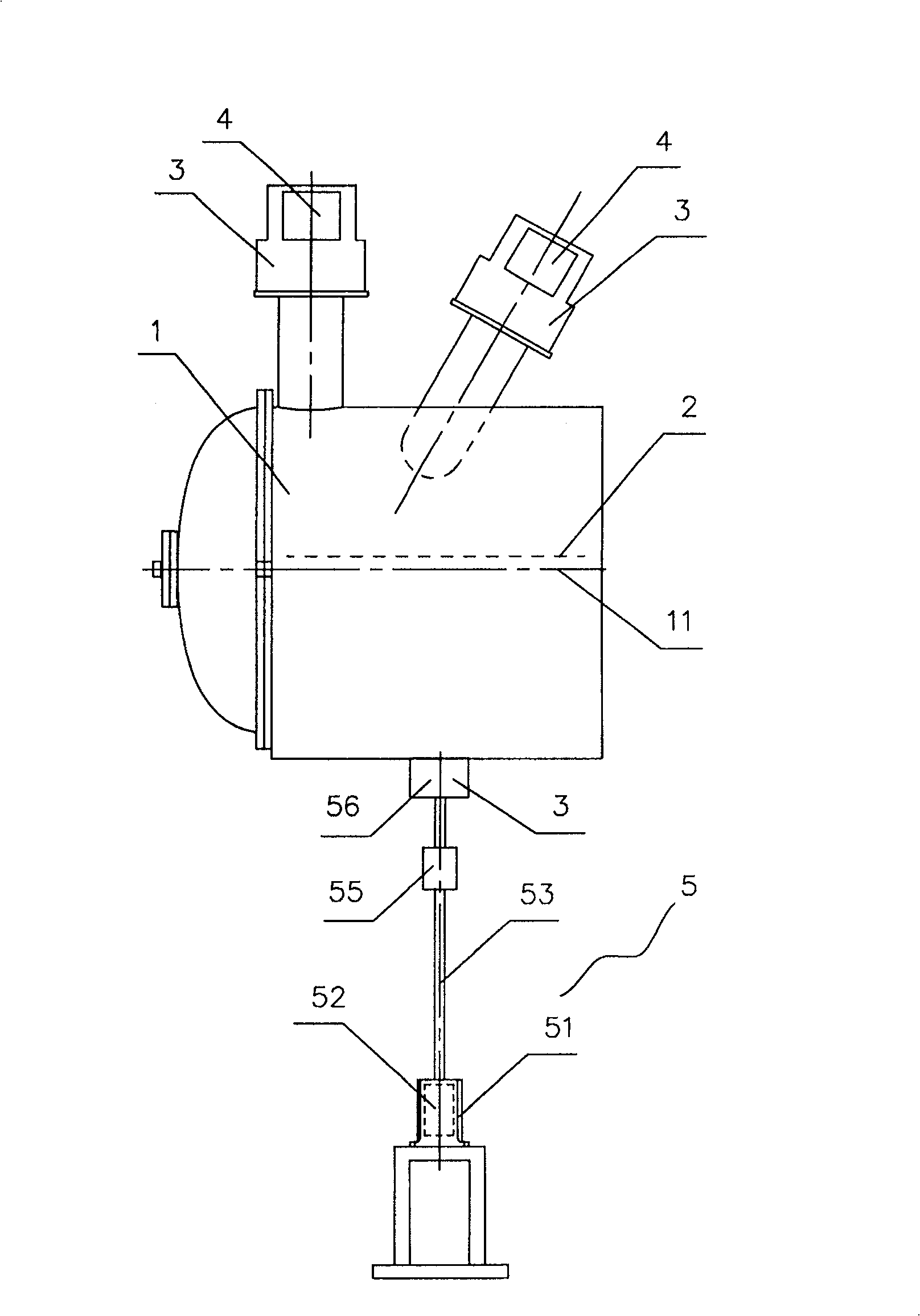

[0016] The invention uses an ion implanter to treat the surface of a cemented carbide tool with wide-beam N ions. The ion implanter has been improved on the basis of the original ion implanter. It adopts a wide-beam nitrogen ion source (beam spot diameter 120-150mm), removes the mass selection and ion beam scanning system, and sets four flanges on the vacuum chamber. And the movable workpiece target platform, and a rotating system is added under the vacuum chamber, so that the workpiece target platform and the target disc on the workpiece target platform can rotate with the rotation of the rotating system.

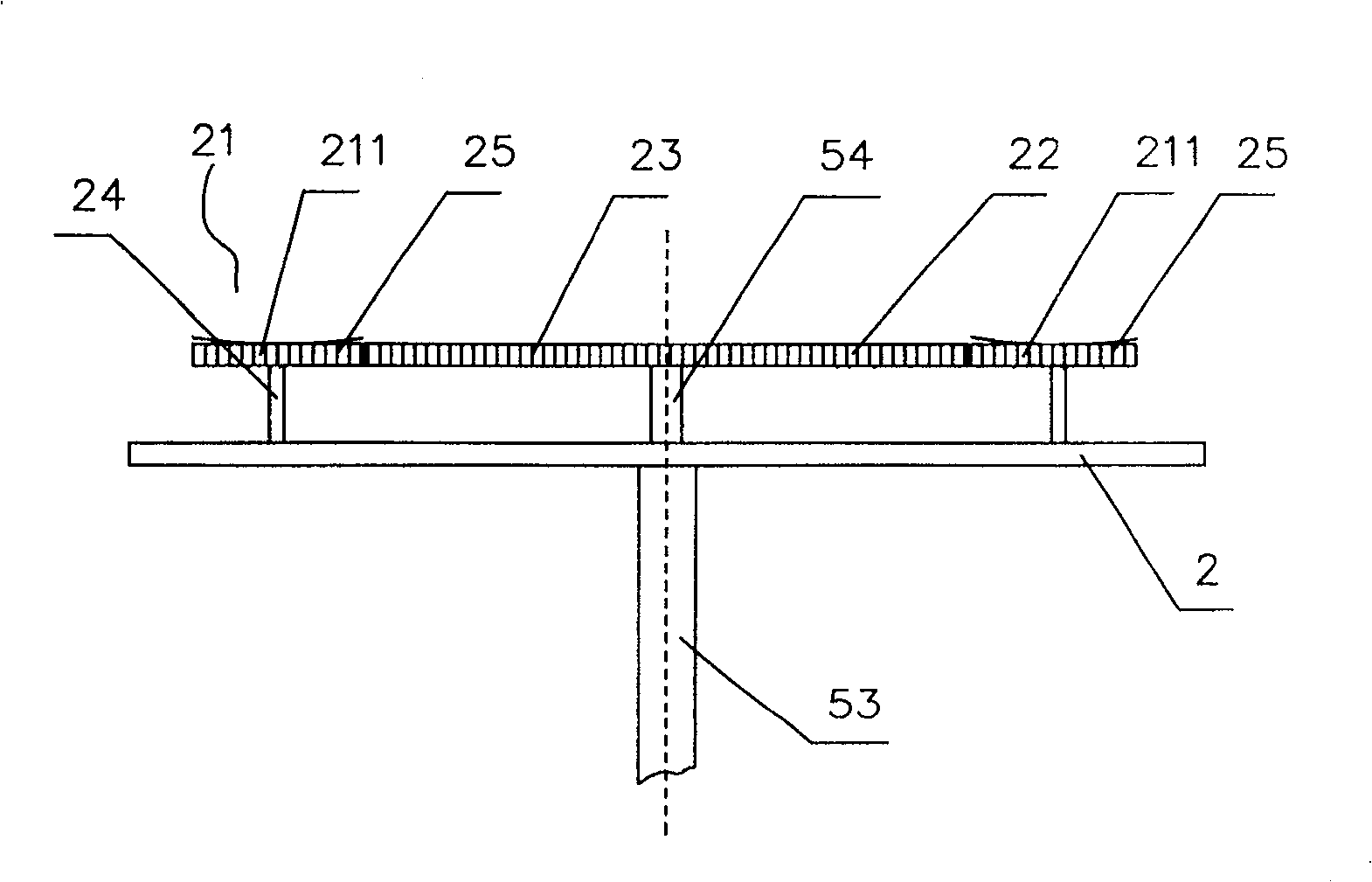

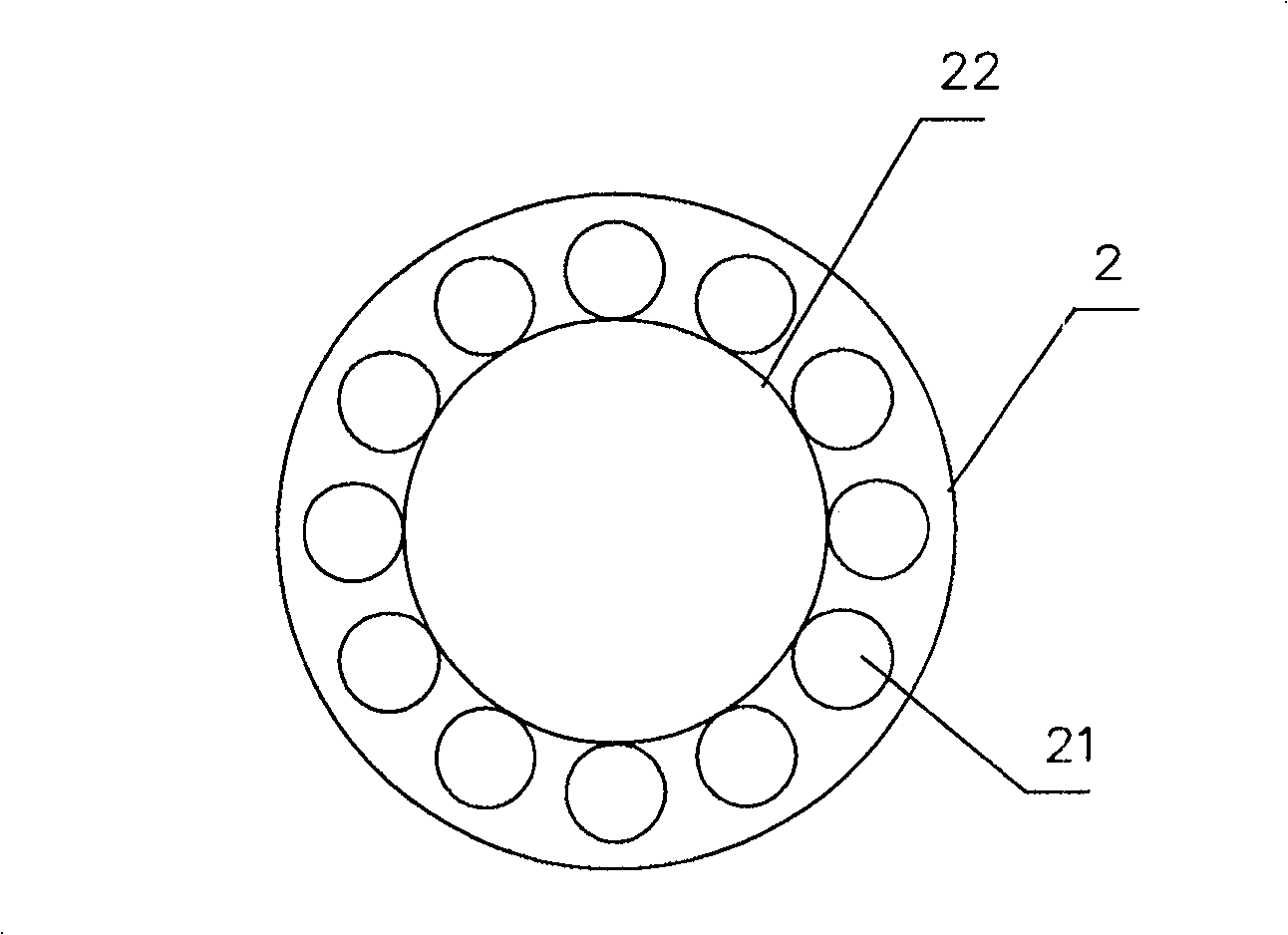

[0017] see Figure 1-Figure 3 As shown, the above-mentioned ion implanter includes a vacuum chamber 1, a workpiece target stage 2 provided with a target disk 21, and the workpiece target stage 2 is located on a horizontal plane above the centerline 11 of the vacuum chamber, preferably on a horizontal plane 35 mm away from the centerline; The vacuum chamber 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com