A method for anti-scouring, anti-abrasion, and bursting of high-temperature and high-pressure drainage pipelines in thermal power plants

A drainage pipeline, high temperature and high pressure technology, applied in the pipeline system, steam trap, gas/liquid distribution and storage, etc., can solve the problems of consuming a lot of manpower and material resources, threatening the safety of personnel and equipment, and abrasion of drainage pipelines, etc., to achieve improvement Anti-wear properties, improved system safety, and reduced scouring wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

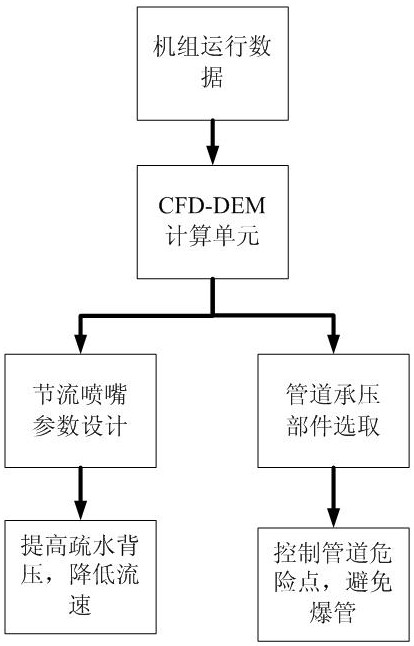

[0031] A method for anti-scouring, anti-wear and bursting of high-temperature and high-pressure drainage pipelines in thermal power plants, such as image 3 As shown, it specifically includes the following process:

[0032] 1) Based on the CFD-DEM calculation fluid method, a three-dimensional steam-water two-phase model of the high-temperature and high-pressure drain pipeline is established, and the main steam parameters are obtained from the SIS real-time production database by the communication program, including the main steam temperature, the main steam pressure, the main steam flow rate, and the opening of the drain valve. Unit operating parameters such as temperature and unit load. The CFD-DEM three-dimensional calculation unit can accurately obtain the internal details of the high-temperature and high-pressure drain pipeline, including temperature field distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com