Washing machine with ultrasonic devices

A washing machine and ultrasonic technology, applied in the field of washing machines, can solve problems such as unsatisfactory effect and large loss, and achieve the effects of simple structure, increased sense of identity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

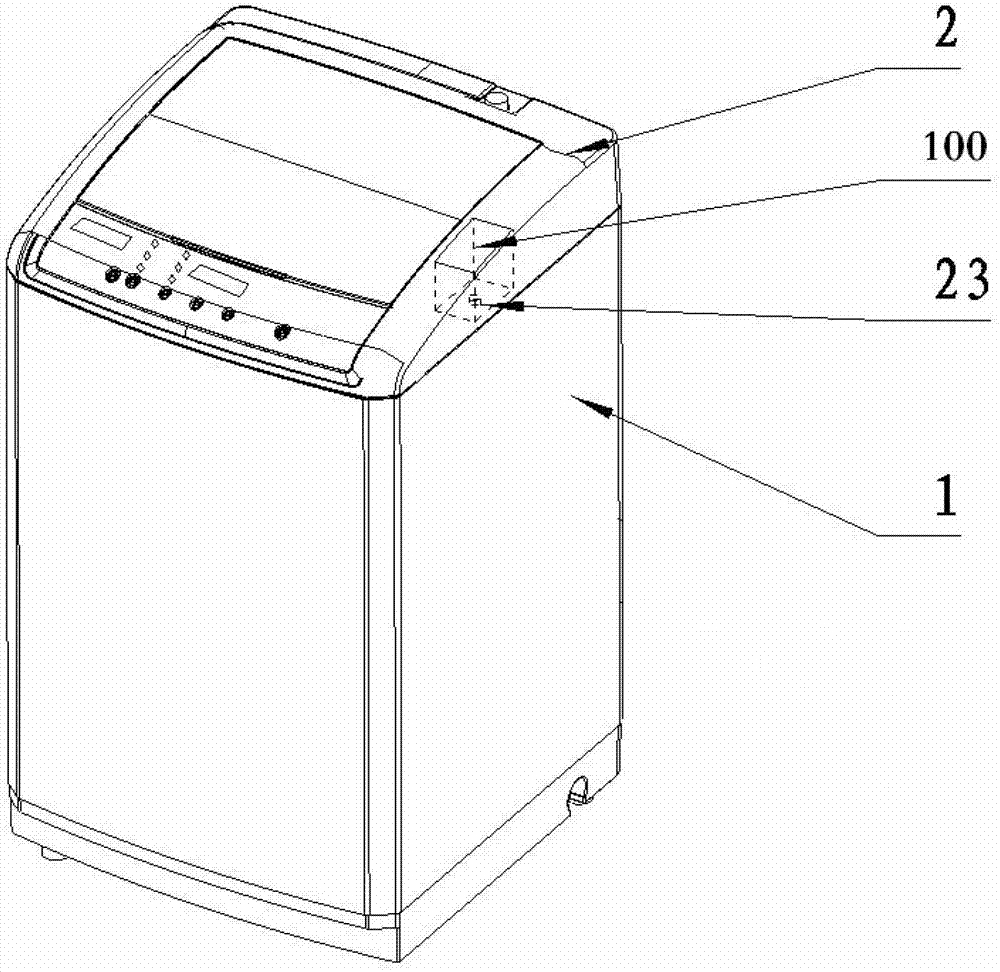

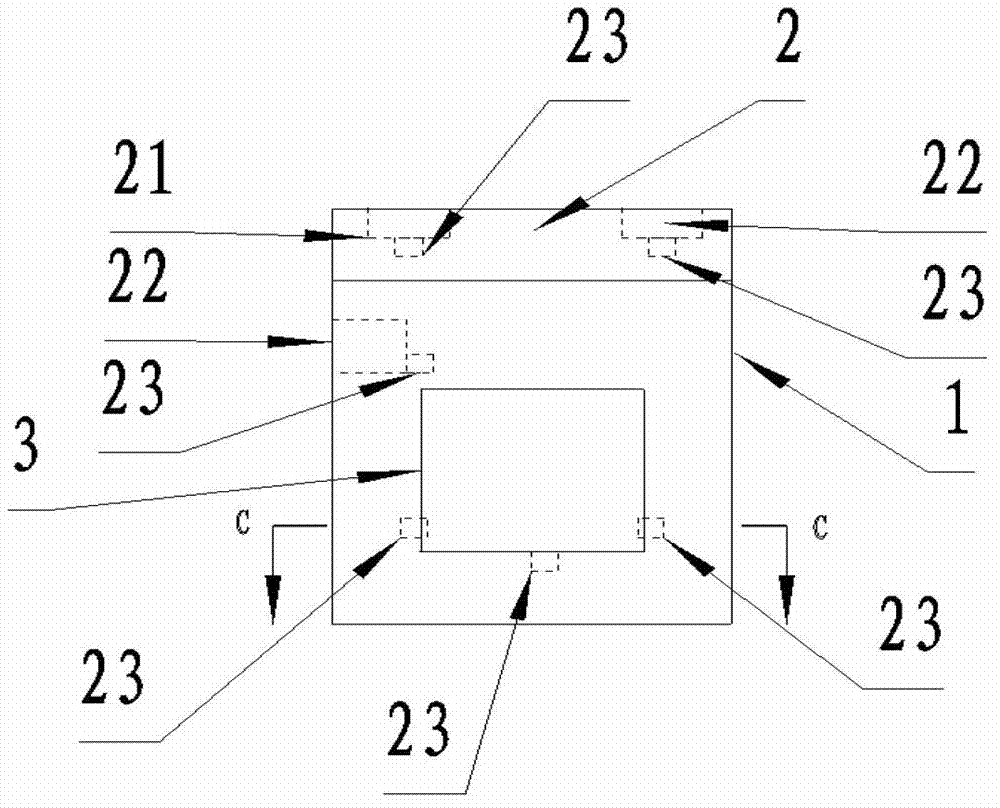

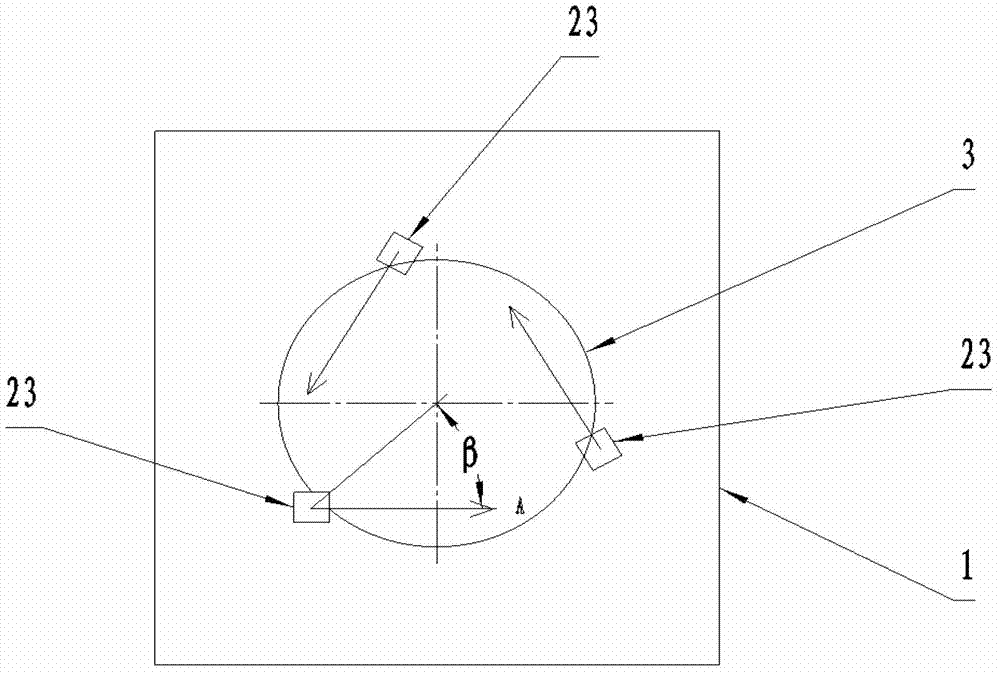

[0038] The washing machine described in this embodiment is a vertical drum washing machine, and the vertical drum washing machine is a fully automatic pulsator washing machine, see figure 1 with Figure 7 . The washing machine comprises a washing machine shell 1, an inner cylinder and an outer cylinder 3 arranged in the washing machine, and an ultrasonic cleaning device 100 is independently arranged on the washing machine; the ultrasonic cleaning device has a liquid containing space, and the liquid containing space has an opening 101; the liquid containing space It is used to accommodate liquid medium and objects to be cleaned; the liquid containing space is provided on the washing machine independently of the inner cylinder and the outer cylinder 3, so as to make full use of the space of the washing machine.

[0039] see Figure 7 , in the ultrasonic cleaning device 100 of the present invention, the liquid containing space is a washing box 22, the washing box 22 includes a ...

Embodiment 2

[0055] Compared with Embodiment 1, this embodiment mainly introduces the application of the ultrasonic generating device in the drum washing machine, see Figure 4 . The washing machine includes a washing machine shell 1, an inner cylinder and an outer cylinder 3 arranged inside the washing machine, and a table panel 4 arranged on the top of the washing machine. The table panel 4 is provided with a washing box 22, and the installation method of the washing box 22 can be the same as that of the existing drum drawer. Type detergent box structure, or the way of opening the cover, the washing box is provided with an ultrasonic generator 23. The ultrasonic generating device 23 is arranged at the bottom of the washing box, or the ultrasonic generating device 23 is arranged at the side wall of the washing box.

[0056] The effect of the washing box 22 is similar to that of Embodiment 1, and it is also mainly used for washing small items such as: gold and silver jewelry, glasses, sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com